-

-

20S1 - 100% Pre-oxidized PAN Yarn - Raw Materials Flame retardant

- Code:TC-PY201

- Material:100% Pre-oxidized pan fiber

- Weight:1kg/cone

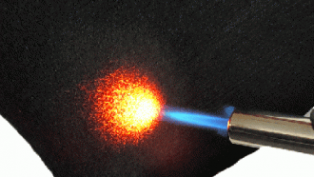

- Function:High Temperature Resistant, Flame Retardant, Fire-Proof

- Color:Black

- Count:20S1

SEND INQUIRY

Material: |

100% panox yarn | Yarn Count: | 20S1 |

| Properties: | High temperature resistant | Weight : | 1kg/cone |

|

Spinning process: |

Ring spinning | LOI: | >42% |

| Breaking Strength: | >4CN/TEX | Breaking Elongation%: | 13.59% |

Material: |

100% panox yarn |

| Properties: | High temperature resistant |

|

Spinning process: |

Ring spinning |

| Breaking Strength: | >4CN/TEX |

| Yarn Count: | 20S1 |

| Weight : | 1kg/cone |

| LOI: | 42% |

| Breaking Elongation%: | 13.59% |

Product Description

Flame-retardant yarns are widely used in the industrial field, mainly including the following aspects:

- Protective clothing: In the petrochemical, metallurgical, electric power and other industries, there are risks such as fire and explosion, and workers need to wear protective clothing with flame-retardant function. For example, protective clothing made of flame-retardant acrylic cotton blended fabric can effectively prevent the spread of flames and protect workers from harm.

- Industrial fabrics: Some factory equipment needs to be covered or isolated. Industrial fabrics woven with flame-retardant yarns, such as tarpaulins and equipment covers, can prevent sparks, slag, etc. from causing fires and ensure production safety.

- Mineral conveyor belts: During mineral mining and transportation, conveyor belts are prone to heat and sparks due to friction, causing fires. Conveyor belts made of flame-retardant yarns, such as 20 and 21s polyester yarns, can reduce the risk of fire and improve production efficiency.

- Filter materials: In the chemical, pharmaceutical, environmental protection and other industries, filter materials must be flame-retardant to prevent burning due to contact with fire sources during the filtration process. Filter cloth and filter screen made of flame-retardant yarn can improve the safety of use while ensuring the filtering effect.

- Aerospace: Flame-retardant yarn is required for the decorative materials and seat fabrics inside the aircraft to ensure flight safety. For example, aramid flame-retardant yarn has the characteristics of high strength, high temperature resistance, and flame retardancy, and can be used to manufacture aircraft structural components and interior materials.

- Automobile manufacturing: The use of flame-retardant yarn in car seats, interior fabrics, seat belts, etc. can reduce the harm caused by fire. For example, flame-retardant polyester yarn can improve the fire resistance of the car while ensuring comfort.

- Electronics and electrical: In the production process of electronic equipment, some parts need to use packaging materials or insulating materials made of flame-retardant yarn to prevent fires caused by faults such as short circuits and protect the safety of equipment and personnel.

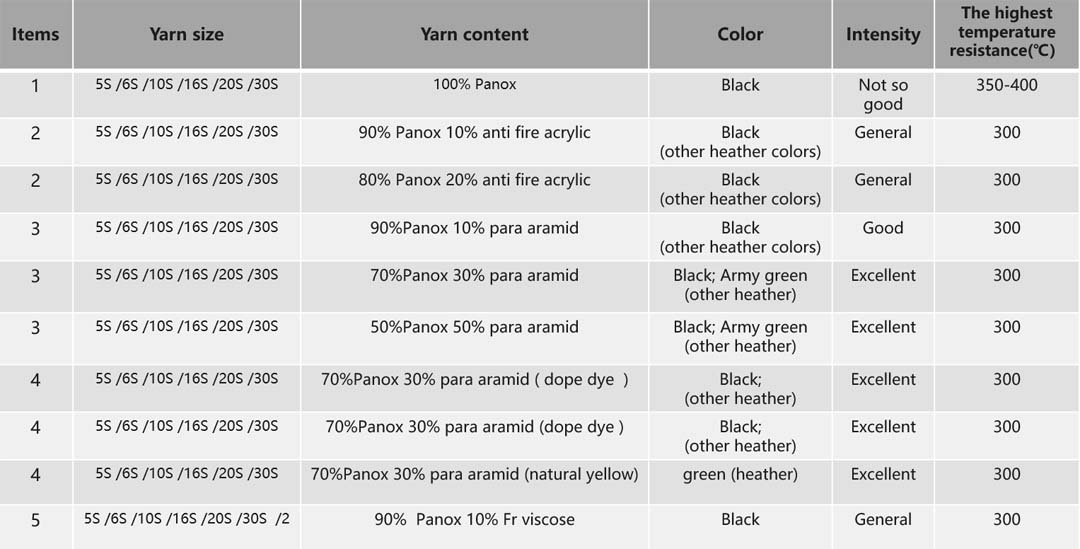

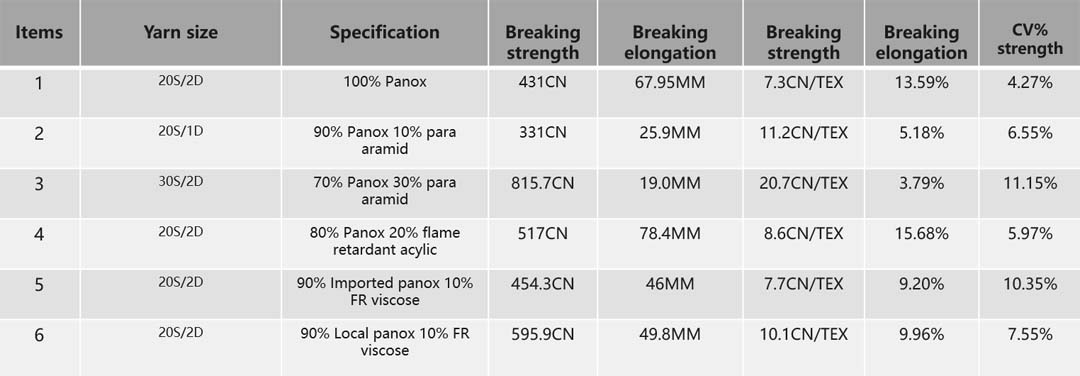

Similar Series Technical Data

Similar Yarn List