Application of Aramid Fiber Cloth in Building Reinforcement

- 2022-11-09

As a new type of engineering structural material, aramid fiber cloth has been proved to be an effective method by a large number of domestic and foreign projects in the field of structural reinforcement. The aramid fiber composite material has the following characteristics: high tensile strength, small specific gravity (about 25% of the steel bar), good corrosion resistance, high elastic modulus, good antimagnetic performance, high shear strength and extrusion strength. Excellent performance .

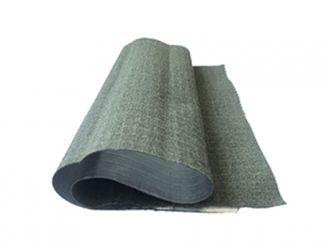

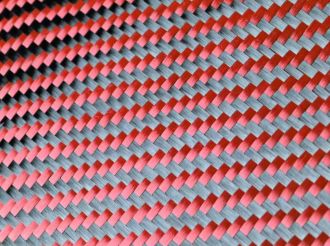

Aramid fiber is a kind of wholly aromatic polyamide fiber, its molecular structure is p-phenylene terephthalamide polymer, which contains both aliphatic main chain and aromatic main chain, so the molecular structure is firm and light. It has many excellent properties such as high strength, corrosion resistance, fatigue resistance, impact resistance, etc., and it is also a non-conductive material. Aramid fabric woven with aramid fibers is a kind of sheet formed by aramid fibers arranged in one direction or two directions. Soft, it is a lightweight high-strength, high-elasticity, corrosion-resistant, non-conductive material, especially aramid fabric has the best fatigue resistance, impact resistance and local load resistance among all FRP composite materials.

At present, common FRP composite materials include carbon fiber (CFRP), aramid fiber (AFRP) and glass fiber (GFRP). At present, the commonly used FRP fiber cloth reinforcement is mainly aramid fiber and carbon fiber. Because the tensile strength and elastic modulus of glass fiber are relatively low, and the texture is relatively brittle, it is generally considered that it is not suitable for use in concrete structure reinforcement projects alone. Due to the good toughness and high elongation of aramid fibers, the failure form in the ultimate state is plastic failure, that is, a large amount of energy is absorbed by its own deformation, which is especially important for seismic reinforcement. Aramid fiber has good toughness and can be made into several shapes of cloth, plate, rib, cable and grid, so aramid fiber has a wider application field than carbon fiber. In addition, aramid fiber is also a non-conductive material. In environments with high requirements for insulation and anti-magnetic properties, aramid fiber has obvious advantages over carbon fiber as a structural material. The construction of aramid fiber is very convenient, and it has very good wettability with the same organic impregnating resin. Due to the good toughness and extension line of aramid fiber under high stress state, it can significantly improve the dynamic load resistance and impact resistance of the structure. In this sense, the application field of carbon fiber is not as good as that of aramid fiber composite materials. It has a wide range. It is suggested that in the design process, attention should be paid to the characteristics of the material, and the best effect can be achieved by applying the appropriate material in the appropriate part.

So what are the advantages of aramid fiber?

1. Impact resistance: The elastic modulus of aramid fiber is 125Gpa, and it has good ductility (elongation rate of 2.4%). Aramid fiber absorbs a lot of energy through deformation first, and its failure form is plastic failure. In contrast, the failure mode of carbon fiber is brittle failure. Therefore, aramid fibers are widely used in aerospace, military equipment, explosion-proof facilities, bridge pier reinforcement, etc.

2. Anti-dynamic load and anti-fatigue performance: carbon fiber has high tensile strength, but the damage form of carbon fiber is brittle failure, which can only withstand long-term static load performance. Aramid fiber has unique advantages in the fields with high requirements on dynamic load resistance and fatigue resistance. Therefore, when carrying out structural reinforcement, attention should be paid to whether to use aramid fiber or carbon fiber for reinforcement according to the characteristics of stress distribution at the structural reinforcement part. At the same time, the shear resistance of aramid fiber is the strongest among all FRP materials, and the use of aramid fiber composite material should be considered when carrying out shear reinforcement.

3. Corrosion resistance: Aramid composite material has good acid resistance and strong alkali corrosion resistance. Chloride ions in seawater are highly corrosive to concrete structures, which can lead to carbonization of concrete and corrosion of steel bars. Therefore, aramid fiber composite materials are commonly used for reinforcement in the structural reinforcement and protection works of some seaport and wharf projects.

4. Non-conductivity and non-magnetization: Aramid fiber is a non-conductive material, so in projects such as precision instrument rooms, hospitals and some special industrial plants, in reinforcement projects that require high insulation Fiber composite materials are more suitable.

5. Construction convenience: The main construction steps of aramid fiber cloth are as follows: concrete surface treatment - brushing primer - bottom layer impregnating resin - pasting aramid cloth - outer layer impregnating resin - outer layer protection. Compared with traditional structural reinforcement techniques such as sticking steel plates and expanding section methods, FRP reinforcement technology has convenient construction, short construction period, and does not require large construction equipment.

The reinforcement technology of aramid fiber cloth for buildings is gradually becoming popular. At present, the commonly used reinforcement methods in China mainly include the following methods of fiber cloth composite material reinforcement, bonding steel plate, external prestressing, and increasing cross-section. The material has distinct characteristics, and because of its obvious advantages in cost performance, it is believed that it will be more and more widely concerned by everyone, becoming the most widely used new technology for the reinforcement of our building structures and other concrete structures, and can be used for aramid fiber for civil engineering in my country. The fiber composite material industry has created conditions for intervening in international competition, with significant social and economic benefits.