Do you know the storage temperature of carbon fiber prepreg?

- 2022-04-22

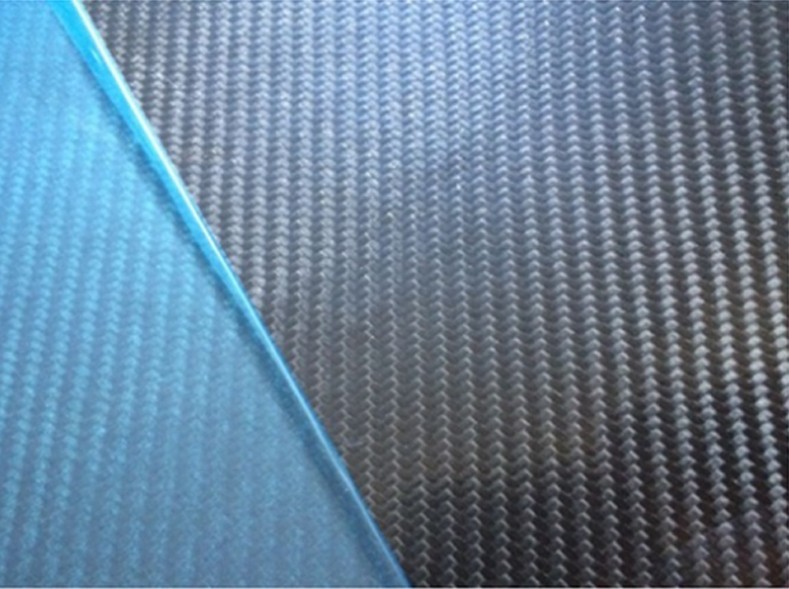

Carbon fiber prepreg is an intermediate material used to make finished products such as plates and pipes. The quality of the prepreg itself determines the quality of the subsequent products. If a company purchases a batch of carbon fiber prepregs and cannot use up all of them in a short time, it is recommended to choose a suitable temperature and environment for storage. So the question is, do you know what the storage temperature of carbon fiber prepreg is?

Carbon fiber prepreg storage and temperature control

Carbon fiber prepreg is an intermediate material formed after carbon fiber tow is infiltrated into a resin matrix, usually a cured prepreg with a lower temperature. Prepreg will have some changes at different temperatures, the higher the temperature, the shorter the reaction curing time. In order to preserve carbon fiber prepreg for a long time, it is necessary to keep it refrigerated during transportation and storage.

Carbon fiber prepreg needs to be stored at low temperature. At room temperature (25°C), the storage period is only 1 month; at -5°C to 0°C, the storage period can be extended to 3 months; if the temperature is lower than -18°C , the storage period can be increased to more than 6 months.

Generally, carbon fiber companies have cold storage to store carbon fiber prepregs. In addition, in the transportation process, vehicles need to be equipped with temperature and humidity recorders. When an enterprise receives prepreg, it needs to receive the data of the recording instrument, check the transportation environment, and evaluate the remaining shelf life of the prepreg, so as to facilitate the designation and implementation of the subsequent production plan.

Carbon fiber prepregs need to be thawed before use

The carbon fiber prepreg should be fully thawed before use to activate the viscosity of the prepreg to achieve a certain process performance. Generally, there are clear requirements and control for the thawing temperature and time. If the temperature is too high, it may damage the service life of the carbon fiber or directly cause the product to solidify and lose its use function. If the temperature is too low, the required performance will be delayed.

The specific thawing method is not complicated. Open the outer packaging box of the prepreg product, fully expose the carbon fiber prepreg to the heating environment, measure the surface temperature of the product regularly during the heating process, and finally raise the temperature of the material to room temperature or process requirements. suitable temperature. Only the thawed carbon fiber prepreg will have a certain viscosity, and the appropriate viscosity is a key factor affecting the laying performance of carbon fiber prepreg.