Application of Aramid Fiber in Electrical Insulation Fields

- 2023-02-09

Application of Aramid Fiber in Electrical Insulation Fields

1.1 Transformer

In terms of core wire, interlayer and phase insulation of transformers, the use of aramid fibers is undoubtedly an ideal material. It has obvious advantages in the application process, and the oxygen limiting index of fiber paper is >28, so it is a good flame retardant material itself. At the same time, the heat resistance reaches 220 grades, which can reduce the cooling space of the transformer, make its internal structure compact, reduce the loss of the transformer when it is no-load, and reduce the manufacturing cost. Because of its good insulation effect, it can improve the transformer's ability to store temperature and harmonic load, so it has important applications in transformer insulation. In addition, the material has good moisture resistance and can be used in wet environments.

1.2 motor

In the manufacturing process of motors, aramid fibers are widely used. The fibers and cardboard together form the insulation system of motor products, so that the products can operate under overload conditions. Due to the material's small size and good properties, it can be undamaged during the coil winding process. Its application methods include insulation between phases, leads, grounds, wires, slot linings, etc. For example: the fiber paper with a thickness of 0.18mm~0.38mm has good flexibility and is suitable for slot lining insulation; the fiber paper with a thickness of 0.51mm~0.76mm has a higher built-in hardness, so it can be used at the slot wedge position.

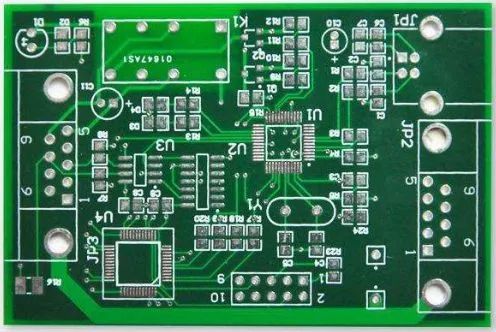

1.3 circuit board

After the application of aramid fibers in circuit boards, the electrical strength, point resistance, and laser speed are higher. At the same time, the machinability of ions is higher, and the ion density is lower. Due to the above advantages, it is widely used in the field of electronics. In the 1990s, circuit boards made of aramid materials became the focus of SMT substrate materials, and aramid fibers are widely used in circuit board substrates and other aspects.

1.4 Radar Antenna

In the rapid development of satellite communications, radar antennas are required to have the advantages of small mass, light weight, and high reliability. Aramid fiber has high stability in performance, good electrical insulation ability, and strong wave permeability and mechanical properties, so it can be used in the field of radar antennas. For example: it can be reasonably used in structures such as overhead antennas, radomes such as warships and aircraft, and radar feeders.

02 The specific application of aramid fiber in the field of electrical insulation and electronics

2.1 Application in various transformers

Aramid fibers can be used in dry-type transformers. Using aramid fibers at coil winding points can effectively increase the temperature index of the transformer insulation system and prolong its service life. The high temperature resistant insulation system is composed of fiber paper, high temperature oil, etc. It is used in railway traction equipment and power distribution equipment to reduce the quality and volume of transformers. In high-speed trains, aramid materials are used to form the insulation system of the transformer, which reduces the volume of the transformer to 80% to 85% of its original size, reduces the workload of its faulty maintenance, and improves the safety performance of the transformer. Make full use of the advantages of aramid fiber and apply it in the transformer as the main insulation material, which can ensure the safety of the structure. In oil-immersed transformers, aramid fibers can be used to manufacture transformers with high ignition points in conjunction with β oil with a high ignition point. This type of transformer has low operating cost and good fire performance. For example, the quality of a 150kVA transformer made of aramid fiber and silicone oil is not much different from that of a 100kVA transformer.

2.2 Application in various motors

Aramid fiber can be used in the insulation system of special motors, and the insulation performance of aramid fiber is good in frequency conversion speed regulating motors and 2500kV AC frequency conversion motors. At the same time, the use of aramid fiber to make epoxy resin composite material as the rotor protection ring of the engine can effectively solve the problem of weak performance of the traditional glass fiber latitude belt. Under normal conditions, the tensile strength of the sample is 1816MPa, so it can meet the requirements of high operating environment. In addition, aramid fiber can also be used as the structural insulation between the turns of the motor, which can reduce the thickness of the insulation layer, reduce the temperature rise rate of the motor, and improve the overall performance of the motor.

Aramid fibers can also be used in generators. After the fiber paper is soaked in epoxy resin, it is placed in the rotor coil to form an insulating structure, improve the mechanical strength of the coil, and shorten the manufacturing cycle of the generator. The researchers studied the Dongfang generator used in the Three Gorges unit and found that the unit uses aramid material as winding insulation, which not only meets the technical insulation requirements of the unit, but also can be used in large or medium-sized hydroelectric generators. .

In addition, aramid fiber can also be used in the grounding insulation of the motor to avoid the problem of abnormal shutdown of the motor. Aramid fiber and polyimide are used to form a composite material to form a closed lead wire. The inner and outer layers are braided by aramid fiber, which can make the motor have good insulation performance under lubricating oil and refrigerant conditions.

2.3 Application in printed circuit board

In the manufacturing process of printed circuit boards (hereinafter referred to as PCB), aramid fibers are used to synthesize high-density electronic chip lead supports. This type of support has strong tensile properties, so it can avoid copper sheets and resin substrates after being heated. problems of separation. In the electronics industry, the use of aramid materials to manufacture PCB boards can enhance the strength and quality of circuit boards. This kind of circuit board has a good size and an expansion coefficient of 3×10-6/℃. Due to the low dielectric constant of the circuit board, it is suitable for high-speed transmission of lines.

Compared with glass fiber materials, the mass of this circuit board is reduced by 20%, thus realizing the manufacturing goal of light weight and small system of electronic equipment. A Japanese company has developed a PCB board with better stability, higher flexibility, and stronger moisture resistance. In the manufacturing process, aramid fibers are used in the meta-position, which speeds up the preparation of epoxy-based resin materials. Compared with the application of the opposite material, it is easier to process and has better moisture absorption performance. PCBs made of aramid fibers are light in weight and strong in performance, and can be used in smartphones and tablet computers. In addition, current circuit boards based on aramid fiber with multi-layer structure can package high-density electronics, which are suitable for high-speed transmission of circuits and have been widely used in the military industry.

2.4 Applications in Antenna Components

Due to the good dielectric properties of the aramid material, it is applied in the radome parts, which is thinner than the traditional glass radome, with good stiffness and higher signal transmittance. Compared with the half-wavelength radome, the radome in the interlayer position uses aramid material to make the honeycomb interlayer. The core material is lighter in weight and higher in strength than the glass core material. The disadvantage is the cost of manufacturing. higher. Therefore, it can only be used in the manufacture of radome components in high-end fields such as shipboard radar and airborne radar.

2.5 Applications in other fields

In addition to the applications in the above fields, aramid fibers are also widely used in electronic components such as composite films, insulating ropes/rods, circuit breakers, and brakes. For example: In a 500kV transmission line, use insulating rope made of aramid material instead of insulating suspender as a load-bearing tool, and use insulating rope to connect the screw rod, which is conducive to promoting a safety factor above 3. The insulating rod is mainly composed of aramid fiber and polyester fiber intertwined, placed in a vacuum, immersed in epoxy resin material, and shaped after curing. It has good corrosion resistance during use, light weight and higher strength, and this material has good insulation performance. In the 110kV line, the operation of using insulating rods is relatively frequent, and its mechanical strength is high during application, and it has good dynamic fatigue resistance characteristics. In the manufacture of electrical machinery, the use of aramid fiber materials can improve the strength of components and prevent serious wear on the surface of molding replacements. It can replace glass fibers in electrical equipment. The fiber content of aramid fibers is 5%, and the length can reach 6.4mm. The tensile strength is 28.5MPa, the arc resistance is 192s, and the impact strength is 138.68J/m, so the wear resistance is higher.