-

-

200gsm - High Quality - Para aramid fabric - Kevlar fabric - filament fabric

- Code:TC-KF200F

- Material:100% Kevlar Fabric

- Weight:200gsm

- Function:Safty prorection

- Color:Yellow

- Weave:plain weave

- Width:160cm

SEND INQUIRY

Technical Data

Product |

Para aramid fabric for bullet proof |

| Raw material | 1000D para aramid filaments |

Weight |

200gsm |

Width |

1.6m |

Warp density |

9/cm |

Weft density |

9/cm |

Warp breaking Elongation |

5.3% |

Weft breaking Elongation |

5.3% |

200g para-aramid filament fabric has the following characteristics:

1. High strength:

The strength is 5-6 times that of steel wire, which makes the fabric have excellent tensile and tear resistance, and can withstand large external forces without being easily damaged.

2. High modulus:

The modulus is high, that is, the material has a strong ability to resist deformation when subjected to force, which makes the fabric have good dimensional stability and stiffness.

3. High temperature resistance:

It can still maintain good performance in high temperature environment, and the continuous use temperature range is wide. It can generally be used normally between -196℃ and 204℃, and it will not decompose or melt at a high temperature of 560℃.

4. Good flame retardancy:

It is a flame-retardant material, self-extinguishing when away from fire, and no molten droplets will be produced when burning. It can effectively prevent the spread of flames and has good fire resistance.

5. Acid and alkali resistance:

It has strong tolerance to chemical substances such as acids and alkalis, and can still maintain good performance in harsh chemical environments.

6. Light weight:

low density, weight is only about 1/5 of steel wire, which makes the products using this fabric lighter, easy to carry and use.

7. Good insulation:

with good insulation performance, it can be used in electrical insulation and other fields.

8. Anti-aging:

with a long life cycle, excellent anti-aging performance, and can maintain good performance for a long time.

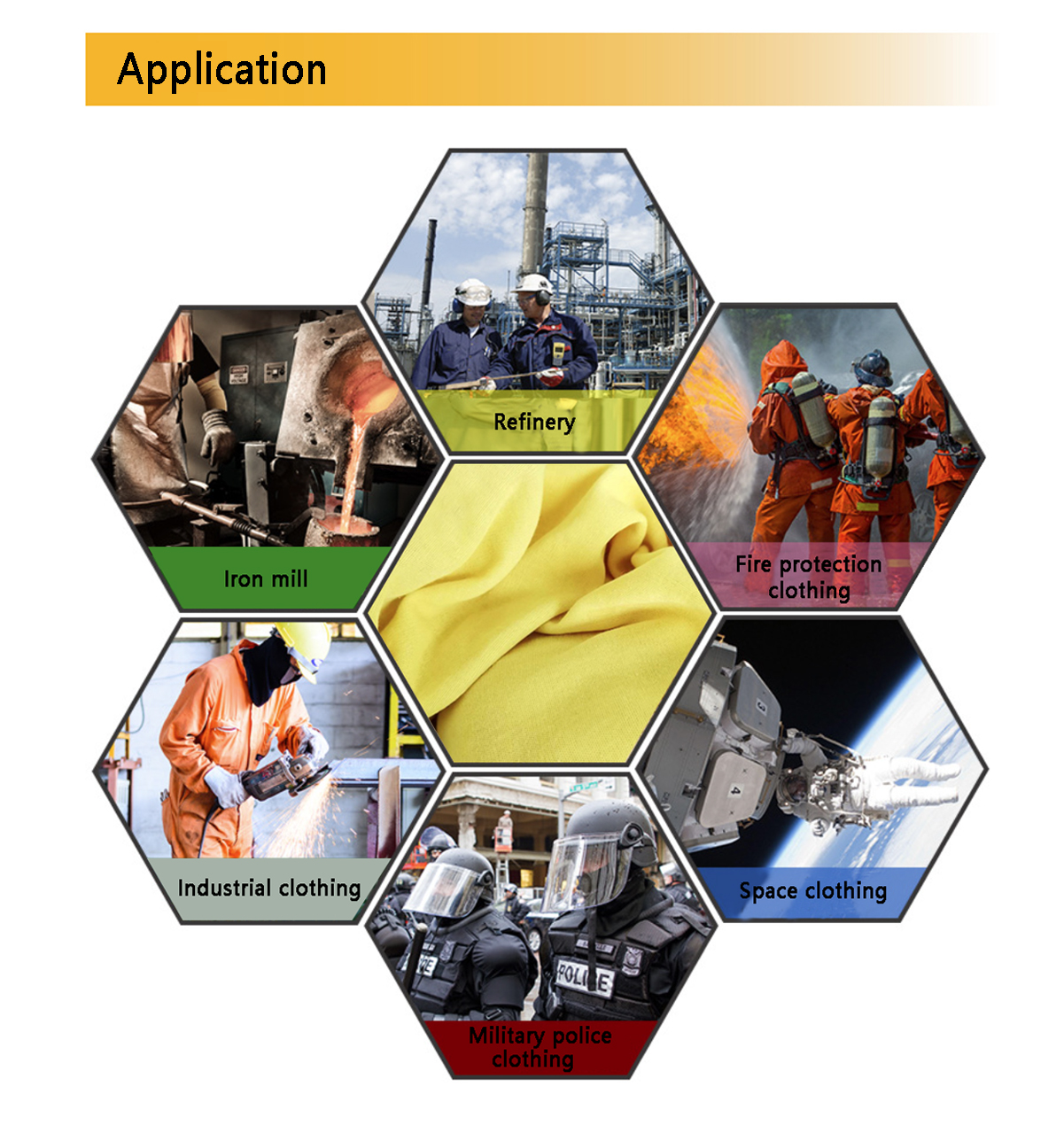

Based on the above characteristics, 200g para-aramid filament fabric has a wide range of uses:

1. Safety protection field:

can be used to make bulletproof vests, bulletproof helmets, cut-resistant gloves, stab-resistant clothing, etc., to provide effective protection for personnel.

2. Aerospace field:

used as reinforcement materials for structural parts such as fuselages, wings, and tails of aircraft and spacecraft, as well as aviation products such as parachutes and seat belts, which can reduce weight and improve structural strength.

3. Military field:

can be used to make military equipment such as military tents, explosion-proof shields, bulletproof armor plates, and can also be used as materials such as military ropes and cables.

4. Automobile field:

It can be used as tire cord of automobiles to improve the wear resistance, cut resistance and puncture resistance of tires; it can also be used for automobile interior materials, brake pads and other parts.

5. Sports goods field:

It is used to make high-end sports equipment such as rackets, fishing rods, skis, racing helmets, etc., which can meet the requirements of equipment in terms of strength, weight and durability.

6. Electronic and electrical field:

It can be used to make printed circuit boards, radar antenna shields, "tension components" of optical fibers, etc., with good electromagnetic wave permeability and insulation performance.

7. High temperature protection field:

It can be used to make fireproof clothing, heat-insulating gloves, high-temperature resistant filter materials, etc., to provide protection for personnel working in high temperature environments.

8. Construction field:

It can be used as a reinforcement material for construction projects to strengthen the structure of buildings and improve the seismic resistance and durability of buildings.

![]()

![]()