What are the key differences between carbon fiber and steel?

- 2022-04-29

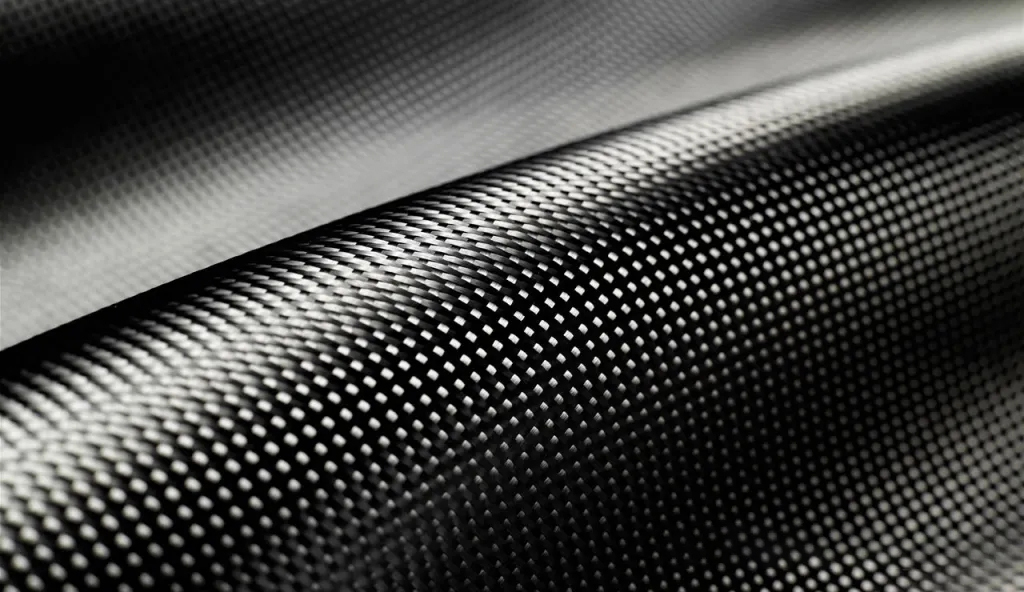

Benefiting from the characteristics of high specific strength and high specific modulus, carbon fibers have been widely used in many applications. Sometimes people compare carbon fiber to metallic steel. When comparing carbon fiber and metallic steel, it is not difficult to see that both carbon fiber and steel have properties that provide unmatched performance in specific applications. But if you want to understand which material is better, you need to know the key difference between carbon fiber and steel. This article will take you briefly to understand the characteristics and main differences between carbon fiber and steel.

The main difference between carbon fiber and steel

Both steel and carbon fiber are common in industrial and everyday applications, and both are primarily known for their superior strength and durability. In everyday applications, both steel and carbon fiber are reliable materials that can withstand long-term wear. But of course, there are some notable differences between the two. Mainly reflected in the following aspects:

01. Strength

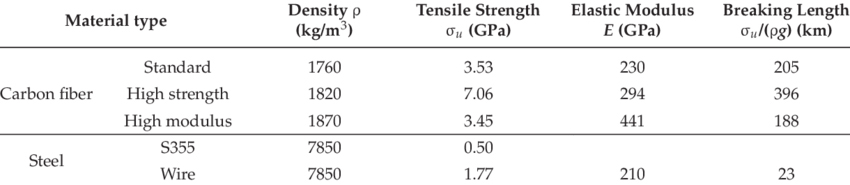

While steel is often considered the standard material in construction and industrial settings, carbon fiber is actually much stronger than steel in terms of strength-to-weight ratio. When applied, strength is defined by a material's resistance to deformation, or modulus of elasticity. Both carbon fiber and steel have elastic moduli above 200 gigapascals (GPa), so both materials are very stiff and ideal for many applications in high stress areas.

Since carbon fiber and steel have similar elastic moduli, how can it be said that carbon fiber is stronger?

This is an excellent point which leads us to the next feature...

02. Weight

Although both carbon fiber and steel have strong deformation resistance, the density of steel is much higher than that of carbon fiber. Generally speaking, the weight of carbon fiber is only about one-fifth of that of steel, so that is to say, under the same weight, carbon fiber The strength is about five times that of steel.

Due to its unmatched strength-to-weight ratio (specific strength), carbon fiber is the first choice for some applications where weight must be kept to a minimum (e.g. aerospace, sporting goods, etc.).

03. Corrosion resistance

Cured epoxy can react to sunlight and other elements, but carbon fiber itself is made of a chemically stable material and is resistant to corrosion, making it perfect for applications in harsh environments.

Steel, on the other hand, is extremely susceptible to oxidation when exposed to atmospheric moisture (although some alloy steels have better corrosion resistance), so carbon fiber is undoubtedly superior in terms of corrosion resistance.

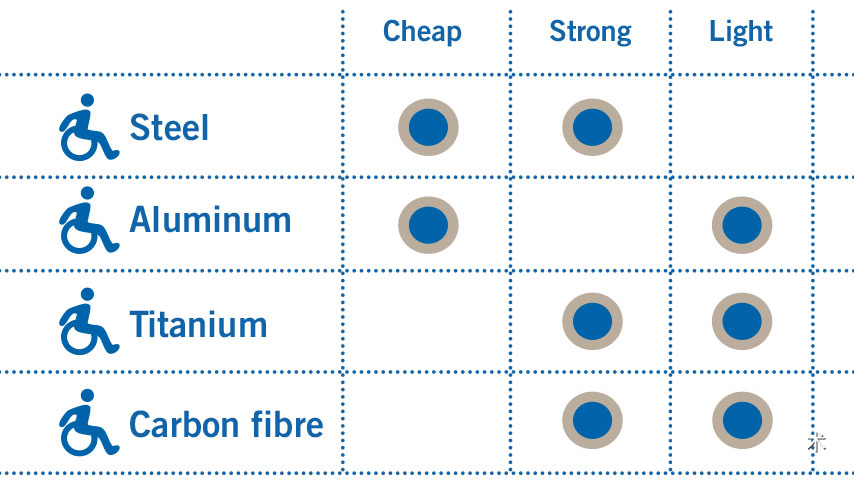

04. Cost

Steel is generally a more cost-effective material than carbon fiber. In contrast, there are many factors affecting the cost of carbon fiber, mainly including the cost of the manufacturing process, the cost of skilled labor and the cost of materials. So, producing carbon fiber is a very time-consuming process, but it's worth it in the end. While carbon fiber components may cost slightly more, they are stronger, lighter, and much more durable than steel components.

To sum up, both steel and carbon fiber are very strong, and depending on what they are used for, their construction is durable. Both have their own strengths and positions in industrial settings, and it's safe to say that carbon fiber won't replace steel anytime soon.