-

-

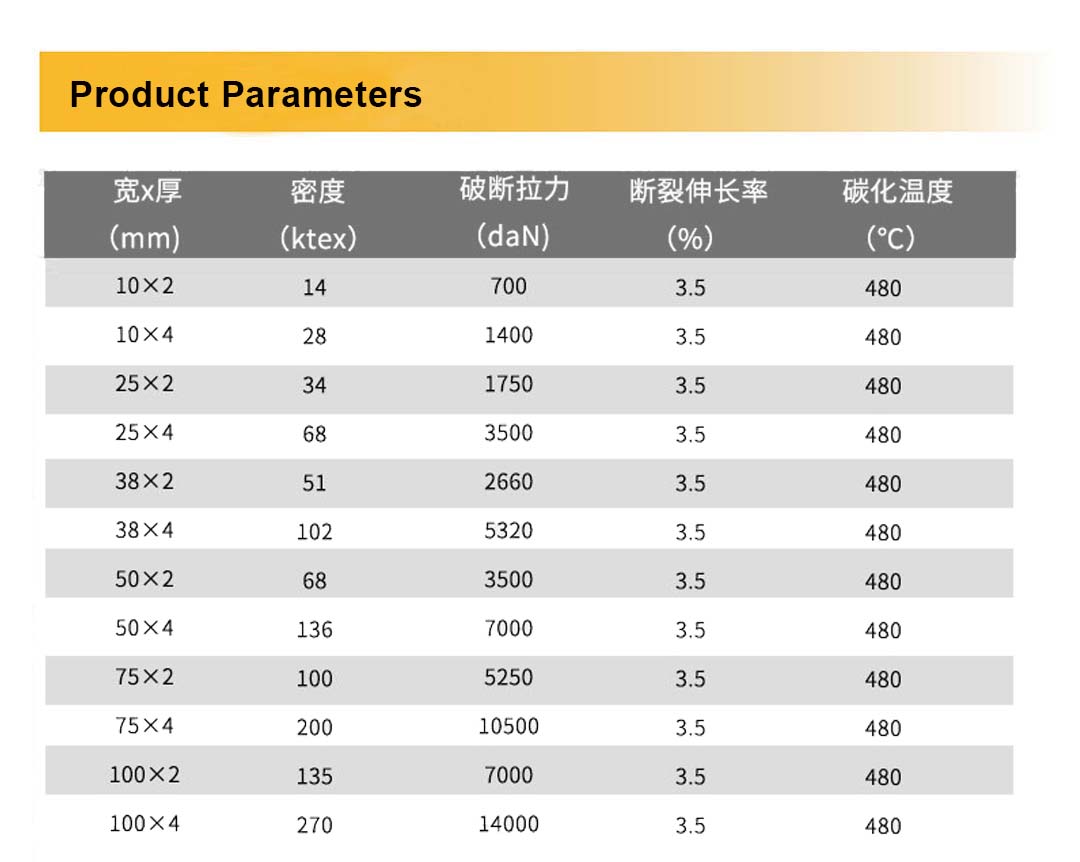

Para aramid tape-Kevlar tape- Fire proof tape-Cut resistant Kevla Tape

- Code:TC-KT-001

- Material:100% Para aramid

- Weight:60GSM

- Function: Fire retardant, High temperature resistance, Wear-resistant And Anti-cutting, Chemical resistance,

- Color: Yellow, Black, Red, Army Green, Orange

- Weave:woven

SEND INQUIRY

Product Properties

Features: light weight, high strength, high modulus, dimensional stability, low shrinkage, puncture resistance, abrasion resistance, heat resistance, chemical corrosion resistance, flame retardancy, good mechanical properties, good dielectric properties, etc.

1. High temperature resistance (fire retardant) Aramid material itself is flame retardant, long-term temperature resistance is about 300°C, short-term temperature resistance is about 700°C, no peculiar smell, no melting droplets.

2. High-strength wear-resistant, light, soft, high-strength, high-modulus, 5-6 times that of high-quality steel and 2 times that of high-strength nylon.

3. Corrosion resistance: The chemical properties are very stable, can resist the erosion of acid and alkali substances, can be used normally in harsh environments, has a long life cycle, and does not require frequent replacement.

4. The insulation is non-conductive, and the current is insulated to avoid electric shock hazards during use.

5. Safe and environmentally friendly, no flame retardants are added, and it meets the testing requirements for environmentally harmful substances. It is a high-performance environmentally friendly fiber material.

Material: |

100% para aramid | Technics: | Woven |

| Pattern: | Twill, Plain | Weight : | 60GSM |

| Width | 5MM-150MM | Thickness: | 0.2MM-5MM Can be Customized |

| Color: | Yellow, Black, Red, Army green, Orange | Packing: | 100M, 200M, 500m/Roll |

| Features: | Fire retardant, High temperature resistance, Wear-resistant And Anti-cutting, Chemical resistance | Applications: | Personal Protective Equipment, Composite Reinforcements, Industrial Applications, Hoisting Traction |

Material: |

100% Para aramid |

| Pattern: | Twill, Plain |

| Technics: | Woven |

| Width: | 5MM-10MM |

| Color: | Yellow, Black, Red, Army green ,Orange |

| Packing: | 100M, 200M, 500M/Roll |

| Features: | Fire retardant, High temperature resistance, Wear-resistant And Anti-cutting, Chemical resistance |

| Applications: | Personal Protective Equipment, Composite Reinforcements, Industrial Applications, Hoisting Traction |

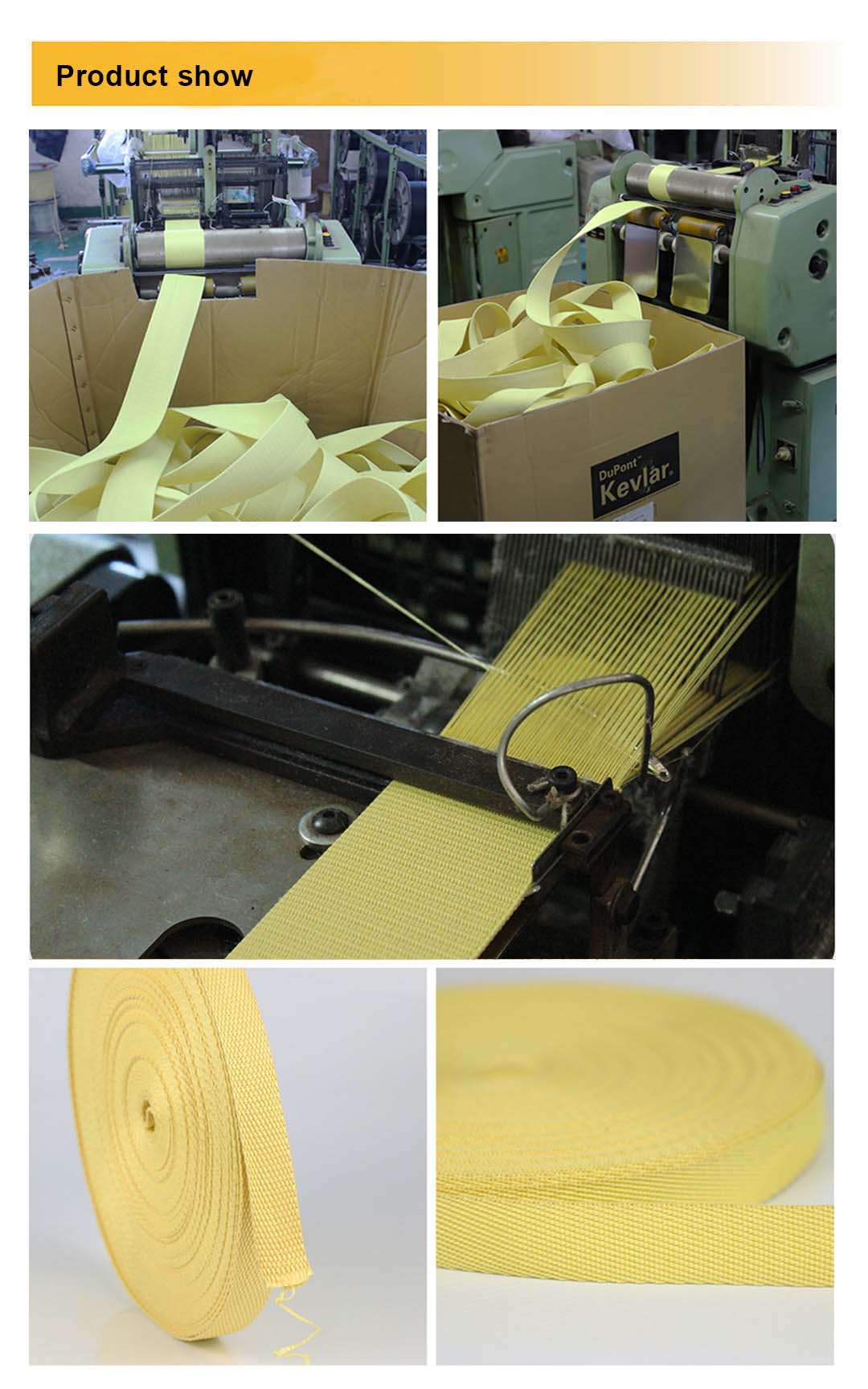

Product Description

Introduction: Aramid webbing is made of aramid 1414 fiber as raw material. It is a new type of composite high-performance webbing. It has extremely high strength (greater than 28 g/denier), which is 5-6 times that of high-quality steel. The modulus is 2-3 times that of steel or glass fiber, the toughness is 2 times that of steel, and the weight is only 1/5 of steel. The continuous use temperature range of aramid is extremely wide, in -196. It can operate normally for a long time in the range of C to 204℃. The shrinkage rate is 0 at 150 °C, it does not decompose or melt at a high temperature of 560 °C, and it has good insulation and corrosion resistance, and has a long life cycle.

Application: Due to the special properties of aramid webbing, it is now widely used in industrial conveyor belts, safety protection belts, industrial hoisting belts, glass tempering furnace roller belts and many other fields with special requirements for webbing.