-

-

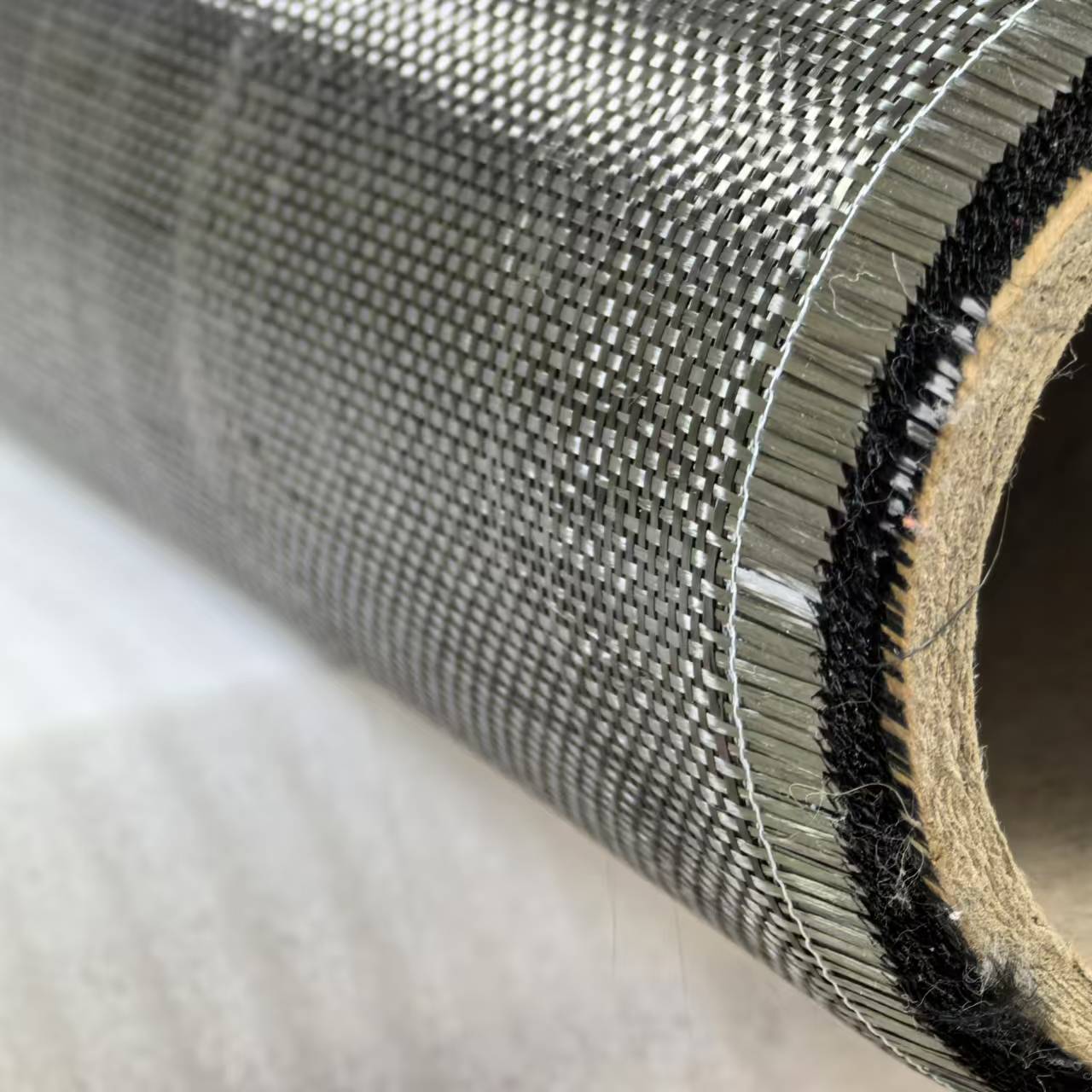

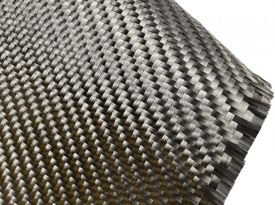

1K Plain Carbon Fabric - 80gsm - 3oz

- Code:TC-CF-1KC080P

- Material:100% Carbon Fabric

- Weight:80GSM

- Function:Aerospace, electronic device, Luxury, micro drones.

- Color:Black

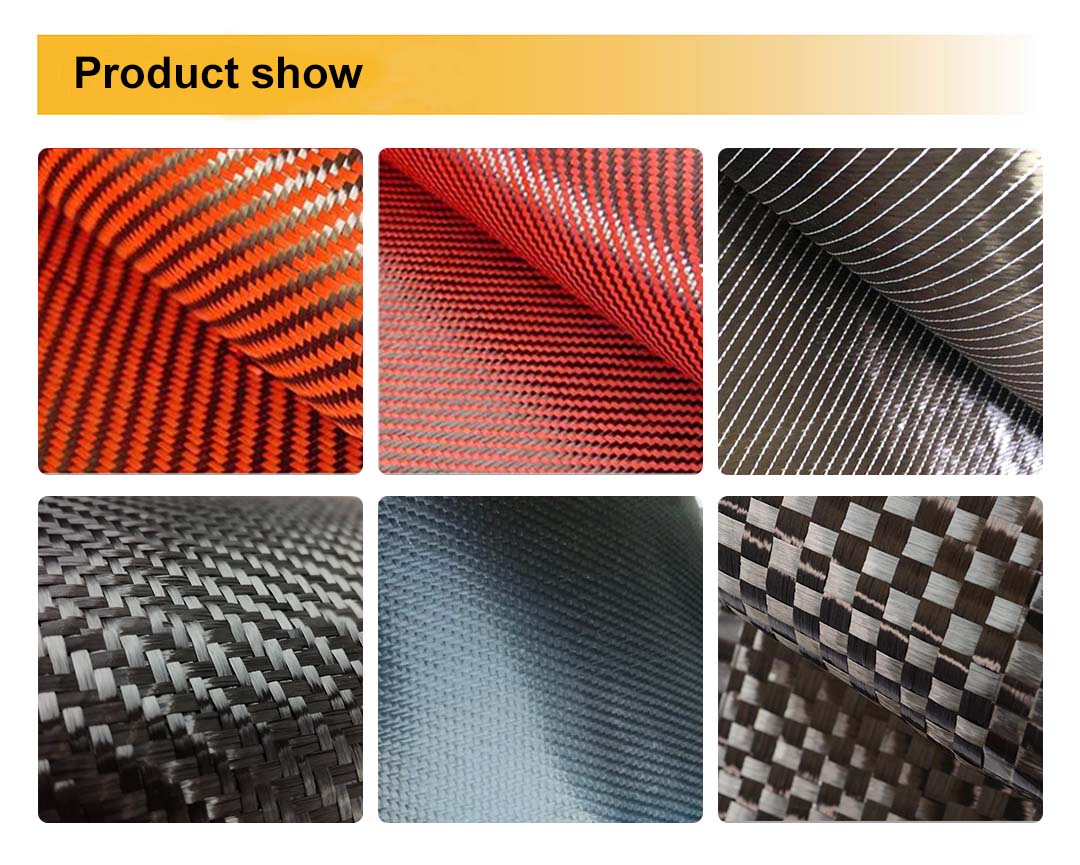

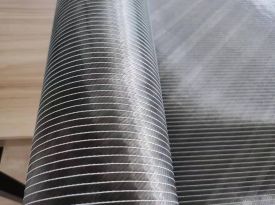

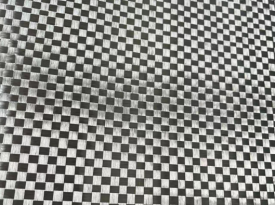

- Weave:Plain

- Width yarn:100cm

SEND INQUIRY

Material: |

100% carbon fiber | Yarn (warp): | 1k carbon fiber |

| Pattern: | Plain | Yarn (weft): | 1k carbon fiber |

| Weight : | 80gsm | Width: | 10-150cm |

| Density(warp): | 6/10cm | Thickness: | 0.12mm |

| Warp tensile strength | >300N/25mm | Weft tensile strength | >240N/25mm |

| Density(weft): | 6/10cm | Color: | Black |

Material: |

100% carbon fiber |

| Pattern: | Plain |

| Weight : | 80gsm |

| Density(warp): | 6/10cm |

| Density(weft): | 6/10cm |

| Yarn Count(warp): | 1k carbon fiber |

| Yarn Count(weft): | 1k carbon fiber |

| Width: | 10-150cm |

| Warp tensile strength | >300N/25mm |

| Weft tensile strength | >240N/25mm |

| Thickness: | 0.12mm |

| Color | Black |

Product Description

1K carbon fiber fabric has the following characteristics:

1. High fineness:

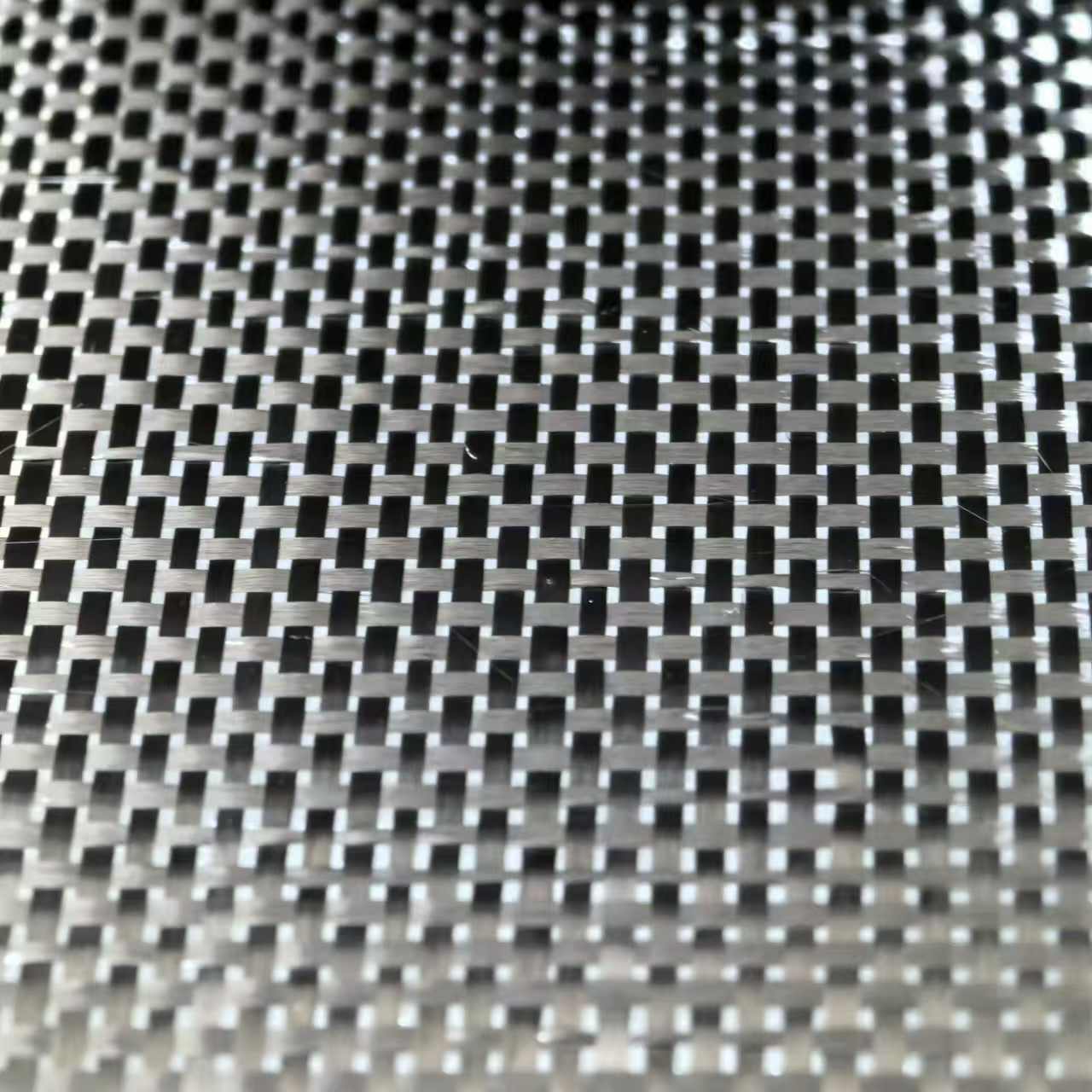

- 1K means that each carbon fiber is composed of 1000 filaments, which is a small-tow carbon fiber fabric. Due to the small number of filaments and finer tows, the woven fabric is finer, the texture is clearer and more uniform, and the appearance is good. This fine feature makes it suitable for products or application scenarios that have high requirements for appearance and need to show high quality and fine craftsmanship.

2. Excellent mechanical properties:

- High strength: Carbon fiber itself has high strength. The tensile strength of 1K carbon fiber fabric is excellent, which is several times or even higher than the tensile strength of steel. It can effectively bear the stress of the structure and can be used to reinforce and enhance the structure to improve the bearing capacity and strength of the structure.

- High modulus: Modulus is an indicator of the material's ability to resist deformation. 1K carbon fiber fabric has a high elastic modulus, which means that the material can maintain good rigidity when subjected to force and is not easy to deform. It is an ideal material for structures or components that need to maintain dimensional stability and precision.

3. Light weight:

The density of carbon fiber is very small, and 1K carbon fiber fabric continues this advantage and is light in weight. Its density is only about one-fourth of that of steel, but its strength is far greater than that of steel. In fields with strict weight requirements, such as aerospace, high-end sports equipment, etc., 1K carbon fiber fabric can provide sufficient strength and rigidity without adding too much weight.

4. Good corrosion resistance:

Carbon fiber has good corrosion resistance and can work stably for a long time in harsh chemical environments such as acid, alkali, and salt. 1K carbon fiber fabric can be used in some occasions with high requirements for material corrosion resistance, such as chemical equipment, marine engineering, etc., which can effectively extend the service life of the structure.

5. High thermal stability:

When not in contact with air and oxidants, carbon fiber can withstand high temperatures above 3000 degrees, and 1K carbon fiber fabric also has high thermal stability. In high temperature environments, its performance will not deteriorate significantly, so it can be used in some high-temperature working occasions, such as aircraft engine peripheral components, high-temperature furnace insulation structures, etc.

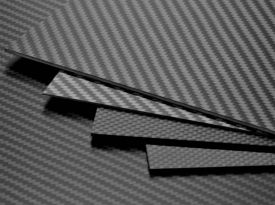

6. Good processability:

1K carbon fiber fabric can be cut, sewn, pasted and processed as needed, and is easy to construct and shape. It can be compounded with materials such as resin to form composite parts of various shapes and structures to meet the needs of different application scenarios.

7. Moderate conductivity:

Carbon fiber has a certain conductivity. The conductivity of 1K carbon fiber fabric can meet some applications that require conductivity, such as electromagnetic shielding, conductive parts of electronic equipment, etc.

80g 1K carbon fiber plain weave has many characteristics and is suitable for the following scenarios:

1. Aerospace:

- Aircraft parts: It can be used to manufacture small structural parts of aircraft, such as aircraft interior panels, small reinforcements on the edge of the wing, etc. Due to its light weight and high strength, it can improve the strength and rigidity of the parts without adding too much weight, which plays an important role in improving the overall performance of the aircraft.

- Satellite structure: In the structure of the satellite, some parts with high requirements for weight and strength can also use 80g 1K carbon fiber plain weave, such as the support structure of solar panels, the antenna bracket of satellites, etc.

2. Sports equipment field:

- Fishing rod: Carbon fiber plain weave is an ideal material for making high-end fishing rods. It is light in weight, which can reduce the burden of anglers, and they will not feel too tired after long-term use; at the same time, it has high strength, can withstand the tension of big fish, and is not easy to break. The specifications of 80g 1K are relatively light and thin, which is suitable for the production of fishing rods with high requirements for weight and feel.

- Golf clubs: It can be used to make the shaft of golf clubs, which can improve the strength and elasticity of the clubs, and improve the power and accuracy of the shots. In addition, the appearance of carbon fiber materials is beautiful, which can increase the added value of the clubs.

- Bicycle parts: For parts such as bicycle frames, handlebars, seat tubes, etc., the use of 80g 1K carbon fiber plain fabric can reduce the weight of the bicycle and improve the speed and comfort of riding. At the same time, the high strength of carbon fiber can ensure the safety and stability of the bicycle during driving.

3. Electronic equipment field:

- Mobile phone cases: Some high-end mobile phone cases are made of carbon fiber materials. 80g 1K carbon fiber plain fabric can provide high-strength protection for mobile phone cases. At the same time, its light and thin characteristics will not increase the weight and thickness of the mobile phone case, and can also show a unique appearance and texture.

- Laptop shell: It is used to make laptop shells, which can improve the computer's resistance to falling and pressure, and protect the internal electronic components. Carbon fiber materials have good heat dissipation performance, which can help laptops dissipate heat better and improve the performance and stability of the computer.

4. Industrial field:

- Mechanical parts: In some mechanical parts with high requirements on weight and strength, such as robot arms, transmission parts of automation equipment, etc., 80g 1K carbon fiber plain fabric can replace traditional metal materials, reduce the weight of parts, and improve the operating efficiency and precision of equipment.

- Mold manufacturing: It can be used to manufacture the reinforced structure of molds, such as the cavity of injection molds, the slider of die-casting molds, etc. The high strength and high rigidity of carbon fiber plain fabric can improve the service life and molding accuracy of molds and reduce the maintenance cost of molds.

5. Automobile field:

- Automobile interior: It is used for decoration and reinforcement of automobile interiors, such as the skeleton of dashboards and seats. The beautiful appearance of carbon fiber plain fabric can improve the grade of automobile interiors; at the same time, its high strength can improve the safety of interior parts.

- Automobile parts: In some high-performance cars or racing cars, 80g 1K carbon fiber plain fabric can be used to manufacture aerodynamic kits, engine hoods and other parts of automobiles, which can reduce the weight of automobiles and improve the performance and fuel economy of automobiles. 6. Construction field:

- Building reinforcement: It can be used to reinforce parts of buildings, such as beams and columns. Carbon fiber plain weave fabric has good bonding properties and tensile strength, and can be closely combined with concrete structures to improve the bearing capacity and earthquake resistance of buildings.

- Building decoration: It is used for building decoration projects, such as making decorative panels for building curtain walls and partitions for interior decoration. The unique appearance and texture of carbon fiber plain weave fabric can add a sense of modernity and technology to buildings.

| Content: | 100% carbon fiber |

| Specification : | 1k-12k, 120-640gsm |

| Color: | Black |

| width: | 10-150cm, customized width is available |

| Feature: | High tensile strength, high modulus, strong durability and corrosion resistance, low thermal expansion, high stiffness, high impact resistance, conductivity, good shock absorption |

| MOQ: | 100m |

| Meet standard : | AATCC/ASTM, EN, ISO, GB, AS |

| Application : | Used in car, trains, transportation, building reinforcement, sports equipment, aerospace, drive shafts, Reinforcement |

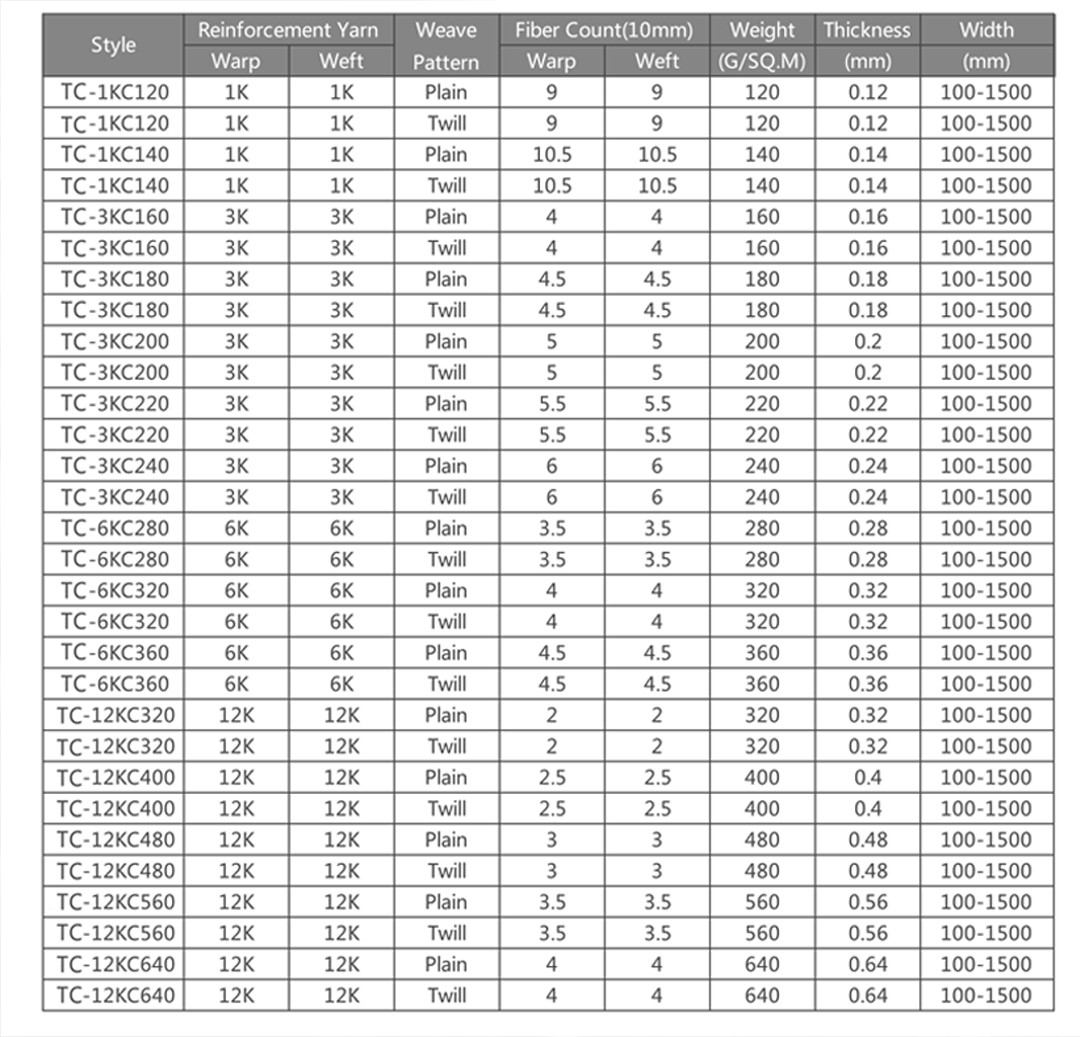

Similar Series Technical Data