Development Of New Analytical Techniques Using UD Unidirectional Band

- 2023-10-31

On January 27, Toray released information through its official website: The company has developed a new analytical technique, mainly for the analysis of multi-material structures consisting of UD tapes (unidirectional continuous fiber reinforced tapes) and injection-molded materials. This breakthrough enables more accurate prediction of the performance of components composed of multiple materials and faster development of high-performance components.

The company hopes to provide UD tapes, injection molding resins and other materials in the future, as well as structural design, molding support and other services, while providing total solutions that incorporate its new technology.

Toray will use this technology to expand the application of its materials in urban air mobility, electric vehicles and other advanced transportation, as well as in the general industrial sector, helping manufacturers create lighter, more energy-efficient products.

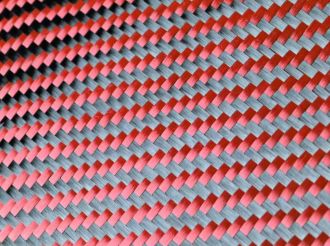

UD tape is a tape-like intermediate substrate, which is prepared by embedding reinforcing fibers such as carbon fibers in thermoplastic resins such as polyamide 6 and polyphenylene sulfide in a unidirectional arrangement. Continuous fibers provide excellent stiffness and strength, and can be welded to other thermoplastics.

Taking advantage of these properties, and optimizing the arrangement of UD tapes in injection molded products, can create multi-material structures that minimize weight while reducing cost. However, multi-material structures also have certain disadvantages. For example, it is difficult to accurately analyze strength and impact properties when laying UD tape on injection-molded products, which are critical for multi-material structures.

Therefore, Toray Corporation set out to develop new analytical techniques to accurately reflect the bond strength between materials and material fracture behavior by employing improved 3D TIMON® technology. The subsidiary Toray Engineering D Solutions Co., Ltd. has developed TIMON, a computer-aided engineering system for 3D injection molding.

In addition, Toray has created a coupled analysis technique for resin flow and impact properties that can affect the fiber orientation of injection-molded materials. This technique combines the analysis of various phenomena and calculates the interactions between them. This work has led to the company's precise new analytical techniques that help accelerate the structural design of multi-material structures. Toray will strive to help reduce weight and energy consumption by deploying this technology in a variety of advanced transportation and general industrial applications.