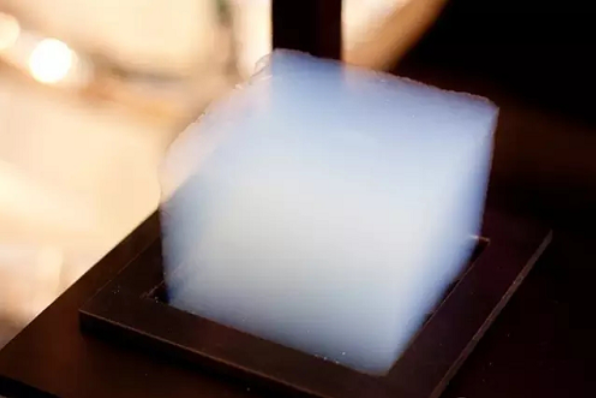

Silica aerogel makes "heat insulation" easier

- 2022-12-28

In today's society, energy conservation, consumption reduction, and emission reduction are advocated development models. Among the feasible measures, in addition to the efficient conversion of energy and the rational development of renewable energy, improving energy utilization efficiency is also the key to energy conservation, which is why "insulation materials" have begun to receive attention.

The reason for this is that the thermal insulation material can reduce the heat loss in the process of heat generation, transportation, storage and use by virtue of its extremely low thermal conductivity, so it is widely used in construction, chemical industry, electronics, clothing, aerospace, etc. field. Among them, the most typical representative is silica aerogel, due to its low thermal conductivity (<20.0mW/m K), dielectric constant (<1.7), refractive index (<1.1) and high Unique properties such as surface area (>1000.0m²/g) can play a role in many ways. Among all the proposed applications, potential candidates for thermal insulation applications are undoubtedly one of the most focused directions.

Thermal insulation principle of silica aerogel

The extremely low thermal conductivity of silica aerogel is mainly attributed to its unique nanopore and three-dimensional network structure. Since the pores of the aerogel are at the nanoscale, which is close to the mean free path of the phonons, when heat passes through the pores of the aerogel, the nanopores will have a serious scattering effect on the phonons, reducing the mean free path of the phonons and making the heat The efficiency of heat transfer through gas-solid coupling is reduced.

At the same time, the porosity inside the aerogel is very high, which can reach more than 90%, and the walls of the nanopores are like heat shields, which continuously reflect and refract thermal radiation. The infinite number of pore walls makes the radiation The heat transfer keeps decreasing; the aerogel pore size is similar to the mean free path of air molecules, and the gas molecules in the nanopores often lose the ability to flow freely, making the pores in a vacuum state, and the efficiency of convective heat transfer is close to zero.

Use of silica for thermal insulation

Silica aerogel is currently the solid material with the best thermal insulation performance. Because of its brittleness, different doping methods are generally used to improve the mechanical properties in application. At present, the application of related products has covered thermal insulation occasions such as scientific research, industry, national defense, etc., especially in aerospace and navigation fields. At the same time, it can also be used in various civil and industrial fields. The following are some applications of silica aerogel form.

1. Aerogel felt

Composite materials prepared by fiber reinforcement are generally called aerogel mats. At present, silica aerogel blankets are mainly used in thermal insulation buildings. Compared with traditional wall insulation materials such as rock wool, brickwork, and fiber in the market, aerogel felt not only has excellent thermal insulation performance, but also has corresponding mechanical strength, which can meet the heat insulation and thermal insulation requirements of wall insulation. strength requirements. What's more, the silica aerogel felt is made into a sandwich structure, so that it can be directly applied to external wall insulation.

2. Insulated glass

At present, China is the world's largest producer and user of glass curtain walls. Although it has excellent lighting and aesthetic advantages, glass curtain walls also cause excessive energy consumption due to heat absorption and light reflection. However, if aerogel is added to the glass curtain wall, it can increase the heat insulation capacity of the building and reduce the energy consumption of the glass curtain wall building without affecting the original lighting and aesthetics of the glass. Jensen et al. used porous silica aerogel to fill the middle layer of glass, and found that the thermal insulation performance was indeed enhanced, thus demonstrating the broad market prospect of silica aerogel windows, which is expected to become a great tool for energy saving and emission reduction in the future.

3. Thermal insulation coating/film

At present, research on aerogels in the field of coatings/films is gradually being carried out. In terms of coatings, Lu Bin and others from Central South University have mixed silica aerogel with water-based acrylic resin to prepare thermal insulation coatings for glass. Gao Shuya and others have prepared aerogel by mixing silica aerogel with epoxy resin Composite materials; In terms of thin films, Ni Xingyuan and others have made thermal insulation films composed of metal aluminum film and silica aerogel, which has increased the thermal insulation effect by five times.

The importance of "heat insulation" to improve energy utilization efficiency and realize energy saving, consumption reduction and emission reduction is obvious. Therefore, the research on the application of silica aerogel in heat insulation materials is very important for the efficient utilization of resources and energy, energy saving and emission reduction. Consumption reduction is of great significance.