-

-

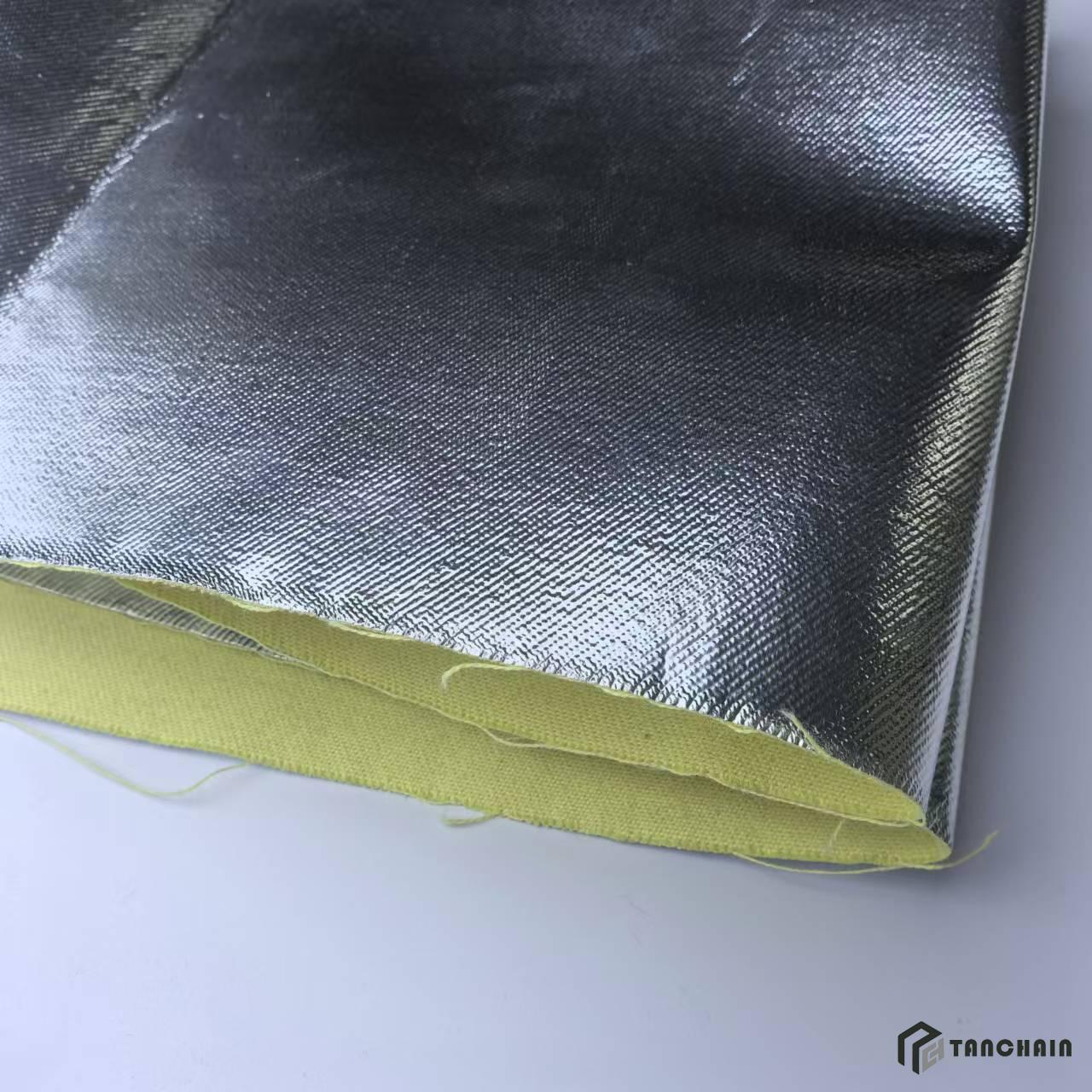

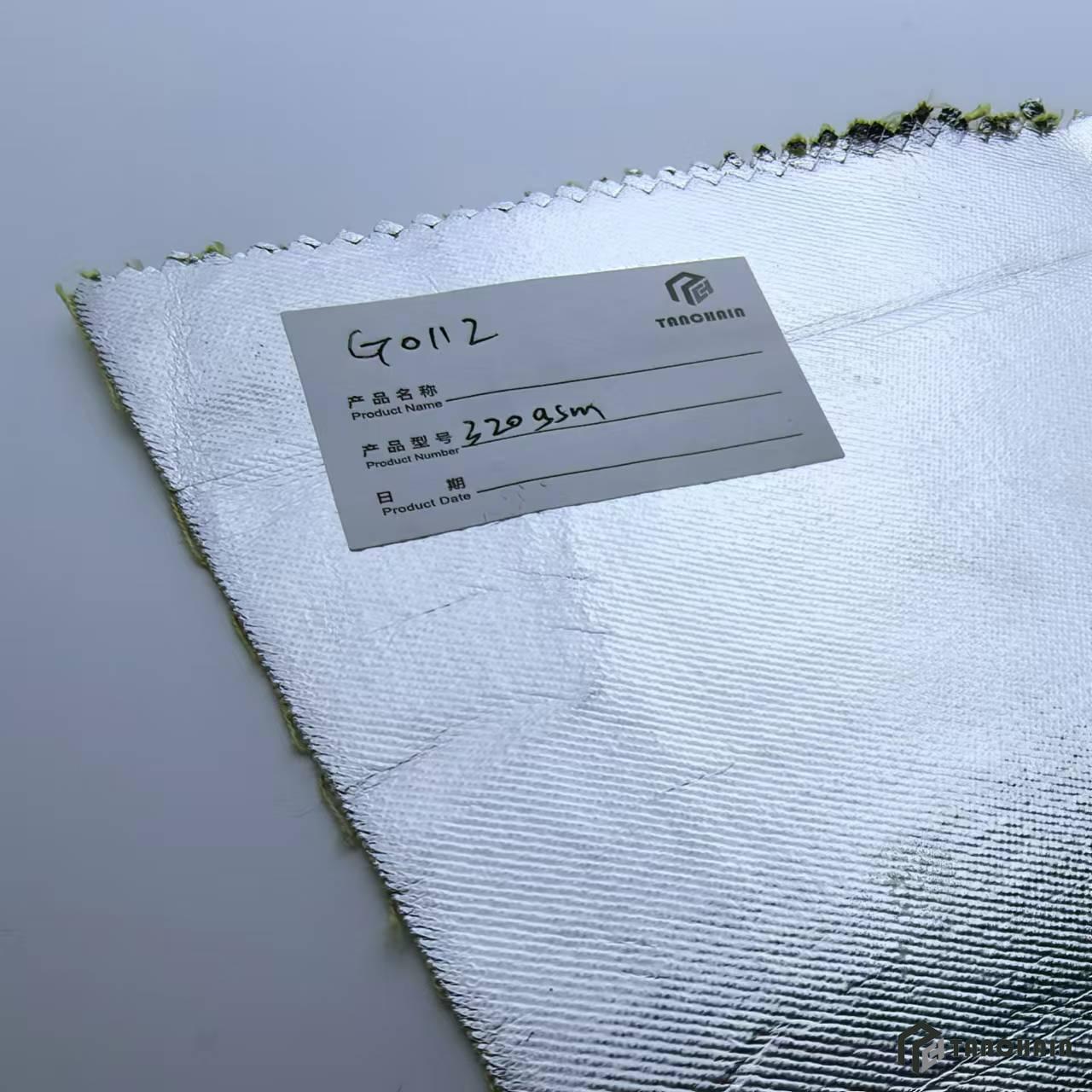

320gsm - Aluminum foil coated para aramid fabric

- Code:TC-KF320AL

- Material:260g kevlar + 60g Aluminum foil

- Weight:320gsm

- Function:Safty prorection

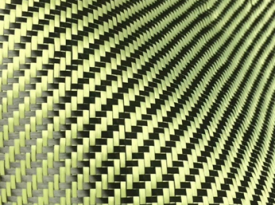

- Color:Yellow

SEND INQUIRY

Technical Data

Product |

Aluminum foil coated aramid fabric |

| Composition | 260g kevlar + 60g Aluminum foil |

Weight |

320gsm |

Width |

1.5m |

Temperature resistant |

-200℃ to 250℃ |

320g aluminum foil-plated Kevlar fabric has the following characteristics:

1. High strength:

Kevlar fiber itself has extremely high strength, which is several times that of high-quality steel. This characteristic makes the fabric have excellent tensile and tear resistance, and can withstand large external forces without being easily damaged. After aluminum foil plating, the overall strength remains at a high level, which can meet the needs of a variety of high-strength usage scenarios.

2. High temperature resistance:

Kevlar fiber has good high temperature resistance and can maintain performance stability at high temperatures. After aluminum foil plating, the aluminum foil layer can reflect heat, further improving the thermal insulation and high temperature resistance of the fabric, which can effectively block the transfer of heat and protect users from high temperature damage.

3. Good flame retardancy:

Kevlar is a permanent flame retardant fiber. It will not continue to burn when leaving the flame, and will not produce melting, dripping, etc. when burning, and will not produce toxic gases, and is highly safe. After aluminum foil plating, the flame retardant performance is enhanced, which can better meet the application scenarios with high requirements for flame retardant performance.

4. Chemical corrosion resistance:

It has excellent resistance to most chemical substances, and can resist corrosion from a variety of chemical substances such as acids and alkalis. It can maintain stable performance in harsh chemical environments and is suitable for some working environments that may be exposed to chemical substances.

5. Light weight:

Compared with some other traditional protective materials, such as metals, Kevlar fabric is lighter in weight, and the weight increase after aluminum foil plating is relatively small, which helps to reduce the overall weight of products made of this fabric and improve the convenience of use.

6. Good flexibility and wear resistance:

Kevlar fiber has a certain flexibility, which allows the fabric to adapt to different shapes and movement requirements during use. At the same time, the fabric has good wear resistance, can withstand long-term use and friction, and is durable.

7. Electromagnetic shielding:

The aluminum plating layer can provide a certain electromagnetic shielding function, which can effectively reduce or block the interference of electromagnetic waves, and has application value in some occasions where electromagnetic shielding is required, such as electronic equipment manufacturing, communications and other fields.

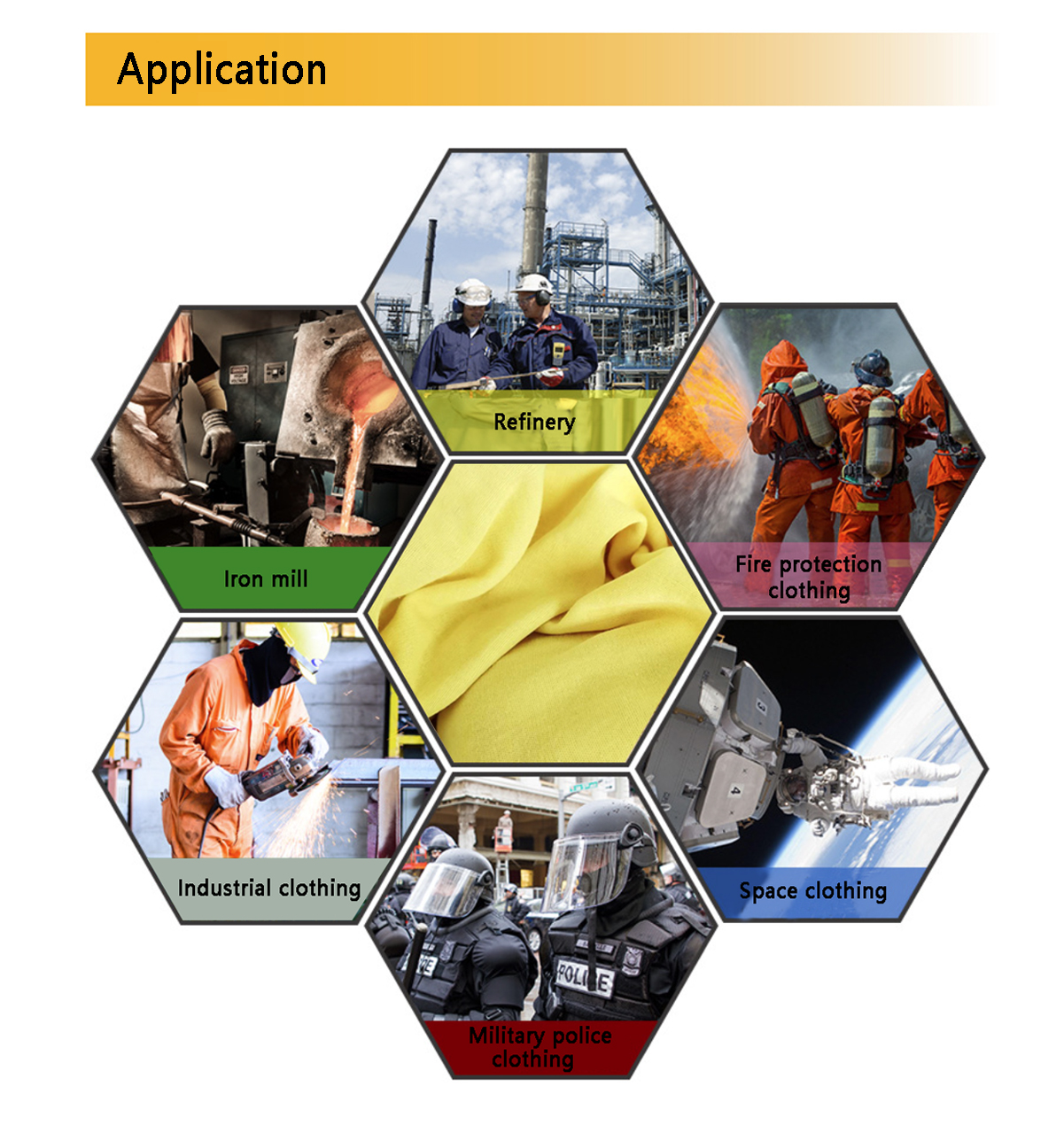

320g aluminum foil Kevlar fabric has a wide range of uses, including:

1. Protective clothing:

It can be used to make special protective clothing such as fire suits, heat insulation suits, flame retardant anti-static work clothes, anti-cutting suits, bulletproof vests, etc. Provide safety protection for firefighters, high-temperature workers, soldiers, etc., so that they are protected from high temperature, flames, cutting, etc. in dangerous environments.

2. Industrial field:

Applicable to petrochemical, metal smelting, glass manufacturing, cement production, ceramic processing and other industries. It can be used to make high-temperature resistant conveyor belts, sealing materials, insulation pads, etc., used to transport high-temperature materials, seal high-temperature pipes and equipment, prevent heat loss, etc.

3. Aerospace field:

In the interior of aircraft and spacecraft, it can be used to make seat covers, carpets, etc., to meet the high-performance requirements of aerospace for materials; at the same time, it is also used in the protection of some key components, such as heat insulation materials around the engine, cable protection, etc.

4. Electronic and electrical field:

Due to its electromagnetic shielding performance, it can be used to make the shell of electronic equipment, the shielding layer of cables, etc., to reduce the impact of electromagnetic interference on electronic equipment.

5. Sporting goods field:

It can be used to make high-performance sports equipment, such as racing suits, mountaineering suits, ski suits, etc., to provide athletes with safety protection and comfortable wearing experience.

![]()

![]()