-

-

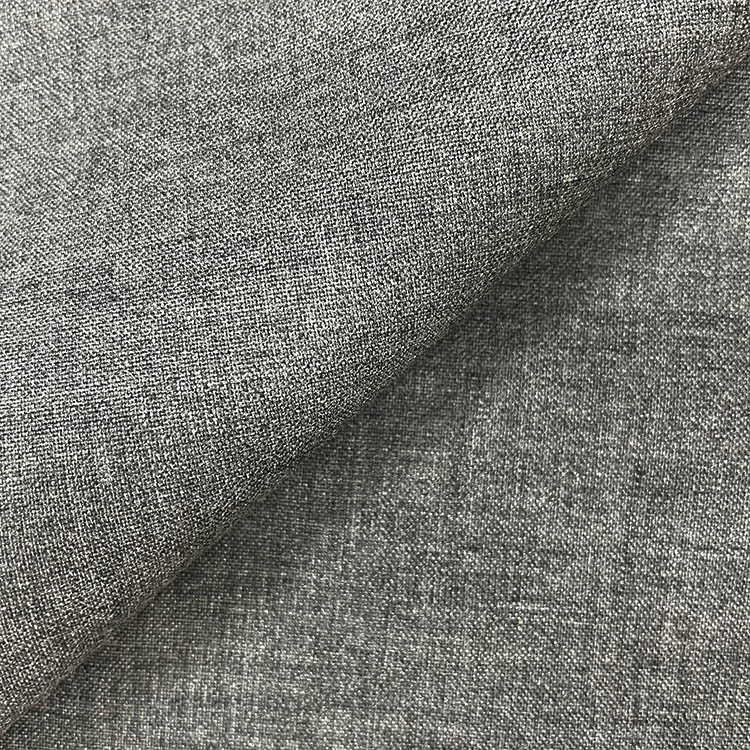

Pre-oxidized polyphenylene sulfide fabric

- Code:TC-BF-001

- Material:Pre-oxidized pan fiber and polyphenylene sulfide fiber

- Weight:380GSM

- Function:Fireproof clothing, Steelmaking clothing, Welder unifrom, Welding blanket

- Color:Black

- Width:150CM

SEND INQUIRY

Product desicription

Pre-oxidized polyphenylene sulfide fabric is blended with polyphenylene sulfide fiber and pre-oxygenated silk. It has good heat resistance and is mainly used as a high-temperature filter fabric with a temperature resistance of up to 190°C. It also has excellent resistance to chemical agents and hydrolysis, as well as flame retardant properties. It can be used as flame retardant fabrics, home decoration fabrics, flue gas filter materials, etc., and can meet the application of fabrics in the field of safety protective clothing.

Polyphenylene sulfide fiber, also known as PPS fiber. It is obtained by melt spinning of polyphenylene sulfide. The American Phillips company was industrialized in 1983 under the trade name of Ryton PPS fiber. The polymer is prepared by polycondensing sodium sulfide and dichlorobenzene in N-methylpyrrolidone or an organic polar solvent containing alkali metal carboxylate, with a melting point of 285°C. Amber color, strength 0.18~0.26N/tex, elongation 25%~35%, initial modulus 2.65~3.53N/tex. It has good heat resistance and is mainly used as a high temperature filter fabric, which can withstand temperatures up to 190°C. The fibers also have excellent resistance to chemical agents and hydrolysis, as well as flame retardant properties. It can be used as flame retardant fabric, home decoration fabric, flue gas filter material, etc.

polyphenylene sulfide fiber performance:

With the continuous emergence of new fiber materials, a new heat-resistant and corrosion-resistant fiber - polyphenylene sulfide fiber has appeared in front of people. Polyphenylene sulfide fiber, also known as poly-p-phenylene sulfide fiber and polyphenylene sulfide fiber, was successfully developed by the Netherlands for the first time.

Polyphenylene sulfide is a crystalline polymer that is usually spun by melt spinning, which is similar to the spinning process of polyester, except that sulfur-containing compounds may be released during the spinning process. The equipment used should be made of special steel, and the spinning system should be sealed and an exhaust device should be installed. The unstretched primary fiber has a large amorphous region, and stretching at high temperature can make the polymer molecules more neatly arranged along the fiber axis direction, and improve the orientation degree of macromolecules. The heat treatment of the drawn fibers at a temperature of 130-230 °C can greatly increase the crystallinity, so that the fibers have better physical and mechanical properties. The stretched fibers are crimped and cut into short fibers.

Polyphenylene sulfide fibers have excellent high temperature resistance. Products made from polyphenylene sulfide fibers are difficult to burn, although they will burn when placed in a flame, but once the flame is removed. Combustion stops immediately, showing low flame retardancy and smoke density. It will not burn under normal atmospheric conditions, and under nitrogen atmosphere, there is basically no molecular cracking below 500 °C. The heat resistance of polyphenylene sulfide fiber is also manifested in: the strength retention rate at 200 ° C is 60%, and it is about 40% at 250 ° C; when it is below 250 ° C, its elongation at break remains basically unchanged; When the multifilament is placed in a high-temperature furnace at 200 °C, the breaking strength remains basically unchanged after 54 days; after 48 hours at 260 °C, 60% of the initial fiber strength can still be maintained.

Polyphenylene sulfide fiber also has outstanding chemical stability, and its corrosion resistance is second only to polytetrafluoroethylene fiber. At high temperature, the original tensile strength can be maintained after being placed in different inorganic reagents for 1 week. Only strong oxidants (such as concentrated nitric acid, concentrated sulfuric acid and chromic acid) can cause the fiber to degrade violently. It also has good resistance to organic reagents. Except that toluene at 93°C has a slight effect on its strength, organic solvents such as carbon tetrachloride and chloroform, as well as formic acid and acetic acid at 93°C have no effect on its strength. The non-woven filter fabric made of polyphenylene sulfide fiber has good corrosion resistance at 93 ℃ and 50% sulfuric acid, and the strength retention rate has no significant effect; placed in 93 ℃ and 10% sodium hydroxide solution for 2 weeks back. There was also no significant change in its strength.

Polyphenylene sulfide fiber has excellent textile processing properties. Its strength and elongation are similar to those of cotton fibers. However, the modulus is lower and the moisture absorption rate is also lower.

Polyphenylene sulfide fiber fabrics can be used in acidic environments and high temperature environments for a long time, and are mainly used as filter materials for hot air or corrosive media, such as filter fabrics in industrial coal-fired boiler bag filter rooms. In the wet acid environment, the service life can reach about 3 years when the contact temperature is 150-200℃. Needle-punched felt belts made of the fibers are ideal for heat- and corrosion-resistant materials for drying in the paper industry. In addition, it can also be used as various canvases, sewing threads, protective cloths, heat-resistant clothing, electrical insulating materials, electrolytic diaphragms under high temperature and corrosive environments, as well as filling and reinforcing materials.

Product Application

It can be used as defogging material, paper machine drying cloth, sewing thread, various protective cloth, electrical insulating material, heat-resistant clothing and other materials. In addition, PPS fibers can be made into long-fiber reinforced composite materials for military, aerospace and other fields. It can be used as flame retardant fabrics, home decoration fabrics, flue gas filter materials, etc., and can meet the application of fabrics in the field of safety protective clothing.

Company Information

Shanghai Tanchain New Material Technology Co., Ltd is a high-tech enterprise focused on developing, producing, and marketing technical textiles products and composite materials, for the industrial, transportation, automotive, and protective industries. We have more than 8 years' experience in producing innovative products for extremely protective and labor protective applications,and with our great advantage in sourcing and technology, Tanchain has grown to be one of the leading suppliers in Chinese technical textiles market. We have a complete industrial chain and a strict quality management system.

Tanchain carefully selected raw material suppliers from dozens of first-class raw material suppliers domestically and overseas, and has signed long-term supply agreements, which ensures that we have large quantities of the best quality raw materials on a timely basis, and it is also a fundamental guarantee of the quality of our company's products.

We have built high-standard modern factories domestically and overseas, and have hired managers and technicians with first-class work experience in domestic and foreign companies, so as to ensure that our products have our own technical advantages and market competitiveness.

Good products allow us to obtain a large number of customers in domestic and overseas markets, and these high-quality customers are our company's valuable resources. Excellent customer groups give us information feedback while improving the function and quality of our products.

The quality control department has been established since the beginning of the company, and the chairman of the company attaches great importance to quality control. We have invested a huge amount of money to ensure the quality of products, which is the basis for our long-term foothold in the market. The factory manages and controls the whole process from raw materials into the factory, production and processing to finished products, and each process follows scientific norms in order for continuous improvement.

Our mission is to be recognized as a premier supplier to the markets we serve by providing quality yarns, fabrics and other textile products to satisfy the needs of our customers. Our mission will be accomplished through excellence in customer service, sales and manufacturing, and supported by teamwork of all associates. We will continue our tradition of honesty, fairness and integrity in the relationships with our customers, associates, community and stakeholders.