How Aramid Achieves High Strength and Lightweight in Construction?

- 2022-11-03

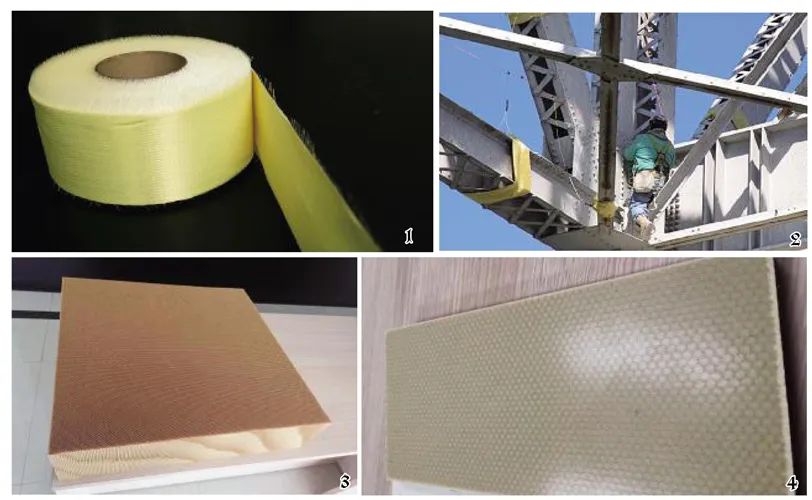

Aramid Unidirectional Fabric Provides Better Solutions for Building Reinforcement

-

What are the characteristics of para-aramid fiber, and what are the advantages of aramid fabric in the field of building reinforcement?

Para-aramid fiber is a new type of high-tech synthetic fiber. It has excellent properties such as ultra-high strength, high modulus, high temperature resistance, acid and alkali resistance, and light weight. Its specific strength is 5 to 6 times that of steel wire, and its modulus is Or 2 to 3 times that of glass fiber, the toughness is 2 times that of steel wire, and the weight is only about 1/5 of the steel wire, and it will not decompose or melt at a temperature of 560 ° C. Aramid fiber cloth composite material has high tensile strength, small specific gravity, good corrosion resistance, good elongation performance, good insulation performance, strong toughness, high shear strength and anti-extrusion strength, strong seismic performance, intrinsic flame retardant and other excellent It can be used for maintenance and reinforcement of bridges, columns, subways, chimneys, water towers, tunnels, electrified railways, seaports and wharves, and is especially suitable for reinforcement and repair of concrete structures.

-

Can aramid fiber cloth be used in composite applications with concrete structures?

The company's Teplon aramid unidirectional fabric products can be used in composite applications with concrete structures, and the scope is also relatively wide. For example, it is applied to beams, mainly bridges and civil buildings or industrial plants. The reinforcement methods include flexural resistance and shear resistance. When flexural reinforcement is performed, the fiber direction of the aramid fabric is consistent with the axial direction of the beam, and is generally attached to the beam. the tension side of the beam to improve the bearing capacity of the beam. According to relevant tests, as long as the beam is not an over-reinforced beam, one layer of 280g aramid fabric can increase the bearing capacity by about 30%, and two layers can increase the bearing capacity by about 40%; during shear reinforcement, the fibers of the aramid fabric The direction is perpendicular to the axis of the beam.

Aramid cloth is also an ideal material for reinforcing columns. First of all, because the elastic modulus of aramid is 118Gpa, compared with the elastic modulus of carbon fiber 230Gpa, the ductility of aramid is better; secondly, only about 10mm is required for edge grinding, and generally no grinding is required, while carbon fiber needs about 30mm. In contrast, using aramid fabric can save a lot of man-hours. Finally, since aramid fabric is a soft fabric, it has better followability, especially for platforms with irregular shapes, it is more suitable to use aramid fabric for reinforcement.

In the application of the reinforcement of masonry and slabs, generally the slabs have relatively high requirements for the reinforcement clearance, and the appearance of the slabs should not be affected after reinforcement, so it is more convenient to use thin and soft aramid composite materials for reinforcement. In the reinforcement of chimneys and water towers, due to the high-altitude structures such as chimneys and water towers, the reinforcement and maintenance are difficult. Traditional methods are basically difficult to solve such problems. Good, it will be a better choice for strengthening chimneys and water towers.

In the reinforcement of subway tunnels, aramid fabric also has certain advantages. Since subways and tunnels are structures that work underground, their stress is different from that of ground structures, and there is earth pressure on the top and side of the tunnel. It also has clearance requirements, so when repairing cracks, the possibility of using traditional reinforcement methods is very small. Reinforcement and maintenance with aramid fabric can meet all aspects of its requirements. Cracks in the vaults or sidewalls of subways or tunnels are generally multi-directional and irregular, which requires its repair materials to have good shear resistance, and aramid is also a non-conductive FRP material. Therefore, The advantages of aramid fabric in the reinforcement and application of tunnel subway engineering are still relatively prominent.

-

In the process of realizing the application in the construction field, what technical difficulties still need to be solved for aramid fabric? If it is widely used in the engineering field, how is its cost performance? Is there an advantage?

From the point of view of materials, the technical difficulties are mainly concentrated in the performance of raw silk and the level of weaving. Taihe New Materials strictly controls the quality of raw silk and weaving fabric. Taipulong aramid unidirectional fabric has been tested and certified by national authoritative institutions. All have reached the high-strength grade I standard stipulated by the national standard.

With the rising price of carbon fiber in recent years, the cost performance of aramid has reached the market acceptance range. The price of low-grade aramid fiber and low-grade carbon fiber is in the same range, and from the current market analysis, the stability of aramid fiber supply is higher than that of carbon fiber supply, while the price of high-grade aramid fiber is much lower than that of high-grade carbon fiber price. In the long run, the cost-effective advantage of aramid is still obvious.

However, the market has been accustomed to using carbon fiber for building reinforcement, and the awareness of aramid fiber is limited. In the face of such a situation, we need to increase the market's recognition of aramid fiber and increase its popularity.

Aramid paper honeycomb is the first choice for rail transit construction materials

-

What kind of material is aramid paper? What are the performance characteristics?

The company's main product, Minstar aramid paper, is a special new type of paper-based material made of pure aramid fiber. It has excellent mechanical strength, high temperature resistance, flame retardant, chemical corrosion resistance and good electrical insulation. It is an indispensable high-performance material for a wide range of applications such as aerospace, rail transit, new energy vehicles, and electrical insulation. Our main products can be divided into two categories: electrical insulating paper and honeycomb core paper.

The honeycomb structure material made of aramid paper has excellent characteristics such as light weight, high strength, high modulus, flame retardant, high temperature resistance, low dielectric loss, etc., and has become the preferred core material for honeycomb composite materials in the aerospace field.

-

What specific applications can aramid paper honeycomb have in urban and rural construction, rail transit, transportation and water conservancy?

Aramid paper is a high-performance insulating material, which can be used in high-end and complex working conditions for insulating systems. In urban and rural construction, it can be used as an insulating material for electronics, motors, UHV, power transformers, and distribution transformers. Used in high-speed rail, traction transformers for freight locomotives, traction motors, magnetic levitation linear motor insulation materials, high-speed rail interior parts and weight reduction materials, etc.; in aerospace, it can be used in commercial aircraft interior parts, secondary load-bearing parts, etc., aramid fiber The use of paper as the interior parts and structural parts of large aircraft will reach a very objective amount every year; in terms of transportation and water conservancy, it can be used in large-scale water conservancy generators, traditional car-inspired motors, and new-energy vehicle drive motors.

Aramid paper honeycomb also has good performance in noise reduction and thermal insulation. In the future, as a new material for green buildings and energy-saving buildings, it can also have more application space in the construction field.