Kevlar fiber, carbon fiber and glass fiber each have their own advantages

- 2024-08-20

Advantages and disadvantages of Kevlar (aramid) fiber, carbon fiber and glass fiber

Kevlar fiber, carbon fiber and glass fiber each have their own advantages. Kevlar is high-strength and high-temperature resistant, carbon fiber is lightweight and high-strength, and glass fiber is cheap and easy to process. Comprehensive considerations are required when choosing, and they will play a greater role in more fields in the future.

In the vast field of materials science, reinforced fiber materials play an indispensable role in many industrial and technological fields with their unique physical and chemical properties. Among them, Kevlar (aramid) fiber, carbon fiber and glass fiber, as three common reinforced fiber materials, each has its own unique advantages and limitations. This article will conduct an in-depth comparison and analysis of the characteristics of these three fiber materials, in order to provide more comprehensive and accurate information for professionals in related fields and the public.

1. Kevlar (aramid) fiber

Kevlar fiber, as an aramid composite material developed by DuPont in the United States, has won wide recognition for its excellent performance since its introduction in the 1960s. Kevlar fiber plays an important role in aerospace, military protection, building reinforcement and other fields with its high strength, high modulus, wear resistance, high temperature resistance and good insulation. Its strength is 5 times that of steel fiber at the same weight, and it has a very low density, which gives it a significant advantage in lightweight design. In addition, Kevlar fiber also has good chemical resistance and thermal stability, and can maintain stable performance in extreme environments.

However, Kevlar fiber also has some limitations. First, its price is relatively high, which limits its application to a certain extent. Second, Kevlar fiber has poor UV resistance, and long-term exposure to sunlight will cause its performance to deteriorate. In addition, Kevlar fiber has relatively poor toughness and is prone to breakage when impacted.

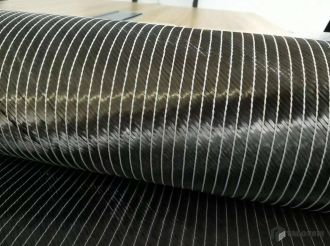

2. Carbon fiber

Carbon fiber, a high-strength and high-modulus fiber with a carbon content of more than 90%, is known for its light weight, high strength, high temperature resistance, and corrosion resistance. Carbon fiber is widely used in aerospace, automobile manufacturing, sports equipment and other fields. Its low density, high specific strength and specific modulus make carbon fiber products have significant advantages in lightweight design. At the same time, carbon fiber also has good thermal conductivity and electrical conductivity, which makes it important for electronic equipment and heat conduction systems.

However, carbon fiber also has some disadvantages. First, the manufacturing cost of carbon fiber is high, which limits its popularity in large-scale applications. Secondly, the toughness of carbon fiber is relatively poor and it is easy to break when impacted. In addition, the conductivity of carbon fiber also brings certain safety hazards, which need to be paid attention to when using it.

3. Glass fiber

As an inorganic non-metallic material, glass fiber is favored for its excellent insulation, heat resistance, corrosion resistance and high mechanical strength. Glass fiber is widely used in construction, aerospace, automobile manufacturing and other fields. Its low price makes glass fiber the preferred reinforcement material in many fields. At the same time, glass fiber also has good processability and weavability, which is convenient for making products of various shapes.

However, glass fiber also has some limitations. First, its strength is relatively low and cannot be compared with Kevlar fiber and carbon fiber. Secondly, glass fiber has poor wear resistance and is easily worn and damaged. In addition, glass fiber is easy to soften and deform at high temperatures, which limits its application in high temperature environments.

In summary, Kevlar fiber, carbon fiber and glass fiber each have their own unique advantages and limitations. When choosing which reinforcing fiber material to use, it is necessary to make comprehensive considerations based on the specific application scenario and needs. In the future, with the continuous development of material science and the advancement of technology, it is believed that these reinforcing fiber materials will play a greater role in more fields.