The first of new materials is aerogel

- 2022-06-23

Introduction to Aerogels

Aerogel is a highly dispersed solid material in which colloidal particles coalesce with each other to form a nanoporous network structure, and the pores are filled with gaseous dispersion medium. It has the characteristics of low thermal conductivity, low density, low dielectric constant, low acoustic impedance, high porosity, high specific surface area, etc. It shows excellent performance in the fields of heat, electricity, acoustics, mechanics, optics, etc. Transportation, petroleum, communication, central heating and cooling, construction, metallurgy, electronics, environmental protection and other fields have broad and huge application prospects.

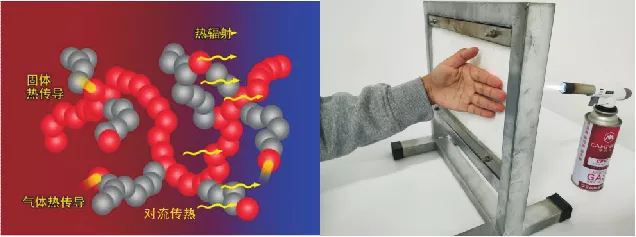

SiO2 Aerogels is by far the best thermal insulation material that has been commercially produced. SiO2 gel material has the characteristics of low density and low thermal conductivity, which can effectively inhibit heat conduction; its average pore size is 50 nm, which is lower than the mean free path of air molecules, which can effectively inhibit air heat convection heat transfer; in addition, SiO2 gel " Infinite" void walls are equivalent to the reflection and refraction surfaces of radiation, and with special reflective materials, thermal radiation can be minimized. To sum up, SiO2 gel material can effectively inhibit the joint effect of heat conduction, heat convection and heat radiation, and block almost all the ways of heat transfer. It is a thermal insulation material with great application value.

SiO2 aerogel performance advantages

-

Thermal insulation:

The thermal conductivity at room temperature is 0.02W/(m·K), and the thermal insulation performance is 3~5 times that of traditional thermal insulation materials.

-

Fire and hydrophobic:

It can reach the national A1 non-combustible standard for building materials, and the water repellency rate is N98%.

-

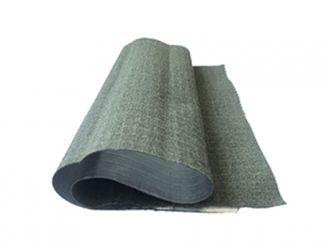

Lightweight and high strength:

Generally, more than 80% of the aerogel is air, the porosity is as high as 80-99.8%, the density of the aerogel body can be as low as 3 kg/m3, and the density of the finished aerogel felt is about 200 kg/m3. tensile and compressive strength.

-

Sound insulation and shock resistance:

The three-dimensional porous network structure of aerogel can play the role of sound absorption, noise reduction and shock absorption.

-

Durable weather resistance:

The overall hydrophobicity of the aerogel insulation material is not easy to absorb hydrolysis, and the service life can reach more than 10 years, which is 3-5 times longer than that of traditional insulation materials.

-

Convenient construction:

It can be processed into shapes suitable for complex parts by using ordinary cutting tools.

-

Safety and anti-corrosion:

Aerogel can effectively prevent the penetration of liquid water, and can effectively prevent corrosion under the insulation layer.

-

Health and environmental protection:

The products have passed RoHS, REACH, ELV testing and do not contain substances harmful to human body.

Aerogel application areas

-

Defense field

Due to the low density, high porosity and low thermal conductivity of SiO2 aerogels, it can meet the needs of thermal insulation applications in this field. Aerogels have been widely used in the field of national defense for a long time: in 1997, American astronauts took the lead in using aerogel as a thermal insulation material on the Mars explorer rover in the aerospace field. in 2008, the National Aeronautics and Astronautics NASA's Kennedy Space Center reported the application of aerogels in the insulation of liquid hydrogen storage tanks for launch vehicles.

-

Oil pipelines

Aerogel felt has the characteristics of high flexibility, low thermal conductivity, good hydrophobicity, easy construction, and durability. Good results.

-

Thermal/chemical pipeline

The advantages of aerogel used in thermal/chemical pipelines are:

Excellent thermal insulation performance, the thickness of the thermal insulation layer is only one-fifth of the traditional material, which can greatly reduce the heat energy loss and reduce the direct burial space of the pipeline.

Good flexibility, tensile and compressive strength, long-term use without disintegration and deformation.

Class A non-combustible material, the material is hydrophobic as a whole.

Thinner insulation layer greatly reduces transportation and installation costs.

Long service life, sustainable use for more than 10 years.

-

New energy vehicles

In the field of new energy batteries, electric vehicle fires and explosions caused by the "thermal runaway" of lithium batteries are frequently reported. By adding aerogel insulation layers between battery packs, heat diffusion can be effectively suppressed in the event of thermal runaway of the battery cells and the occurrence of accidents can be delayed. On the other hand, aerogel has the characteristics of low thermal conductivity, good thermal insulation effect, class A fire resistance, and light weight. Save more valuable space.

-

Industrial kilns

Steam boilers, high-temperature melting furnaces, heating furnaces in the aluminum industry and other industrial furnaces mostly use thermal insulation materials such as aluminum silicate wool, rock wool, glass wool, etc. The thermal conductivity of these materials is mostly higher than 0.15W/(m·K at 500 °C ), poor thermal insulation performance. Aerogel thermal insulation material can reduce the thickness of the furnace wall without losing the thermal insulation effect, increase the effective volume of the furnace body under the condition that the appearance size remains unchanged, and can also optimize the thermal insulation layer of the furnace body. Design to reduce energy consumption.

-

Appliances/Digital

Aerogel is suitable for ovens, ovens, heaters, water heaters and other electrical appliances that require thermal insulation. While achieving the thermal insulation effect, the thickness of the thermal insulation layer is significantly reduced, energy consumption is reduced, and the safety of the operating environment is ensured.

-

Cold chain logistics, ship transportation

The excellent thermal insulation properties of aerogels can be applied to medicine, food cold storage and transportation, cryogenic system devices, etc. Under the same thermal insulation effect, the thickness of the thermal insulation layer can be reduced and the transportation space can be saved. In addition, with the development of ocean transportation and offshore oil fields, the supporting offshore drilling platforms, oil carriers, liquefied natural gas (LNG) ships, and liquefied petroleum gas (LPG) ships have developed rapidly. These special ships put forward higher requirements for thermal insulation and fire separation, and have also become a new application platform for aerogel materials.

-

Construction industry

Aerogel can be used in building exterior wall insulation, interior wall insulation, floor and roof insulation, because of its low thermal conductivity, Class A fire performance, strong hydrophobicity and other characteristics, it can perfectly solve all problems in building insulation; in addition, using Aerogels are used as building insulation materials, which can effectively reduce the thickness of the insulation layer, improve the utilization of housing space, and bring possibilities for safe, low-carbon and energy-saving buildings.

-

Textile industry

Aerogels can be used in jackets, hiking jackets, thermal gloves, thermal shoes and insoles, hats, vests, sleeping bags, tents, yurts, etc. Insulation performance. At the same time, it can be used to make fireproof clothing, fireproof curtains, fireproof blankets, etc., to provide protection for personnel and industrial safety.