Carbon Fiber Common Application Products, Excellent characteristics of carbon fiber board

- 2022-04-22

01 Excellent characteristics of carbon fiber board

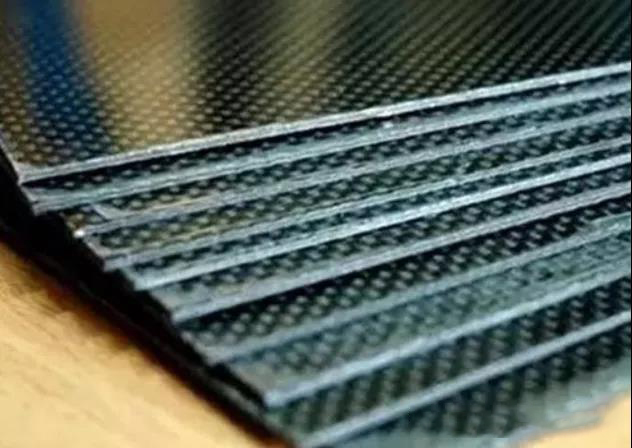

Carbon fiber board is a form of carbon fiber composite product. It is formed by impregnating carbon fiber with resin and then curing it in a mold. Compared with titanium, aluminum or steel, carbon fiber board is usually a better material choice.

Carbon fiber board has high strength, good corrosion resistance, shock resistance and impact resistance: carbon fiber board has excellent physical and mechanical properties, the tensile strength is more than 6 times that of ordinary steel, the elastic modulus is better than steel, and it has excellent creep resistance Variable performance, corrosion resistance and shock resistance.

Carbon fiber board is light in weight and good in flexibility: carbon fiber board has higher strength than steel, and its quality is only 1/5 of steel. It has high toughness, can be coiled, and can be supplied in larger lengths without overlapping.

The construction of carbon fiber board is convenient and the construction quality is easy to guarantee: there is no wet operation, no need for large construction equipment, and no need for on-site fixed facilities. The length of the carbon fiber board can be arbitrarily cut, the construction is simple, and the construction period is short. The material does not need to be pre-processed, the process is convenient, and the plates are allowed to cross.

Good durability and corrosion resistance of carbon fiber board: acid, alkali, salt and atmospheric corrosion resistance, no need for regular maintenance. And it has a protective effect on the internal concrete structure, and can achieve the purpose of double reinforcement and repair.

02 Types of carbon fiber panels

Carbon fiber boards can be divided into the following types according to their structural composition:

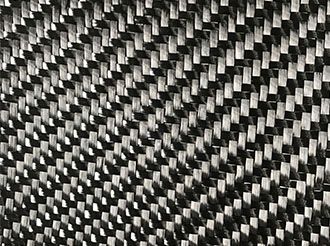

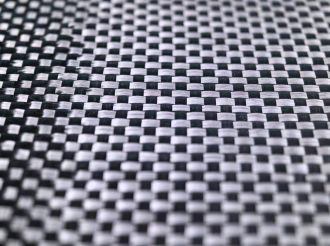

0°/90° Balanced Laminated Carbon Fiber Sheet: Excellent strength and stiffness in both longitudinal and transverse directions. They are textured on one side for easy bonding, while the other side has a choice of gloss, matt or textured finishes.

Quasi-Isotropic Carbon Fiber Sheet: Designed for loading in multiple directions, this 0°/90°/45° fabric is ideal for torsional or off-axis loading due to the extra stiffness in the 45° direction.

Prepreg Carbon Fiber Sheet: Use when maximum strength or weight stiffness is required. These carbon fiber panels are made from unidirectional carbon fiber prepreg and/or twill carbon fiber prepreg. Manufactured in a heat press, these boards provide greater fiber volume, reduced voids and higher temperature performance. Prepreg carbon fiber sheets are available in standard modulus, high modulus and ultra-high modulus.

03 Applications of carbon fiber panels

3.1. Aerospace applications

Carbon fiber sheets are widely used in the aircraft industry. In fact, 30% of all carbon fiber produced is used in the aerospace industry. In addition to reducing the load on the aircraft, it is easier to maintain than metal and other traditional materials.

Another big use of carbon fiber in the aerospace industry is in tool design. Many of the tools used in aircraft production are very large, heavy and unwieldy. Using FEA calculations, in some cases, the weight of these tools can be reduced by as much as 75% when using carbon fiber to make tools.

3.2. Military use

In the field, military equipment often has to be moved over long distances with minimal resources, and reducing equipment weight means reducing energy to move equipment. This equates to saving time, effort and cost. Carbon fiber sheets are used in many military applications, from radar structures to tactical gear to drones for surveillance missions.

3.3. Medical use

Because carbon fiber is X-ray transparent, meaning it is transparent to X-rays and appears black in radiographic images, it is an ideal material for many medical applications. In addition to maintaining critical strength and stiffness under load, carbon fibers do not break even with repeated exposure to X-ray or gamma radiation. This makes carbon fiber sheets ideal for imaging device construction as well as prosthetics, and carbon fiber is even being studied to strengthen damaged cruciate ligaments.

3.4. household carbon fiber board

Carbon fiber is the new fashion in home decoration, and various household products made of carbon fiber sheets can be found on the market today. Carbon fiber furniture is lightweight, durable, easy to clean, and has a high-end, high-tech look. Today, you can also find everything from phone cases and bathtubs to bow ties made of carbon fiber. These applications are limited only by imagination.

3.5. Exhibition panels

Anyone who's worked on a corporate trade show knows that a company booth needs to be lightweight, durable, and look better than everyone else. Once again, carbon fiber panels provided the perfect solution. The booth, made from carbon fiber, has a high-tech look and can withstand the hassle of repeatedly setting up, dismantling and moving from city to city.

Anyone who's worked on a corporate trade show knows that a company booth needs to be lightweight, durable, and look better than everyone else. Once again, carbon fiber panels provided the perfect solution. The booth, made from carbon fiber, has a high- tech look and can withstand the hassle of repeatedly setting up, dismantling and moving from city to city.