The new high temperature resistant and flame retardant pre-oxidized blended yarn

- 2022-04-22

At present, flame retardant fibers are generally divided into ordinary flame retardant and high temperature flame retardant fibers. Common flame retardant fibers include: flame retardant viscose, acrylic vinyl, melamine fiber, flame retardant polyester, vinyl chloride, flame retardant cotton, wool, etc.; high temperature resistant fibers include: meta-aramid, para-aramid, polyester Sulfonamide, polyamideimide fiber, pre-oxidized fiber, polybenzimidazole, polyparaphenylene bisoxazole, basalt fiber, ceramic fiber, etc. Among the high temperature resistant fibers, meta-aramid, para-aramid, polysulfone-based amide, polyamideimide and other fibers have high tensile strength, and can also be called high-strength flame-retardant fibers. Among the high temperature resistant fibers, only pre-oxidized fibers, polybenzimidazoles, polyparaphenylene bisoxazoles, basalt fibers, ceramic fibers and other inorganic fibers can withstand temperatures above 500 °C.

Ordinary flame retardant fibers have poor high temperature resistance

but have good spinnability, good wearability and low price for general flame retardant clothing. Fire-fighting clothing and heat-insulating clothing with higher requirements need to use high-temperature-resistant flame-retardant fibers such as: meta-aramid fiber, para-aramid fiber, polysulfone-based amide, polyamideimide, etc. However, clothing used in environments with molten metal splashing such as welding and smelting puts forward higher requirements for flame retardant materials, which need to be able to withstand high temperatures above 500 °C in a short time. Only pre-oxidized fibers and polystyrene can meet this requirement. imidazole, poly-p-phenylene bisoxazole, and inorganic fibers such as basalt fiber and ceramic fiber. Inorganic fibers such as basalt fibers and ceramic fibers have extremely poor spinnability, are brittle and break easily, are difficult to weave, and are difficult to use in clothing. The high temperature resistance of pre-oxidized fiber can reach 500℃~900℃, good heat insulation, limiting oxygen index 45~60, no melting, no softening, no shrinkage, no melting droplets at high temperature, etc. High temperature fabric material. However, pre-oxidized fibers also have their own defects. Pre-oxidized fibers have poor spinnability, are easily brittle, have low strength, are black in color and cannot be dyed, and have a small range of clothing adaptations.

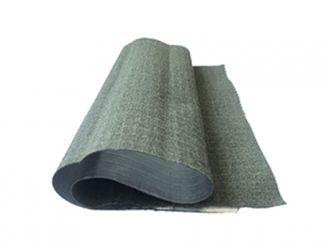

The purpose of the yarn produced by Shanghai Tanchain is to provide a high temperature resistant flame retardant fabric.

The high temperature resistant flame retardant fabric is woven from high temperature resistant flame retardant yarn. High-strength flame-retardant fiber and common flame-retardant fiber are blended; it can also be woven into conductive fiber during weaving. The high-temperature-resistant and flame-retardant fabric of the invention solves the shortcomings of pre-oxidized fibers that are not easy to spin, low in strength, and single black; and has good high-temperature resistance, high strength, good wearing comfort, rich colors and moderate price, and is an ideal high temperature resistant fabric. Flame retardant fabric.

The high temperature resistant flame retardant fabric is woven from high temperature resistant flame retardant yarn, and the high temperature resistant flame retardant yarn is blended with pre-oxidized fiber and high-strength flame-retardant fiber. The weight ratio of the strong flame-retardant fibers is 40-80: 20-60; the square meter mass of the high-temperature-resistant flame-retardant fabric is 150-600 g/m2; the high-strength flame-retardant fibers are meta-aramid fibers, One or at least two of para-aramid fibers, polysulfone-based amide fibers, polyamide-imide fibers, and poly-p-phenylene bisoxazole fibers.

The high temperature resistant flame retardant fabric is woven from high temperature resistant flame retardant yarn, and the high temperature resistant flame retardant yarn is blended with pre-oxidized fibers, high-strength flame retardant fibers, and common flame retardant fibers. The weight ratio of pre-oxidized fiber, high-strength flame-retardant fiber, and common flame-retardant fiber is 40-80: 5-60: 5-40;

The amount is 150 ~ 600g/m2.