High performance aramid fiber

- 2023-02-03

Aramid fiber, the full name of "aromatic polyamide fiber", was first developed by DuPont Company in the United States and achieved industrial production. It, carbon fiber, ultra high molecular weight polyethylene fiber and known as the world's three high performance fiber materials.

Aramid fiber, the production process is complex, in the 1990s, the high-performance aramid fiber used in the aerospace field can only rely on imports.

Previously, our country had the ability to produce aramid fibers, but the performance did not reach international first-class level, all produced only some low-end aramid fibers, although they can meet civil needs, but in some special fields can not meet, because the performance is substandard.

After more than 30 years of research by researchers, high-performance aramid fiber fibers are now fully localized. At present, F-12 aramid fiber, independently developed in our country, has a strong tensile and anti-cutting property, belonging to new aramid variety.

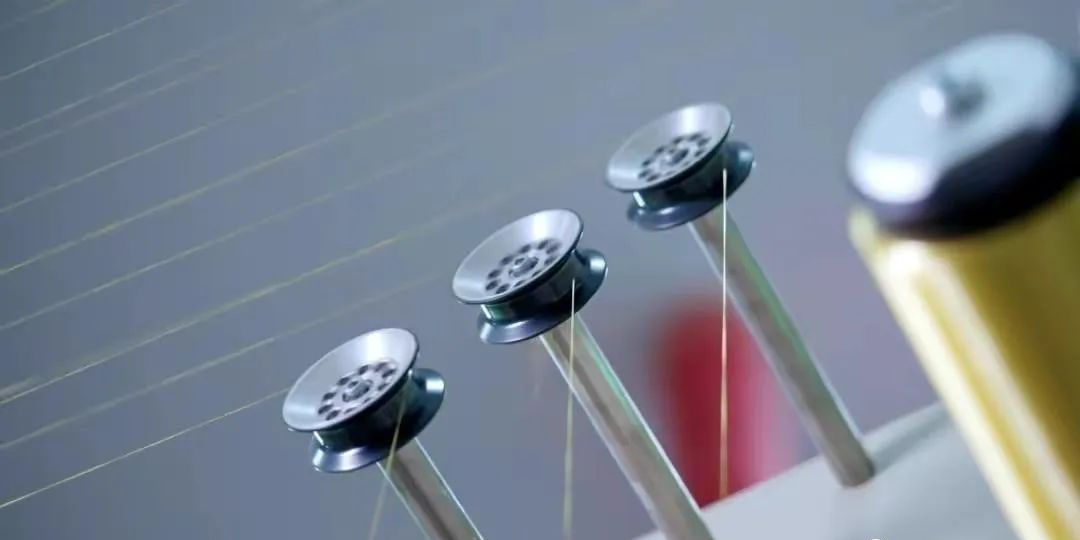

The tiny fibers in this picture, known as aramid fibers, are only 14 microns in diameter, one-sixth the size of a human hair. It is a necessary cutting-edge material in aerospace. The material has high strength and strong toughness, not only strong tensile strength, but also strong anti-cutting performance.

The aramid fiber can pull more than 20 tons when wound into a string with a diameter of 12 millimeters, compared with 8 tons for the same thick steel rope. In other words, just one millimeter of string made of this fiber can pull more than a ton of objects.

In fact, the application of arylon is very wide, aircraft, ships, trains, power facilities of some high-performance structural parts and special electronic equipment manufacturing, as well as building materials, military, sports equipment and other fields are useful to get it.

Aramid fiber varieties of the most practical value are two categories: intermediate aramid (full name "poly (m-benzoyl-m-phenylenediamine), also known as aramid 1313) and para aramid (full name" poly (p-benzoyl-p-phenylenediamine), also known as aramid 1414. The chemical structure of the two is similar, but the properties are very different.

One of the most widely used is aramid 1313, it has excellent high temperature resistance, insulation, flame retardant. In particular, its high temperature resistance is the most outstanding. It will not begin to decompose until the high temperature of 370 degrees Celsius, and it will not begin to carbonize until the high temperature of 400 degrees Celsius.

And aramid 1414 has excellent mechanical properties, making bulletproof, anti-stabbing, anti-cutting and other protective equipment material is it.