Application of aramid fiber in conveyor belt

- 2022-12-08

Aramid fiber, also known as aramid fiber, is a type of high-performance synthetic fiber. The "Kevlar" we are familiar with is a kind of aramid fiber. As a high-performance fiber, aramid is widely used in aerospace, military, high-temperature filtration, electric power, electricity, construction and other fields.

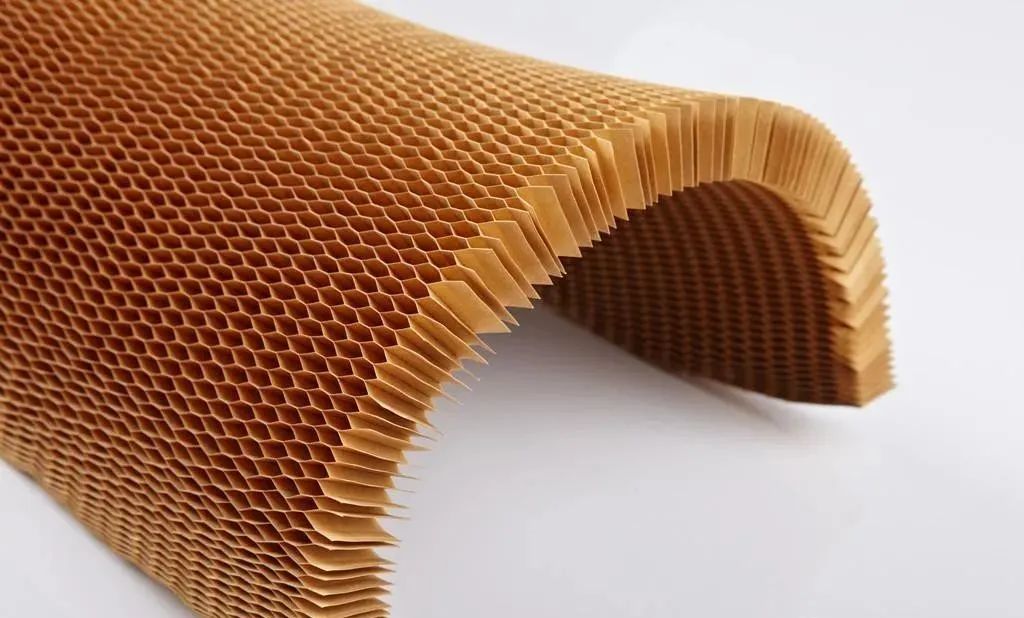

Typical applications are: body armor, conveyor belts, industrial filter cloths, fireproof materials, insulating paper, honeycomb shock-absorbing profiles, ropes, sports equipment, etc.

This article mainly introduces the application of aramid fiber in conveyor belt.

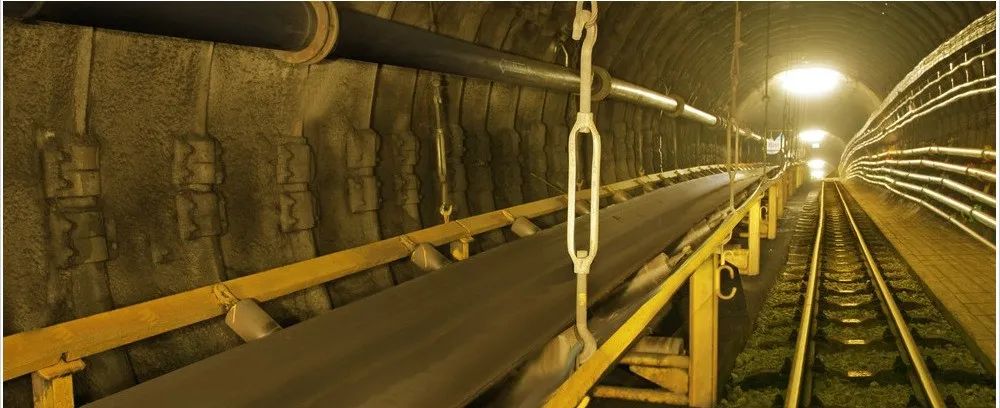

Conveyor belts are widely used in mines, ports, metallurgy, cement, and electric power industries. They have the advantages of large-capacity continuous transportation and low maintenance costs. At present, the length of a single long-distance conveyor belt can reach more than 10km, but some types of conveyor belts are due to The mass of the belt body is small, resulting in high energy consumption during operation and a decrease in effective conveying capacity. Therefore, under the environmental protection requirements of energy saving and emission reduction, it is the future development direction of conveyor belts to look for skeleton materials with light weight, high strength and low elongation, reduce belt mass, reduce maintenance costs, and prolong service life.

Comparing various fiber materials comprehensively, aramid fiber has the characteristics of high strength and modulus, small mass and low elongation, and is an ideal skeleton material in line with the development direction of conveyor belts. But at the same time, it has poor resistance to compression fatigue, so aramid conveyor belts need to pay attention to avoid fatigue caused by compression.

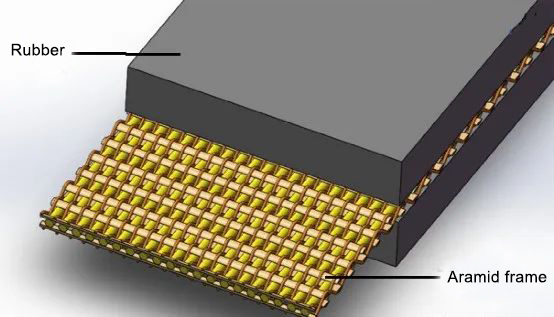

At present, aramid conveyor belts generally adopt a single-layer skeleton structure, aramid yarns are used in the warp direction, arranged in a straight line, and nylon cords are used in the weft direction. The main structures of aramid fabrics are cord structure and straight warp and straight weft structure.

Aramid Fiber Conveyor Belt Advantages

-

high strength

The aramid fiber skeleton layer has the characteristics of high strength and low mass. It usually adopts a single-layer skeleton structure, and the thickness of the upper and lower covering glue is small. Compared with steel wire conveyor belts of the same strength, it can greatly reduce the mass of the belt body and reduce energy consumption.

-

thinner and more flexible

The belt body of the conveyor belt is thinner and more flexible, and it can form a good groove with the roller during operation, and can also reduce the diameter of the driving wheel.

-

Better corrosion resistance

The steel wire skeleton conveyor belt is easily corroded by water vapor, etc., which affects the strength. The chemical corrosion resistance of aramid fiber is very good, and it is not easily affected by the external environment, such as water vapor, corrosive minerals, etc., which can prolong the service life of the conveyor belt.

-

Conveyor belt belt elongation is small

The elongation of aramid fiber is very small, only 20%-25% of nylon or polyester fiber. After running for a period of time, the elongation of the belt body is also very small, and the tension distance is smaller.

-

Good impact and tear resistance

The aramid conveyor belt with straight warp and straight weft structure has fiber reinforcement in the warp and weft directions, the whole skeleton layer structure is dense, and the belt body has good flexibility. When it is impacted by large materials, it can evenly disperse the force and has good resistance impact performance.

Application of Aramid Conveyor Belt

At present, aramid conveyor belts have been widely used in different fields in many countries around the world, such as thermal power plants, phosphate mines, coal mines, gold mines, and steel plants.