The Technology Status And Research Progress Of Carbon Fiber In Aerospace

- 2022-04-22

Technical status and research progress of carbon fibers Typical characteristics and applications

Carbon fiber and its applications in the aerospace field.The reason why carbon fiber can be widely used in the aerospace field mainly stems from the following advantages:

(1) Carbon fiber composite materials can meet the high rigidity requirements of spacecraft

As satellites and other spacecraft need to withstand extremely high acceleration overload and severe vibration during launch, the main consideration in the design of satellite structure is to solve the stiffness problem under the condition of meeting the strength. Only by adopting a high-rigidity structure can the satellite structure be ensured. Completeness and functionality. Generally, the unidirectional material of carbon fiber composite material has a modulus 5-7 times larger than that of aluminum alloy. Therefore, high modulus carbon fiber composite material is the best material to meet the structural rigidity requirements of satellites and other spacecraft.

(2) Carbon fiber composite materials can meet the requirements of spacecraft dimensional stability

The main problem of spacecraft operating in the space environment is the high and low temperature alternation. For example, when a satellite is operating in a geostationary orbit, it faces a maximum temperature of 120°C and a minimum temperature of minus 160°C. Satellite structural parts have extremely high requirements for the high-precision and dimensional stability of the structure in the high and low temperature alternating environment. With carbon fiber as the reinforcing material, a composite with nearly zero thermal expansion coefficient can be obtained through a reasonable layer design. Material, so as to meet the spacecraft's dimensional stability requirements in high and low temperature alternating environments.

(3) Carbon fiber composite materials can meet the requirements of lightweight spacecraft

The fuel used by a spacecraft costs about 5 million US dollars per ton. Carrying a large amount of fuel will increase the take-off and flight weight of the spacecraft, and greatly increase the manufacturing cost and flight cost of the spacecraft. It is estimated that for every 1 kg of mass saved by the satellite, the launch vehicle can save 500 kg of fuel and reduce launch costs by US$20,000. Compared with metal materials,Carbon fiber composite materials not only meet the high rigidity and dimensional stability of the spacecraft, but also have a significant lightweight effect, which helps reduce launch and operating costs.

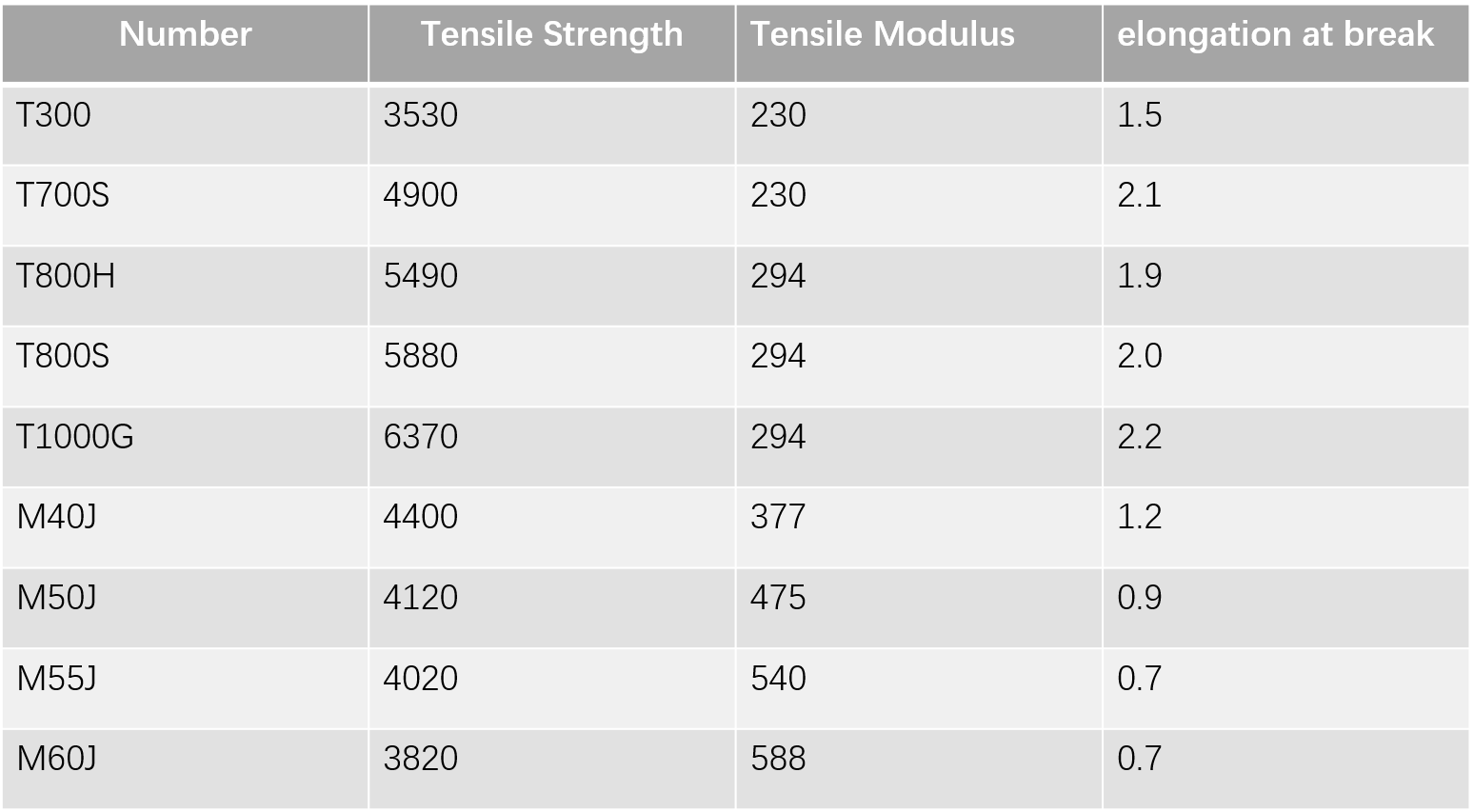

Compared with the above-mentioned excellent performance, Carbon fiber also has certain restrictive factors. The following table shows the mechanical performance indicators of common commercial carbon fibers.

According to the tensile modulus, its carbon fiber products are divided into standard modulus (230 GPa), medium modulus (294 GPa) and high modulus (>350 GPa). It is not difficult to find from the table that, compared with T800H, T800S and other medium modulus carbon fibers, the tensile strength of high modulus carbon fibers is generally lower. For example, the highest strength of M40J grade carbon fiber is only 4400 MPa, resulting in PAN-based high modulus carbon fiber. The elongation at break is less than or equal to 1.2%, which will further reduce the elongation at break and the impact toughness of the high modulus carbon fiber composite material. In recent years, foreign research and breakthroughs in the field of PAN-based high modulus carbon fibers have mostly focused on improving fiber strength and elongation at break.