Differences Between Meta-aramid and Para-aramid

- 2022-04-22

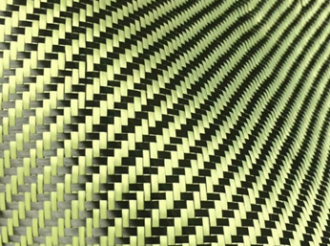

Poly-m-phenylene isophthalamide fiber referred to as meta-aramid; poly-p-phenylene terephthalamide fiber, referred to as para-aramid.

The differences are as follows:

1. The molecular arrangement is different. The meta-aramid fiber has a zigzag arrangement of molecular chains; the para-aramid fiber has a linear molecular chain arrangement.

2. Different production processes. The para-aramid has a complex process and a complicated process due to the complex process of the para-aramid two-step process, and the meta-aramid needs only one step.

3. Different uses. Meta-aramid is widely used as a binder fiber in the manufacture of specialty paper-based materials. Para-aramid fibrid is a new differentiated product of meta-aramid fibrids, which has great potential in the application of high-performance paper-based materials.

The main advantages of using para-aramid fiber products:

Reduce noise, instability and vibration; reduce wear rate; smooth and polish effect; reduce corrosion; increase strength; improve edge stability; prevent cracks in brake pads.

Aramid fiber features:

Aramid fiber has extremely high strength, modulus and toughness, and has excellent insulation performance and high temperature resistance. The length of aramid fiber is mainly determined by the performance of the product, and the specification is 2~80mm or even longer.

The aramid paper-based material prepared from the raw material has the characteristics of high strength and high modulus, light flame retardancy, high temperature resistance, corrosion resistance and excellent insulation performance, and can be used as a high temperature resistant insulating material for electric motors, transformers, reactors and the like. Equipment is an important basic material for promoting the development of the modern power industry.