-

-

Ceramic fiber cloth-Ceramic fabric-Insulation cloth

- Code:TCC-031

- Material:100% Ceramic fiber

- Weight:200GSM

- Function:High temperature resistance, low thermal conductivity, thermal shock resistance, low heat capacity, high temperature insulation performance

- Color:White

- Width:100CM

SEND INQUIRY

Product properties

-

High temperature resistance, low thermal conductivity, thermal shock resistance, low heat capacity.

-

Excellent high temperature insulation performance, long service life.

-

It has the ability to resist the corrosion of non-ferrous metals such as aluminum and zinc.

-

Has good low temperature and high temperature strength.

-

Good filtering, silencing and sealing performance.

Non-toxic, harmless, no adverse effects on the environment.

Product Description

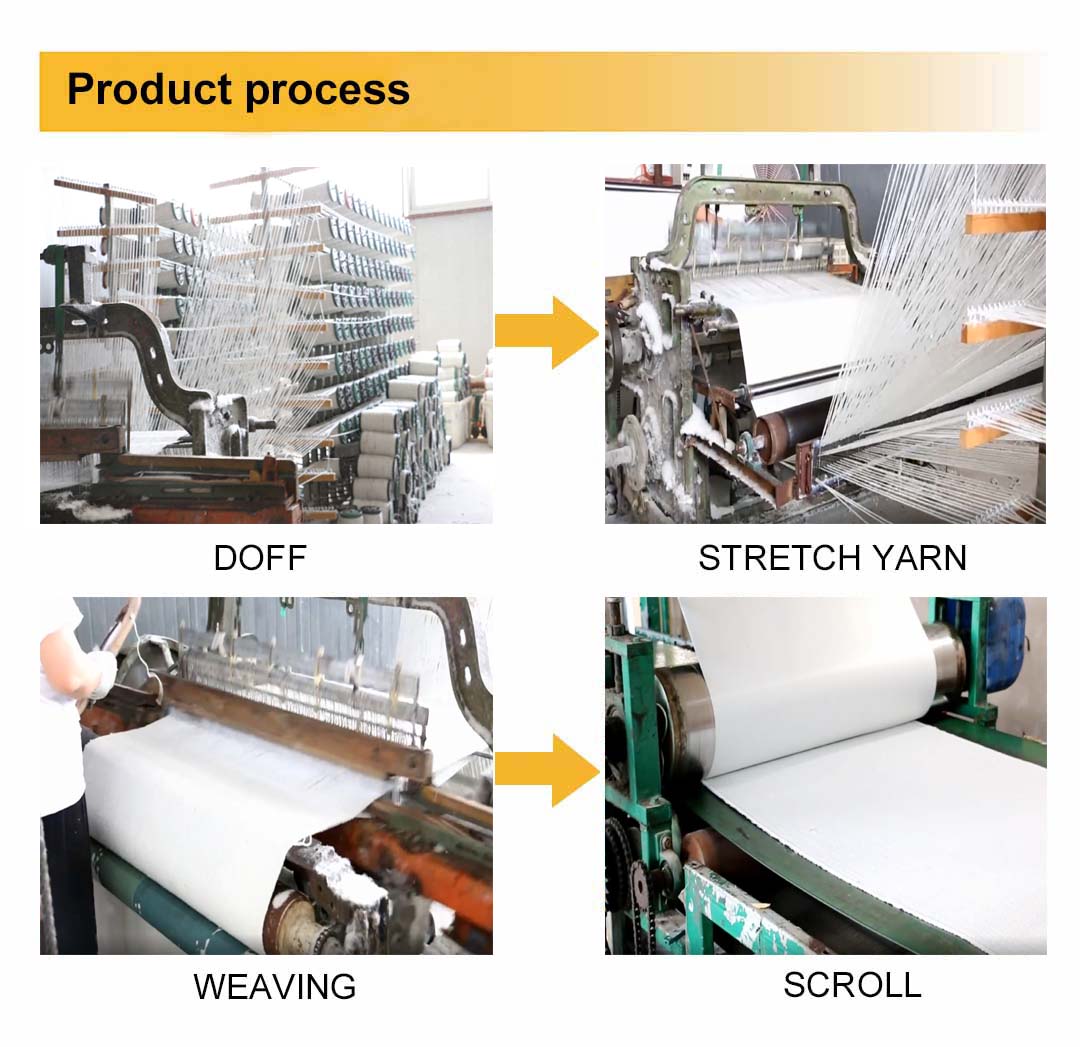

Ceramic fiber cloth is made of ceramic fiber plus a certain proportion of organic fiber, lined with glass fiber (steel wire), spun into yarn, and then woven into cloth. The general specifications and models of ceramic fiber cloth: 1.5mm--6mm, the general width is 1m, which is divided into (nickel-chromium alloy wire reinforced, stainless steel wire reinforced, glass fiber reinforced, ceramic fiber coated cloth, ceramic fiber slag cloth, ceramic fiber Fiber Sintered Cloth,

The amount of organic fiber determines the ablation rate, the type of organic fiber determines the flexibility of the cloth (from good to bad: viscose, polyester, pulp), the thickness of the glass determines the strength, and the material of the steel wire determines the corrosion resistance. Use less organic fiber viscose, glass fiber of suitable thickness, and 304 stainless steel wire. The twist in the spinning process determines the apparent smoothness of the cloth, and the number of previous batches determines the density of the cloth. Ceramic fiber cloth is characterized by high temperature resistance, low thermal conductivity, thermal shock resistance, and low heat capacity.

Product Application

It mainly used for large-area industrial heat insulation, coated fabrics, flexible expansion joints, high temperature resistant fire curtains, heat radiation shielding curtains, labor protection clothing, heat insulation curtains, etc.

General application of ceramic fiber cloth

①Insulation material for covering

②Interlining for sparks, protective clothing, gloves, helmets, boots

③Insulation of industrial kilns, furnace curtains, furnace fillers

④Composite brake friction pad

⑤Insulation of high temperature pipes and containers, protection of flue linings and fuel pipes

⑥Exhaust pipe wrapping of heavy oil engine, heat shield for automobile engine

⑦Cable covering and cable tray insulation, high temperature electrical insulation

⑧High temperature valve, flange seal

⑨ Fire doors, fire curtains, fire blankets

⑩ Metal melt filtration is a substitute for asbestos textiles and other high temperature resistant materials

Product Advantage

-

The continuous use temperature can reach 1000℃, and the short-term use temperature can reach 1260℃

-

It has good resistance to acid and alkali corrosion and corrosion of molten metal such as aluminum and zinc

-

Good high temperature strength and thermal insulation performance (please refer to physical and chemical indicators)

-

Ceramic fiber cloth, tape, packing and other series of products using alkali-free glass fiber filament as reinforcing material have higher electrical insulation and high-temperature electrical insulation than glass fiber

-

Non-toxic, harmless and odorless.

Precautions

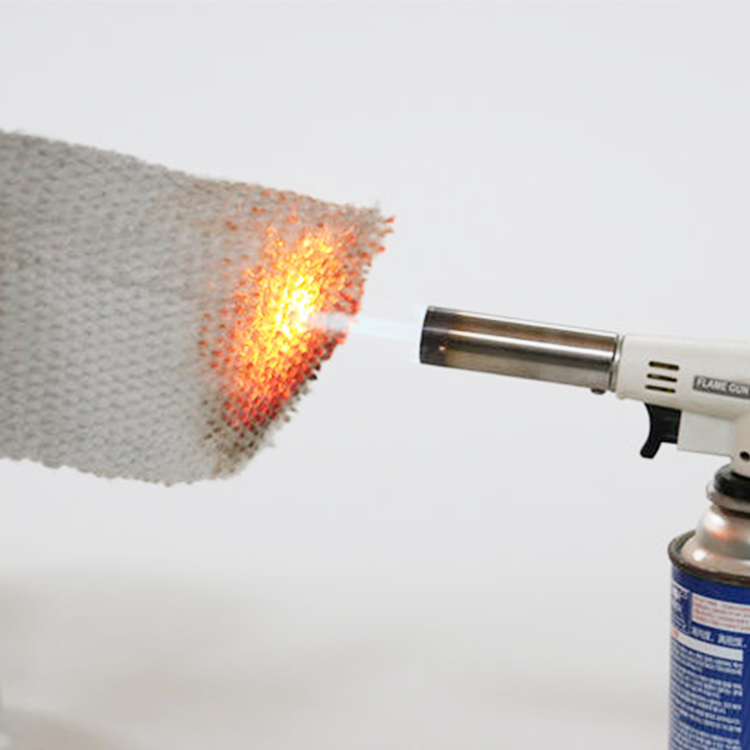

Ceramic fiber textiles contain about 15% organic fibers. When the temperature is raised for the first time, the organic fibers in the product will gradually carbonize and turn black, and there may be smoke. There may be flames in some places. This is a normal phenomenon and does not affect the use. As the temperature continues to rise, the product will gradually turn white again, the organic fiber has been completely carbonized, and the product is completely made of high-temperature resistant inorganic materials such as ceramic fiber.

Q1:Are you a factory? Where are you located?

A: We are a professional manufacturer with more than 5 years production experience of composite materials, We have two factories, one in Nantong, Jiangsu, China and the other in Bangkok, Thailand.

Q2:What's the MOQ?

A: Usually 100SQM.

Q3:Package & Shipping.

A: Normal package: by carton.

Q4:When can we offer?

A: We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price pls call us or send email to us, so that we can reply you with priority.

Q5:How do you charge the sample fees?

A: If you need a samples from our stock, we can provide to you for free, but the free charge should be on your side. If you need a special size, We will charge the sample making fee which will be refund when you place an order.

Q6:What's your delivery time for production?

A:If we have stock , can delivery in 1-7 days, if without stock, need 5-30 days, depend on quantity.

Q7:What is your payment term?

A: Paypal, T/T, L/C AT sight, D/P and Western Union