Application of aerogel in building energy saving

- 2023-01-06

With the improvement of building energy saving requirements and the development of modern technology, building thermal insulation and sound insulation materials are also developing in the direction of light weight, multi-function and green environmental protection. Due to its structural characteristics such as large specific surface area, high porosity, and small particle size, aerogel materials have good thermal insulation performance, fire resistance and flame retardancy, and can effectively meet the energy-saving requirements of modern buildings. At present, its application forms mainly include aerogel glass, aerogel coating, aerogel blanket, aerogel sheet, and roof solar collectors, etc., which have good development prospects and use value in the field of building energy conservation.

01 Application of aerogel in walls and roofs

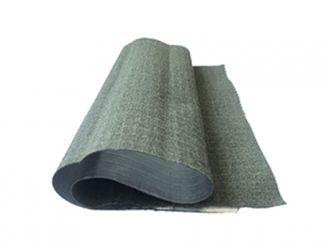

Aerogel felt. Aerogel felt is a thermal insulation felt with certain flexibility made by compounding SiO2 aerogel with fiber reinforced material in the sol stage, and then through the gel and drying process. It solves the problems of low mechanical strength, fragility and cracking of aerogel, and its thermal conductivity is ≤0.022W/m·K. It has good hydrophobicity and aero permeability, and can replace polyurethane foam, asbestos insulation felt, Silicate fibers and other traditional flexible insulation materials that are not environmentally friendly and have poor insulation performance. In order to promote its wide application in the field of building envelope and pipeline insulation, the following problems need to be solved: greatly reducing costs and improving production efficiency; better solving the problem of aerogel powder detachment during use to improve product performance.

Aerogel composite non-combustible insulation board. Aerogel composite non-combustible insulation board is a new type of non-combustible insulation board prepared by composite processing with a special process using a new type of super thermal insulation material aerogel, cement-based gelling material, inorganic composite masterbatch and expandable polystyrene as the main raw materials. , can replace traditional thermal insulation materials, it is an innovative fireproof thermal insulation material in the field of building energy conservation, product density ~100kg/m3, A2 grade non-combustible, thermal conductivity ≤0.042W/m·K, aerogel composite board per unit volume compared with rock wool thermal insulation board, energy consumption is reduced by more than 20%, carbon emissions are reduced by more than 40%, the construction is simple, the bonding strength is twice that of traditional thermal insulation materials, and the comprehensive cost performance and product quality are higher than traditional thermal insulation materials and similar products on the market. It fills a gap in the domestic market and meets the needs of the construction industry for new thermal insulation materials such as safety, environmental protection, high efficiency and energy saving, and has broad market prospects. Aerogel composite non-combustible insulation board is suitable for thin plastering system and thermal insulation and decoration integrated system, and can be widely used in residential buildings, public buildings, industrial plants, combined cold storage, warehouses, warehouse supermarkets, office buildings, renovation of old buildings, activities housing and other fields.

Aerogel vacuum insulation panels. The aerogel vacuum insulation panel is made of nanoporous super insulation material (nano-aerogel, nano-gas phase SiO2) as the core material, added with getter, and wrapped with membrane material. The role of the core material is to ensure the strength of the insulation board, the membrane material is to ensure the vacuum inside it, and the getter is to absorb the gas mixed in the vacuum packaging and the gas infiltrated during long-term use. The reason why the aerogel vacuum insulation panel has excellent thermal insulation performance is that it uses a low thermal conductivity core material on the basis of vacuum insulation to reduce solid heat conduction, and at the same time uses a desiccant and a getter to absorb the gas in the core material. and water vapor to reduce the heat conduction of the gas, and high-performance membrane materials can also reduce heat radiation, thereby fulfilling the requirements of high-efficiency heat preservation and energy saving. Compared with traditional thermal insulation materials (EPS board, rock wool, etc.), its thickness is only 1/4~1/6 of the thickness of traditional thermal insulation materials under the same heat transfer coefficient.

02 Aerogel Thermal Insulation Coatings

Aerogel insulation mid-coat. The main component of aerogel thermal insulation coating is high-performance resin emulsion, with SiO2 aerogel and hollow glass microspheres as raw materials, water as solvent, high-performance thermal insulation material synthesized by special process, and the thermal conductivity can be low To 0.035W/m·K, and Class A fireproof, with sound insulation and noise reduction function, the energy saving effect is obvious. The construction is convenient and the adhesion is strong. When used in combination with traditional insulation boards, the thickness of the insulation layer can be reduced, the weight can be reduced, the fire protection level can be improved, and the service life can be extended.

03 Aerogel Air Purifying Coatings

Due to the large area of paint indoors and the large contact area with the air, it has the inherent advantages of air treatment. Therefore, it has become a trend to produce interior wall paints with the function of removing aldehydes and deodorizing. In the industry, diatomaceous earth is usually added to the paint. , zeolite, calcium silicate and other porous materials, but the aldehyde removal effect is not satisfactory, and the price is expensive. The SiO2 aerogel prepared by the sol-gel method has a porosity of up to 99.8% and a specific surface area of up to 1000m2/g. Combined with the use of a catalyst, it has dual functions of rapid adsorption and catalytic degradation. The prepared coating can be effectively Purify indoor air, antibacterial and anti-mildew, have significant adsorption and degradation capabilities for gas pollutants such as formaldehyde, benzene and hydrogen sulfide, and have excellent anti-bacterial and anti-mildew, formaldehyde degradation, and anti-condensation functions, fundamentally realize the removal of aldehydes and deodorization . It is suitable for homes, offices, and public places, such as high-end hardcover houses, private villas, hospitals, schools, elderly care institutions, and other indoor environments that require air purification.

04 Aerogel Functional Coatings

Aerogel high temperature resistant coating. Aerogel high-temperature-resistant coatings have the characteristics of thin thickness, high temperature resistance, and heat insulation. The thickness of the coating film for construction can be selected according to the use environment and the cooling range to be achieved. It has the advantages of good adaptability and strong controllability. Long-term use in a high-temperature environment above 200°C can protect the substrate, and the physical and chemical properties of the coating can still remain relatively stable. It can be applied to heating pipes inside buildings and other parts that require high-temperature protection.

Aerogel fire retardant coatings. Aerogel fire retardant coating is coated on the surface of flammable substrates, which can effectively prevent heat transfer, reduce the flammability of substrates, delay or even prevent the spread of fire, thereby improving the fire resistance limit of coated substrates. The use of this coating can greatly reduce the damage of building facilities when they encounter fire. The fire prevention effect is much better than that of ordinary fireproof coatings and fireproof materials. It can be applied to many occasions, including the surface of concrete, blocks and steel structures, to protect Safety of buildings, equipment, equipment and personnel.

Aerogel sound insulation and sound absorption coating. Aerogel has a large number of tiny interconnected pores, and sound waves can extend these pores deep into the interior and have friction with them to convert sound energy into heat energy, achieving sound insulation. Generally, it is compounded with other sound-absorbing materials to form a sound-absorbing material with stronger sound-absorbing effect, which can be used in various occasions that require sound insulation and sound absorption, such as households, shopping malls, and hotels.

Aerogel adsorption coating. SiO2 aerogel has a nanoporous network structure and a huge internal surface area, which makes it have the structural characteristics of the adsorption material, and has a super adsorption capacity for organic solvents and organic substances, and its adsorption performance is better than that of common adsorbents (activated carbon) , silica gel, Al2O3, molecular sieves, etc.) are better, and can be combined with other substrates to form new adsorption materials. Aerogel adsorption coating is recyclable, green and economical, and has excellent development potential. It can be widely used in air purification, sewage treatment, water vapor adsorption, medical filtration, seawater desalination and other fields.

05 Aerogel Mortar and Concrete

Adding aerogel with low thermal conductivity to traditional mortar and concrete can effectively improve material performance. Aerogel thermal insulation mortar is made of Portland cement as the gelling agent, adding SiO2 aerogel and glass beads. The size of glass beads is much larger than that of aerogel particles, which can be filled into the mortar matrix, and the smaller aerogel particles further fill the gaps, so that the porosity is reduced as much as possible, and the thermal conductivity of the thermal insulation mortar also decreases. The expected building insulation effect can be obtained. Apply thermal insulation mortar to the surface of the building's exterior wall. The thicker the mortar, the greater the temperature difference between inside and outside. It can be seen that the aerogel thermal insulation mortar can block heat and improve the overall thermal insulation and energy saving effect of the building structure. After adding aerogel to concrete, the weight and thermal conductivity of concrete will be significantly reduced, but it will also damage the mechanical strength of concrete, so aerogel concrete should be avoided in load-bearing walls.

06 Aerogel energy-saving doors and windows

Because the porous network structure of aerogel has "infinite insulation board effect" on heat radiation, it also has sound absorption characteristics and light transmission, so the heat insulation effect of aerogel glass is several times higher than that of ordinary double-layer glass. And has noise reduction effect. Through the extremely low thermal conductivity and thickness of the material itself, aerogel glass can achieve a minimum U value of 0.5W/m2·K, a lighting performance of more than 75%, good sound insulation and noise reduction, and wind pressure resistance, which can significantly reduce hot and cold self-explosion Hidden danger, no condensation, excellent fire prevention and heat absorption performance, thin, light, save other materials, long life, and achieve a balance between building energy saving, comfort and environment. Compared with single glass, insulating glass, Low-E glass, etc., aerogel glass has the most significant thermal insulation performance. Widely used in various energy-saving building projects.

07 Aerogel Solar Collector Gas

The gel material can be used in the thermal insulation device of the solar water heater, so that the utilization efficiency of the solar energy is effectively improved, the utility model is more practical, and can meet people's living needs. The application of aerogel materials in the water storage tanks, heat collectors, pipes and other parts of the water heater can increase the heat collection efficiency by at least 1 times compared with ordinary solar water heaters, and the heat loss can be reduced by less than 30% compared with the past.

Aerogel materials have excellent properties such as heat insulation, heat preservation, and lightweight, which meet the requirements of building energy conservation and the development trend of lightweight buildings. The research and development of composite aerogel materials should be further strengthened, and aerogel materials should be reasonably combined with other materials. , effectively enhance the performance of the material. At the same time, it is necessary to further reduce the cost of aerogel preparation and use in order to occupy a larger share in the construction market and effectively improve the comprehensive benefits of aerogel materials.