How do composite materials help achieve decarbonization?

- 2023-10-31

Carbon Neutral Carbon Peak Feature: How Do Composites Help Decarbonize?

Globally, scientists and environmentalists are developing ways to effectively decarbonize, one of which is the use of composite materials.

The term "decarbonization" refers to the process of reducing carbon emission levels by reducing greenhouse gas emissions from industry or reducing the burning of fossil fuels. Simply put, decarbonization is associated with a reduction in the production of carbon dioxide (CO2), especially from transportation and power generation. The increase in the concentration of carbon dioxide in the air is one of the important factors leading to climate change.

Why does the level of CO2 increase?

CO2 is a greenhouse gas that absorbs heat from the sun, and unlike other gases like nitrogen and oxygen, it releases heat gradually over time. Since CO2 is present in large quantities in the air, it causes an imbalance in total energy and an increase in Earth's temperature.

CO2 also dissolves easily in the ocean, where it reacts with water molecules to produce carbonic acid that lowers the ocean's pH. The drop in pH interferes with the ability of marine organisms to extract calcium from the water, which is essential for the development of shells and bones.

Many industries rely heavily on fossil fuels such as coal, oil and natural gas for energy. The burning of fossil fuels leads to the emission of CO2, which contributes to global warming. The researchers believe that the impact of climate change can be reduced if industry changes its energy sources, i.e. from non-renewable to renewable energy sources such as solar, wind, etc.

Composites and Decarburization

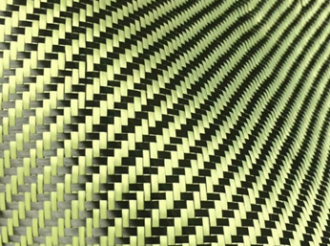

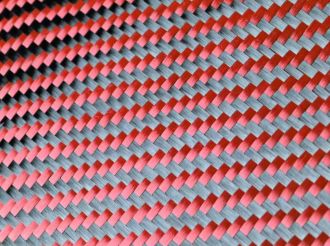

A composite material is a material composed of two or more natural or synthetic materials with different chemical and physical properties. The newly developed composites do not lose the properties of the individual components, but have multiple valuable combinations of properties.

In the aerospace industry, composite materials have been developed and used for a long time. These composite materials help to develop lighter, more durable aircraft structures, which aid in decarbonization. Most of the world is working towards net-zero carbon emissions, and researchers and manufacturers believe that the use of composite materials is an effective way to decarbonize effectively.

Echoing their views, the Composites Leadership Forum (CLF) recently highlighted the role of composites in achieving a future net-zero CO2. Composites are considered the most strategic asset and must be explored to develop products that enhance the green industrial revolution. In 2016, CLF was established to provide independent leadership to the industry. More recently, CLF has focused on developing new composite materials that will help combat climate change.

Development of Decarburization Process for Composite Materials

Composite Braiding is a company founded in 2017 by Steve Barbour. After working in the automotive industry, Barber gained extensive experience and contact with a composites manufacturing company, realizing the importance and need for a lighter composite material that could help decarbonize.

The focus of Composite Braiding is to develop products with a low carbon footprint. The company has built a highly automated production facility that combines materials such as glass, carbon, aramid and basalt fibers with thermoplastics. Newly developed advanced thermoplastics are stronger and stronger than steel and reduce weight by up to 60%.

Furthermore, the thermoplastic matrix used in the manufacturing process is itself recyclable. The newly developed thermoplastic composite can easily reuse heat and pressure and does not require any harmful chemicals. Therefore, this composite material can be easily reused and recycled.

Another advantage of the newly developed thermoplastic composites is that they are mechanically superior, economical and more sustainable than conventional composites. An interesting statistic from the company shows that they produce up to 100,000 parts per year at a cost similar to traditional manufacturing. Another important feature is that the company's manufacturing process reduces waste by up to 95 percent compared to traditional composite manufacturing processes. The reason for the low waste is due to the reuse of leftover materials.

Importantly, when such composite materials are applied to vehicles, namely to develop lightweight and durable frames, seat frames, etc., they can significantly reduce carbon emissions and use less energy. Furthermore, when it is used in infrastructure (such as lighting and communication masts, bridges, etc.), the installation process requires less energy and provides long-term service.

Future development plan

Currently, Composite Braiding is working with the High Value Manufacturing Catapult project established by the UK government and is focusing on creating sustainable composite materials. As part of the Rediscover Composites project, Composite Braiding aims to track recovery, decomposition, recycling and reuse in composites manufacturing.