China's key high-performance fiber: aramid fiber!

- 2022-07-28

The full name of aramid fiber is aramid fiber, and it is Aramid fiber in English. It is listed as the four major high-performance fibers in my country together with carbon fiber, ultra-high molecular weight polyethylene fiber and basalt fiber.

Aramid fiber and ordinary nylon are both amide fibers, and both contain amide bonds in the main chain of macromolecules. The difference is that the amide bonds of nylon are connected to aliphatic groups, while the amide bonds of aramid are connected to benzene rings.

Types of Aramid Fibers

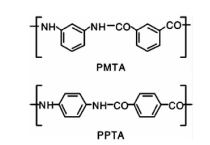

Aramid fibers mainly include wholly aromatic polyamide fibers and heterocyclic aromatic polyamide fibers, which can be divided into ortho-aramid fibers, para-aramid fibers (PPTA) and meta-aramid fibers (PMTA). The industrialized products mainly include meta-aramid and para-aramid. The main difference between these two types of aramid is the difference in the attachment position of the amide bond to the C atom on the benzene ring.

✪ Para-aramid

Para-aramid fiber, namely polyparaphenylene terephthalamide (PPTA), called aramid fiber 1414 in my country, is a linear polymer in which more than 85% of the amide bonds in the molecular chain are directly bonded to the aromatic ring. It is the world's first fiber made from polymer liquid crystal spinning solution, creating a new era of high-performance synthetic fibers.

✪ Meta-aramid

Meta-aramid fiber, namely polymetaphenylene isophthalamide (PMTA), also known as aramid fiber 1313 in my country. Meta-aramid fiber is the fastest growing seed crystal in organic high-temperature resistant fibers. The fiber molecules are composed of amide groups connected to each other with meta-phenyl groups. The molecular chain is linear and zigzag. It has excellent flame retardancy, thermal stability, radiation resistance and other properties.

Excellent properties of aramid fibers

It has excellent properties such as ultra-high strength, high modulus and high temperature resistance, acid and alkali resistance, light weight, insulation, anti-aging, long life cycle, stable chemical structure, no molten droplet burning, no poisonous gas and so on.

The temperature resistance of para-aramid fiber is higher than that of meta-aramid fiber. The continuous use temperature range is -196 to 204 °C, and it does not decompose or melt at a high temperature of 560 °C. The most notable characteristics of para-aramid are ultra-high strength, high modulus, high temperature resistance, acid and alkali resistance, light weight and other excellent properties. 3 times that of high-strength nylon industrial yarn; the modulus is 2 to 3 times that of high-quality steel or glass fiber, and 10 times that of high-strength nylon industrial yarn; the toughness is twice that of steel wire, and the weight is only about 1/5 of that of steel wire , it has good insulation and anti-aging properties, and has a long life cycle.

✪ Good mechanical properties of aramid fiber

Meta-aramid is a kind of flexible polymer, its breaking strength is higher than that of ordinary polyester, cotton, nylon, etc., its elongation is large, its hand feel is soft, and its spinnability is good. It can be produced into short fibers and filaments of different denier and length. , In general textile machinery, different yarn counts are woven into fabrics and non-woven fabrics, and after finishing, they can meet the requirements of protective clothing in different fields.

✪ Excellent flame retardant and heat resistance of aramid fiber

The limiting oxygen index (LOI) of meta-aramid is greater than 28, so it does not continue to burn when it leaves the flame. The flame retardant properties of meta-aramid fiber are determined by its own chemical structure, so it is a permanent flame retardant fiber, and its flame retardant properties will not be reduced or lost due to use time and washing times. Meta-aramid fiber has good thermal stability, can be used continuously under the condition of 205℃, and can still maintain high strength under the condition of high temperature above 205℃. Meta-aramid fiber has a high decomposition temperature, and will not melt or drop under high temperature conditions, and carbonization will only start when the temperature is greater than 370 °C.

✪ The chemical properties of aramid fibers are stable

Meta-aramid fiber has excellent resistance to most chemical substances, can resist most high concentrations of inorganic acids, and has good alkali resistance at room temperature.

✪ Radiation resistance of aramid fiber

The radiation resistance of meta-aramid is very good. For example, under long-time irradiation of 1.2×10-2 w/in2 ultraviolet rays and 1.72×108 rads of gamma rays, the intensity remains unchanged.

✪ Durability of aramid fiber

Meta-aramid fiber has excellent friction resistance and chemical resistance. After 100 times of washing, the tearing strength of the fabric processed with Newstar® meta-aramid fiber can still reach more than 85% of the original strength.

Fields of application of aramid fibers

✪ Aviation field

Aramid fiber has low density, high strength and good corrosion resistance. It can be used to manufacture rocket engine casings of missiles, as well as broadband wave-transmitting materials such as the fuselage, main wing and tail of aircraft and spacecraft, as well as structural components that can withstand impact forces. The multi-layer honeycomb structure board is prepared by impregnating aramid fabric with epoxy resin to form aramid prepreg and directly bonding with honeycomb or foam structure, which has outstanding impact resistance and electromagnetic wave permeability. The super-mixed composite laminate formed by overlapping aramid fiber with thin aluminum plate and epoxy weft-free cloth and hot pressing has extremely high specific modulus and specific strength, and the fatigue resistance life is 100 times to 1000 times that of aluminum alloy plate. It can be used in the fuselage and other parts of the aircraft. The resin-based reinforced composite material prepared by aramid fiber is used in the aircraft passenger body, which can greatly reduce the total weight of the aircraft.

✪ Military field

With the development of new military weapons such as chemical and nuclear, there are more new requirements for the performance of military protective clothing: durable, lightweight, bulletproof, flame retardant, and good environmental adaptability and camouflage. Bulletproof vests and bulletproof helmets made of aramid fibers can replace the old nylon vests and tank helmets. Adding an appropriate amount of aramid to the bulletproof vests and helmets can not only make them small and light, but also increase the bulletproof performance by 40%. . The soft bulletproof vest made of high-grade bulletproof aramid non-woven fabric and high-performance polyethylene film has better ballistic resistance and heat resistance than ultra-high molecular weight polyethylene fiber. Aramid fiber can also be compounded with other materials (such as metal, ceramics, etc.) to make various high-strength, impact-resistant explosion-proof tanks, bulletproof shields and bulletproof armor plates. In addition, the aramid fiber fabric is bonded to the inner wall of the structure, which can effectively absorb the explosion wave and prevent the damage of the shrapnel to the human body.

✪ Construction field

The ductility of aramid fiber fabric is better than that of carbon fiber. The material itself is light in weight and flexible in degree of freedom. It is an ideal reinforcement material for construction projects, especially when reinforcing irregular-shaped components. There is no need to do chamfering. The aramid fiber is woven into a steel bar shape, which can be used as a cement-reinforced skeleton for large buildings. In addition to the advantages of high strength and light weight, it is also resistant to corrosion and can also play a good role in shear resistance.

✪Transportation

Due to the low density of aramid fiber, it can withstand high and low temperatures, and has good adhesion to rubber, and can be used as tire cords for automobiles or airplanes. The tire made of aramid fiber has light weight, thin tire, low rolling resistance, high tire bearing capacity, good wear resistance, cutting resistance and puncture resistance, and the center of gravity of ground pressure during tire use The movement is small, the steering performance is good, the heat is easy to dissipate, and it is not easy to deform, which improves the ride comfort of the car, prolongs the service life of the tire, and can meet the requirements of modern supersonic aircraft for the use of tires.

✪ Electrical and electronic fields

Aramid fiber has high strength and modulus and low dielectric coefficient, and has good electromagnetic wave transmittance. Under the same stiffness conditions, the thickness of the radar antenna shield made of aramid fiber composite material can be reduced by 30% compared with glass fiber composite material. %, the electromagnetic wave transmittance is increased by 10%; the linear expansion coefficient of the composite substrate made of aramid fiber and epoxy, phenolic, polyimide and other resins and ceramics has a high degree of matching, and will not be affected by thermal expansion and contraction. It can cause cracking and can be used to make special printed circuit boards in surface mount technology, which is conducive to the miniaturization and light weight of electronic equipment.

Utilizing the characteristics of high strength and high temperature resistance of aramid fiber, it is used as a "tension member" in the optical fiber, which can protect the small and fragile optical fiber from being stretched and deformed under tension, and will not affect the transmission of light. The composite product of aramid fiber and carbon fiber has good processability and semiconductivity, and can withstand high temperature. It is mostly used to make materials for reducing electric field in high-voltage devices. After being impregnated with insulating paint, aramid paper has good insulating properties, and is used as an insulating material for heat-resistant motors in combination with natural mica sheets.

✪Other fields

Aramid fiber molecules contain a large number of benzene rings, which have good chemical stability, corrosion resistance, high specific strength, light weight and firmness, and can be used to manufacture cables for marine vessels and deep oil wells. Using the characteristics of high temperature resistance and fatigue resistance of aramid fiber to make high-grade rackets, fishing rods, sleds, snowboards, ski poles, bows and arrows, rowing boats, golf clubs, etc., it can also be used to make mountaineering shoes with harsh sports conditions Boots, boxing gloves, racing helmets, racing body, etc. Since asbestos is seriously harmful to the human respiratory tract, aramid fiber can be used to replace asbestos to make seals such as reinforced rubber sealing plates, which are used for gaskets and gaskets of automobile brakes.

At present, domestic and foreign companies producing aramid fibers mainly include DuPont, Teijin, Taihe New Materials and so on.

✪DuPont

DuPont, founded in 1982, is a global enterprise based on scientific research. Its products and services cover many fields such as agriculture and food, building and construction, communication and transportation, energy and biological application technology. In 1972, DuPont realized the industrialization of para-aramid fiber, and its global market share with Teijin exceeded 75%. By the end of 2020, DuPont had a production capacity of 32,000 tons of para-aramid and 22,000 tons of meta-aramid.

✪ Teijin

Teijin, founded in 1918, is the first rayon company in Japan. In 1987, Teijin realized the industrialization of para-aramid fiber. By the end of 2020, Teijin had a production capacity of 32,000 tons of para-aramid fiber and 5,000 tons of meta-aramid fiber.

✪ Taihe New Materials

Taihe New Materials, established in 1993, is a national high-tech enterprise specializing in the research and development, production and application development of high-performance fibers. It has taken the lead in realizing the industrialized production of spandex, meta-aramid and para-aramid in my country. It fills many gaps in the domestic high-performance fiber field and is a leading enterprise in my country's para-aramid fiber industry. By the end of 2020, Taihe New Materials had a production capacity of 4,500 tons of para-aramid and 11,000 tons of meta-aramid.