-

-

20S2 - 80% Oxidized PAN 20% Flame retardant acrylic - Flame Retardant - Anti-Fire - OX Yarn

- Code:TC-BPY202

- Material:80% Oxidized Pan Fiber 20% Flame retardant acrylic

- Weight:1kg/cone

- Function:High Temperature Resistant, Heat Insulation, Flame Retardant, Fire Retardant

- Color:Black

- Weave:spun

- Count:20S/2

SEND INQUIRY

Material: |

80% Oxidized Pan Fiber 20% Flame retardant acrylic | Yarn Count: | 20S2 |

| Retardant type: | Raw Fiber Flame Retardant | Weight : | 1kg/cone |

|

Spinning process: |

Ring spinning | LOI: | >40% |

Material: |

80% Oxidized Pan Fiber 20% Flame retardant acrylic |

| Retardant type: | Raw Fiber Flame Retardant |

|

Spinning process: |

Ring spinning |

| Yarn Count: | 20S2 |

| Weight : | 1kg/cone |

| LOI: | >40% |

Product Description

20S2 yarn blended with 80% pre-oxidized fiber and 20% flame-retardant acrylic has the following advantages:

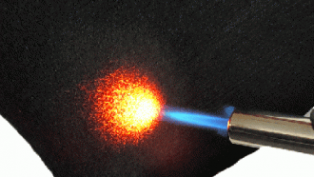

1. Excellent flame retardancy: The limiting oxygen index of pre-oxidized fiber is greater than 45%, and it does not melt, soften, shrink, or drop when burning; flame-retardant acrylic itself has flame retardancy, and the yarn blended with the two has outstanding flame retardancy, which can be used to manufacture products with high fire protection requirements, such as firefighting clothing, fireproof curtains, etc.

2. Good thermal stability: Pre-oxidized fiber has stable performance at high temperatures, and acrylic also has good heat resistance. The blended yarn can maintain good performance under high temperature environment, and can be used in high temperature working environment or products that require insulation.

3. Good strength and wear resistance: The strength of pre-oxidized fiber is relatively low, but the strength of acrylic fiber is high. After blending, the overall strength and wear resistance of the yarn can be improved, making the fabric more durable, which can be used to make protective equipment that requires wear resistance, etc.

4. Comfortable Wearing performance: pre-oxidized fiber fabrics are light, soft, and have good water absorption. Acrylic fiber is soft and elastic. The fabrics made of the blended yarns are comfortable to wear without feeling stuffy, which can improve the wearing experience of protective clothing.

5. Good chemical stability: pre-oxidized fiber is resistant to acid and alkali corrosion and chemical environment. Acrylic also has a certain chemical resistance. The blended yarn can maintain stable performance in a variety of chemical environments and is suitable for protective work clothes in the fields of chemical industry and petroleum.

6. Improved spinnability: pre-oxidized fiber has poor spinnability. After blending with acrylic, the spinnability is improved, and the problems of difficulty in forming, bulky and low strength of yarn, and high breakage rate during spinning are alleviated, which improves production efficiency and yarn quality.

7. Richer color selection: pre-oxidized fiber is generally black, and flame-retardant acrylic fiber has relatively more colors. After blending, the yarn color can be richer to meet different color requirements.

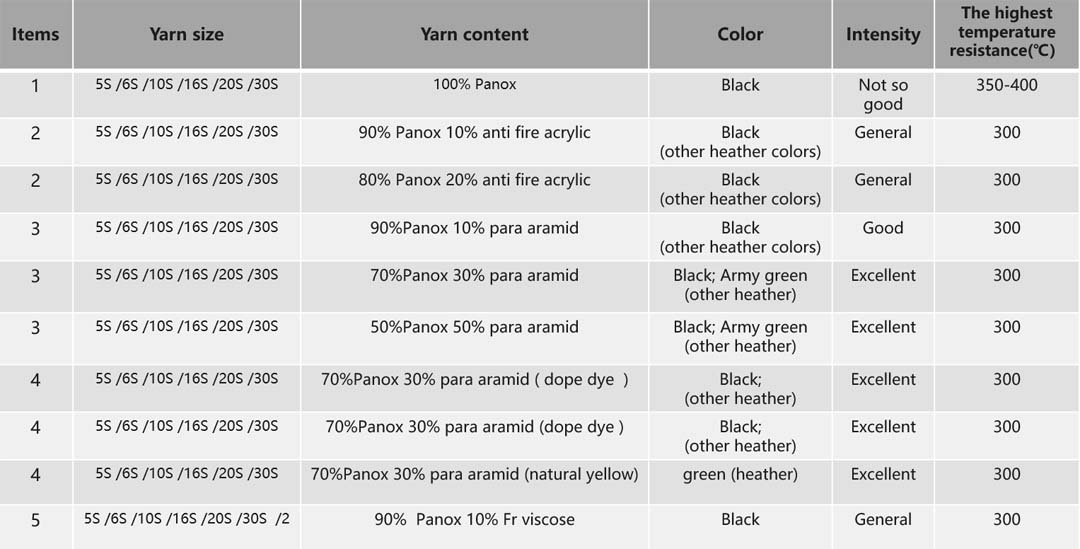

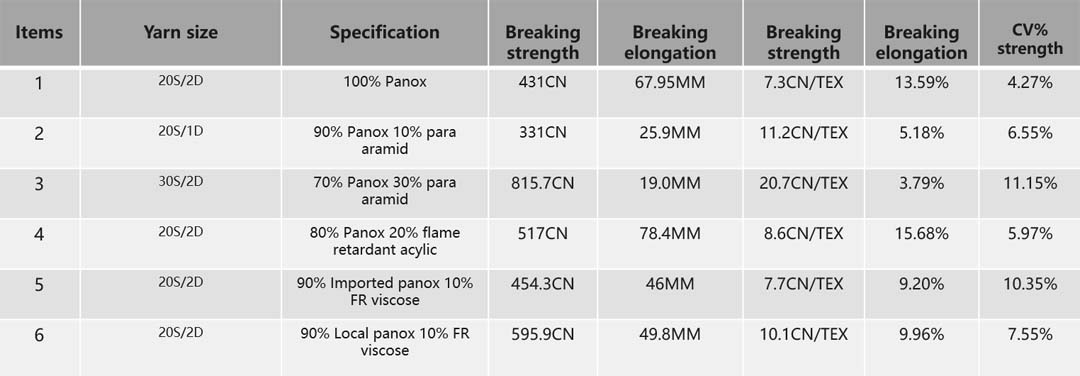

Similar Series Technical Data

Similar Yarn List