-

-

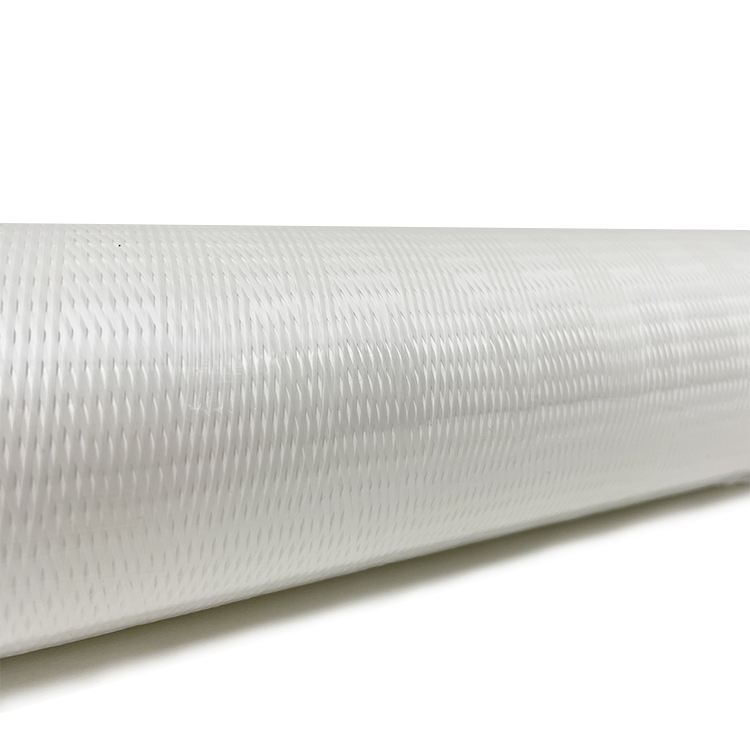

500D - PTFE Filament Yarn - Good temperature resistance - High Strength

- Code:TC-PT500D

- Material:100% PTFE

- Weight:1.2kg/cone

- Function:Waterproof, Low Shrinkage, High Temperature Resistant, Chemical-Resistant, Abrasion-Resistant, High Tenacity, flame retardant

- Color:White

- Weave:Raw

SEND INQUIRY

Product Properties

The surface of the PTFE material has a spider-web-like microporous structure, which has very complex changes in the three-dimensional structure, such as network connection, hole inlay, and pore channel bending, so it has excellent surface filtration function. The nano-mask produced by this material has the characteristics of high barrier efficiency, long service life, light and breathable

PTFE filament fiber has the characteristics of good temperature resistance, chemical resistance, high tensile strength, low shrinkage, and excellent wear resistance. Now based on PTFE filament fiber, it can be processed into various high-performance mesh fabrics, base fabrics, sewing threads, dental floss, seal tape, membrane structures and other products.

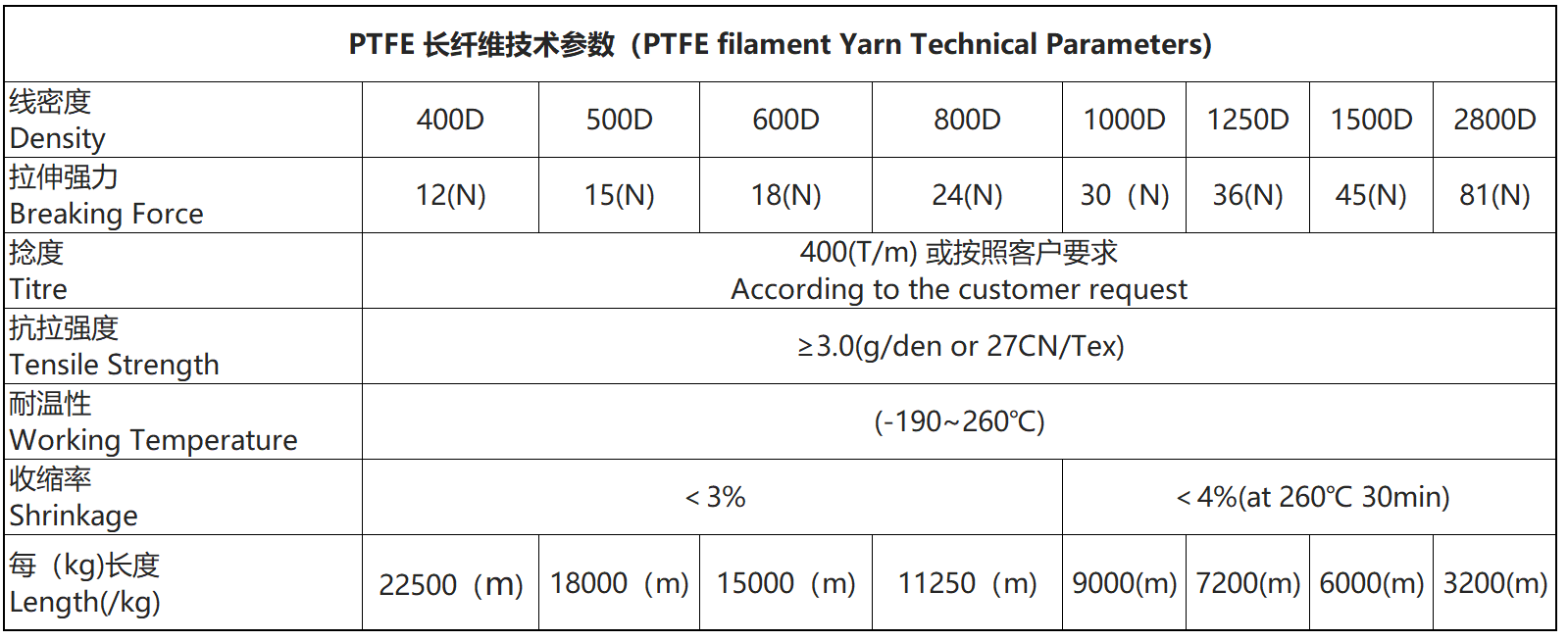

Good temperature resistance, very wide temperature range, long-term use temperature is -190-260℃

High Tenacity, Abrasion Resistance, Water Resistant

Material: |

100% PTFE | Density: | 500D |

| Color: | white | Weight : | 1.2kg/cone |

| Yarn Type: |

Filament | Shrinkage |

≤3% ≤4%(at 260℃ 30min) |

| Breaking Strength Tenacity: | 27cN/tex | Length: | 18000m/kg |

| Breaking Strength(cN): | 1500 | Twist | NA |

Material: |

100% PTFE |

| Color: | White |

| Yarn Type: | Filament |

| Breaking Strength Tenacity: | 27cN/tex |

| Breaking Strength(cN): | 1500 |

| Density: | 500D |

| Weight : | 1.2kg/cone |

| Shrinkage: |

≤3% ≤4%(at 260℃ 30min) |

| Length: | 18000m/kg |

| Twist: | NA |

Product Description

PTFE fiber is a synthetic fiber made of polytetrafluoroethylene, which is spun or made into a film and then cut or fibrillated. The relative molecular mass of polytetrafluoroethylene is relatively large, and the lowest is hundreds of thousands. The highest is more than 10 million, generally millions. PTFE polymers generally have a crystallinity of 90-95%. Due to the strong polarity of the fluorine atom, the polymer exhibits extremely stable physical and chemical properties. Its long-term use temperature is -190-260℃, and its melting temperature is 327-342 degrees; it is still soft at minus 100 degrees; it also has the best aging life and the smallest friction coefficient among plastics.

500D PTFE Filament

Features:

PTFE filament are fiber-based,can be processed into various types of high-performance mesh,

PTFE staple is widely used in waste incineration power plant dust,cement dust,building materials

PTFE sewing thread is twined and twisted of filament fibers,

PTFE is the most chemical resistance of all known plastic. It does not age : It has the lowest coefficient of friction of all known solid materials and a wide range of practicable temperature from -190°c~+260°c.

| Content: | 100% PTFE |

| Specification : | 400D, 500D, 600D, 800D, 1000D, 1250D, 1500, 2800D etc. |

| Color: | White |

| Use: | Sewing, Cross Stitch, Embroidey,Hand Knitting, Weaving |

| Feature: | Good temperature resistance, chemical resistance, high tensile strength, low shrinkage, and excellent wear resistance |

| MOQ: | 10 kilograms |

| Meet standard : | AATCC/ASTM, EN, ISO, GB, AS |

| Application : | High-performance mesh fabrics, base fabrics, sewing threads, dental floss, seal tape, membrane structures and other products. |

Parameters of the same type

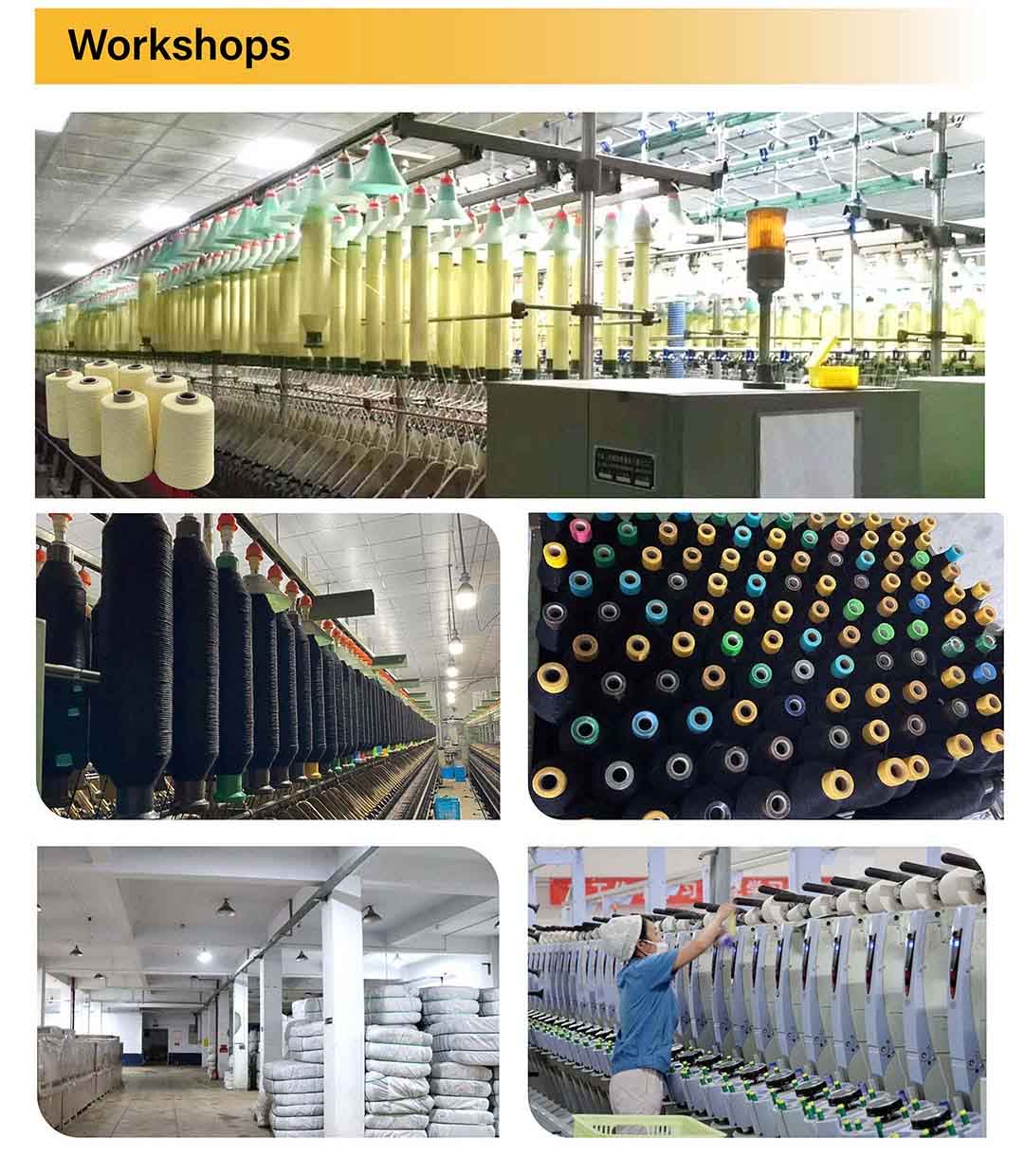

Company Information