-

-

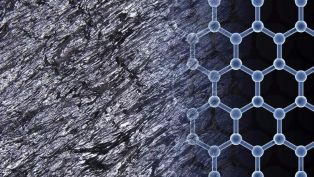

Vacuum Insulation Panel (VIP) -Thermal insulation

- Code:TC-VIP-001

- Material:100% Fiberglass

- Weight:400gsm

- Function:Chemical-Resistant, Flame Retardant, Heat-Insulation, soundproof

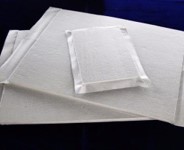

- Color:White

- Weave:Needle-Punched

SEND INQUIRY

Product Properties

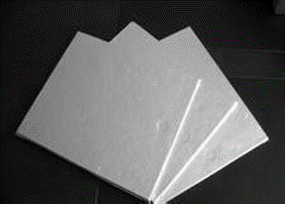

Lightweight, thin and thermal insulation: The thermal insulation performance of VIP vacuum insulation panels is 10 times that of traditional thermal insulation materials of the same thickness (represented by polyurethane foam panels), and is the most advanced and efficient thermal insulation material in current refrigeration and freezing cold insulation materials.

High efficiency and energy saving: VIP vacuum insulation panel products are used in refrigerators and freezers, which can save energy by 20%~30% and increase the effective volume by 20%~30%.

Environmentally friendly and pollution-free: the manufacturing process of the dry-process core material is pollution-free, low energy consumption, and environmentally friendly; at the same time, the diameter of the dry-process core material fiber is 7-11 microns, which meets the EU access standards.

Class A fire protection: Made of 99% inorganic materials, non-toxic and non-irritating, it meets the class A fire protection standard and is non-combustible in case of fire.

Material: |

100% fiberglass |

|

≤0.0015-0.003 |

| Pattern: | Nonwoven | Length: | 200-1800mm |

| Weave: |

Needle-Punched | Width: | 200-800mm |

| Thickness: | 3-45mm (Can be customized) | Roll length: | 100m |

Material: |

100% fiberglass |

| Pattern: | Nonwoven |

| Weave: |

Needle-Punched |

| Thickness: | 3-45mm (Can be customized) |

|

≤0.0015-0.003 |

| Length: | 200-1800mm |

| Width: | 200-800mm |

| Roll length: | 100m |

Product Description

Vacuum Insulation Panel (VIP) for cold chain is the abbreviation of English Vacuum Insulation Panel. It is a kind of vacuum insulation material. It is composed of filling core material and vacuum protection surface layer. The core material is made of thermal insulation material, which has low thermal conductivity. The aluminum foil film and the core material can effectively block heat radiation, and the internal vacuum can effectively avoid heat transfer caused by air convection, so the thermal conductivity can be greatly reduced, and the refrigerated type is less than 0.0025W/ m.K, and does not contain any ODS (Ozone Depleting Substance) material.

Vacuum Insulation Panel (VIP) is the abbreviation of Vacuum Insulation Panel in English. The thermal conductivity can be below 0.002W/(m.K). It is one of the most advanced and efficient thermal insulation materials in the world. In 2019, it was listed as the focus of national strategic emerging industries. products and encourage the development of industries.

In the field of Chinese construction, it is also known as: STP (Super Thin Panel)

| Content: | 100% fiberglass |

| Specification : | Weight, Width, Thickness can be customized |

| Color: | White |

| width: | 200-800mm |

| Feature: | Lightweight, Thin, Thermal insulation, High efficiency, Energy saving, Environmentally friendly |

| MOQ: | 100 Meters |

| Application : | Widely used in cold storage, refrigeration, freezer and other refrigeration equipment fields |

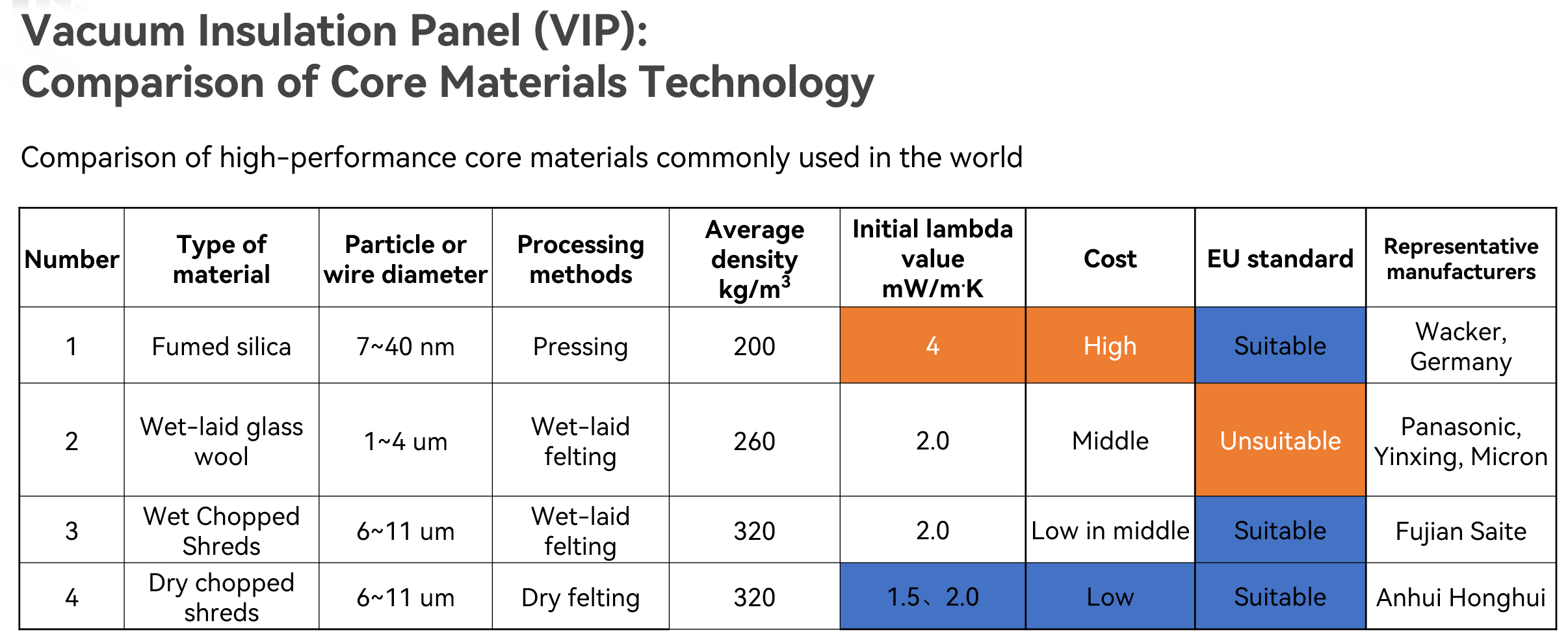

The advantages of technology dry core material:

No pollution, low energy consumption, green environmental protection in the process of waste glass fiber processing and production.

The waste glass fiber does not produce any slag balls in the production process, which ensures the stable performance of the products in the later stage.

The raw materials of waste glass fiber are purchased in large quantities from the cutting materials and leftovers produced by the upstream production enterprises. The cost is cheaper compared to wet-laid glass wool core material and wet-laid chopped strand core material.

The diameter of glass fiber is between 6~11μ, which is suitable for the harmless human body standard in Europe. Compared with the European fumed silica VIP, the cost of the chopped strand VIP is half lower and the thermal conductivity is half lower.

The thermal conductivity of VIP made of wet-processed glass wool core material and wet-processed chopped strand core material is close to the limit, while dry-processed chopped strand core material can continue to drop to a thermal conductivity below 1.5 or even lower.

Application:

VIP vacuum insulation panels have the excellent characteristics of low thermal conductivity and Class A fire rating, and are widely used in refrigeration equipment such as cold storage, refrigeration, freezers, etc., saving space, meeting the fire protection requirements of thermal insulation materials, and reducing construction difficulty.

-

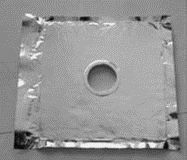

Application of Vacuum Insulation Panel (VIP) in the Field of Refrigerator and Freezer

Due to the extremely low thermal conductivity of the vacuum insulation panel, it can be combined with polyurethane foam and applied to the refrigerator freezer, which can greatly improve the thermal insulation effect and energy saving standards, and can reduce the thickness of the thermal insulation layer and improve the volume ratio of the refrigerator freezer.

-

Application of Vacuum Insulation Panel (VIP) in Cold Chain Field

-

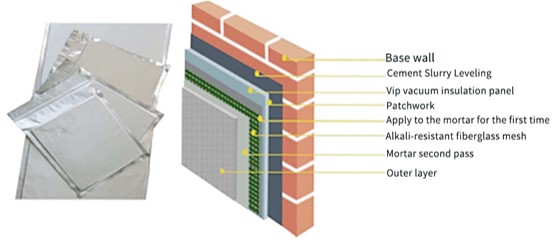

Application of Vacuum Insulation Panel (VIP) in the Field of construction

Vacuum insulation panels have the characteristics of low thermal conductivity and A-level fire rating, and are gradually widely used in the field of building insulation.

Company introduction

Shanghai Tanchain New Material Technology Co., Ltd is a high-tech enterprise focused on developing, producing, and marketing technical textiles products and composite materials, for the industrial, transportation, automotive, and protective industries. We have more than 5 years' experience in producing innovative products for extremely protective and labor protective applications,and with our great advantage in sourcing and technology, Tanchain has grown to be one of the leading suppliers in Chinese technical textiles market. We have a complete industrial chain and a strict quality management system.

Tanchain carefully selected raw material suppliers from dozens of first-class raw material suppliers domestically and overseas, and has signed long-term supply agreements, which ensures that we have large quantities of the best quality raw materials on a timely basis, and it is also a fundamental guarantee of the quality of our company's products.

We have built high-standard modern factories domestically and overseas, and have hired managers and technicians with first-class work experience in domestic and foreign companies, so as to ensure that our products have our own technical advantages and market competitiveness.

Good products allow us to obtain a large number of customers in domestic and overseas markets, and these high-quality customers are our company's valuable resources. Excellent customer groups give us information feedback while improving the function and quality of our products.

The quality control department has been established since the beginning of the company, and the chairman of the company attaches great importance to quality control. We have invested a huge amount of money to ensure the quality of products, which is the basis for our long-term foothold in the market. The factory manages and controls the whole process from raw materials into the factory, production and processing to finished products, and each process follows scientific norms in order for continuous improvement.

Our mission is to be recognized as a premier supplier to the markets we serve by providing quality yarns, fabrics and other textile products to satisfy the needs of our customers. Our mission will be accomplished through excellence in customer service, sales and manufacturing, and supported by teamwork of all associates. We will continue our tradition of honesty, fairness and integrity in the relationships with our customers, associates, community and stakeholders.