Polyimide: the top of the polymer pyramid!

- 2022-07-21

1. Introduction of polyimide

Polyimide (PI) is an aromatic heterocyclic polymer compound whose molecular structure contains imide chain units. It is one of the best heat-resistant varieties in engineering plastics. It is widely used in aviation, aerospace, microelectronics, Nano, liquid crystal, laser and other fields.

Recently, all countries have listed the research, development and utilization of PI as one of the development priorities of new chemical materials in the 21st century. Polyimide, because of its outstanding characteristics in performance and synthesis, has great application prospects, whether as a structural material or as a functional material.

Polyimide is known as the top material of the pyramid of polymer materials, and is also known as a "problem-solving expert", and even some people in the industry believe that "without polyimide, there would be no microelectronics technology today.

2. Classification and application of polyimide

Due to its excellent properties, polyimide can be used in various fields and can also be divided into various types, including engineering plastics, fibers, photosensitive polyimides, foams, coatings, adhesives, films, aerogels, composites materials, etc.

Among the many polymers, polyimide is the only polymer that has a wide range of applications and shows outstanding performance in each application. Below, the editor will take you to understand the main uses of various types of polyimide.

1. Engineering plastics

Polyimide engineering plastics can be divided into both thermosetting and thermoplastic, which can be divided into polypyromellitic tetracarboximide (PMMI), polyetherimide (PEI), polyamide-imide (PAI), etc. It has its own uses in different fields.

PMMI has a thermal deformation temperature of 360°C under a load of 1.8MPa, and has excellent electrical properties. It can be used for precision parts under special conditions, high temperature self-lubricating bearings, sealing rings, blower impellers, etc. It can also be used for valve parts in contact with liquid ammonia. , jet engine fuel supply system parts.

PEI has excellent mechanical properties, electrical insulation properties, radiation resistance, high temperature resistance and wear resistance, good melt fluidity, and a molding shrinkage rate of 0.5% to 0.7%. It can also be combined with other materials by welding, and is widely used in electronic appliances, aviation, automobiles, medical equipment and other industries.

The strength of PAI is the highest among the current non-reinforced plastics, with a tensile strength of 190 MPa, a bending strength of 250 MPa, and a thermal deformation temperature of up to 274 °C under a load of 1.8 MPa. PAI has good ablation resistance and electromagnetic properties at high temperature and high frequency, and has good adhesion to metals and other materials. It is mainly used for gears, bearings and copier separation claws, etc. It can also be used for ablation of aircraft materials, magnetically permeable materials and structural materials.

2. Polyimide fiber

Polyimide fiber is an important high-performance fiber, and its high temperature resistant polyimide fiber is one of the organic synthetic fibers with the highest temperature at present. Compared with aramid fiber and polyphenylene sulfide fiber, the thermal properties and other aspects are superior. The strength of high-performance polyimide fiber is about 1 times higher than that of aramid fiber, and it is one of the organic synthetic fibers with the best mechanical properties at present. .

With the continuous development of the high-tech field, the requirements for the physical and chemical properties of PI products are getting higher and higher. The mechanical, thermal, optical, electrical, magnetic and other properties of traditional PI materials can no longer meet the special requirements of materials in the modern scientific and technological field. It is required that PI high-performance fibers will become a typical representative of the next generation of high-performance fibers due to their superior mechanical properties, thermal stability, and radiation resistance.

At present, the main domestic companies engaged in PI fiber industry are Jiangsu Aoshen, Changchun Gaoqi, Keju New Materials, Jiangsu Xiannuo, etc. Among them, Changchun Gaoqi has become an important base for polyimide research, development and production in my country. Jiangsu Xiannuo, a high-performance organic fiber with completely independent intellectual property rights, passed the appraisal of scientific and technological achievements in 2016, and took the lead in 2020. Completed the formulation of the national standard "High Strength and High Modulus Polyimide Filament".

3. Photosensitive Polyimide (PSPI)

Photosensitive polyimide (PSPI) is a kind of organic material with imine ring and photosensitive gene in the polymer chain, which combines excellent thermal stability, good mechanical properties, chemical and photosensitive properties.

Photosensitive polyimide has two major functions in the field of electronics: photoresist and electronic packaging. "Polyimide photoresist" can be obtained by adding sensitizers and stabilizers to photosensitive polyimide. Compared with traditional photoresist, because polyimide itself has good dielectric properties, there is no need to apply a photoresist that acts as a working medium during use, which can greatly shorten the process and improve production efficiency.

The production technology of photosensitive polyimide (PSPI) is mainly controlled by American and Japanese companies. Among them, Toray is one of the most successful companies in the marketization of neutral PSPI products in the world. Its positive products are used in microelectronic packaging. , optoelectronic packaging and other fields.

Limited by the backward production technology, my country's polyimide industry is still stable with low-end products such as films, the output of photosensitive polyimide is relatively small, and the market demand depends on imports. With the support of the "Made in China 2025" policy, my country's industry, machinery, electronics and other fields have entered the stage of domestic substitution. Domestic enterprises continue to deepen their understanding of PSPI, and some enterprises have mastered production technology.

At present, local companies that deploy PSPI R&D and production include Ruihuatai, Mingshi New Materials, Guofeng Plastic Industry, Dinglong Technology, etc. There is a large space for domestic alternatives in this field in the future.

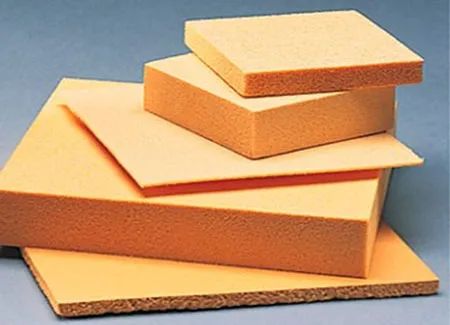

4. Polyimide foam

Polyimide foam is a type of polyimide material. It was first developed by NASA Langley Research Center in cooperation with Unitika America in the 1970s. It is used in space shuttles and is now widely used in aircraft and ships. , trains, automobiles and other fields, it has the characteristics of intrinsic flame retardant, strong heat resistance, light weight, environmental protection and non-toxicity, and can be used in extreme conditions such as ultra-high temperature, ultra-low temperature, high salt spray, strong noise, strong corrosion, and strong radiation serve under.

Polyimide foam can be divided into three categories:

(1) The same as general polyimide, the use of imide as the main chain of the foam material, the use temperature is above 300 ℃ (PI foam)

(2) Foam material (PMI foam) in which imide rings exist in the form of side groups

(3) Nano-foam materials obtained by introducing thermally unstable aliphatic segments into polyimide and cracking at high temperature.

Polyimide foam materials are advanced functional materials and have been increasingly used in key materials such as heat insulation, shock absorption and noise reduction, and insulation in high-tech fields such as aerospace, ocean transportation, national defense, and microelectronics.

At present, the most important application of PI foam is thermal insulation and noise reduction materials for ships. At present, our navy is in the third climax of shipbuilding. As the preferred thermal insulation and noise reduction material in new warships, the demand for PI foam is rapidly increasing.

Polymethacrylimide foam (PMI for short) is a new type of polymer structural foam material with the best comprehensive performance. It is a high specific strength, high specific modulus, high closed cell rate and high heat resistance. Performance composite foam core material, featuring light weight, high strength and high/low temperature resistance. In addition, as the most excellent structural foam core material, PMI foam is widely used in wind turbine blades, helicopter blades, aerospace and other fields. Its replacement trend for PET foam is clear and the market space is broad.

PI foam has strong heat resistance, good flame retardancy, does not produce harmful gas, and is easy to install. It is a widely used thermal insulation and noise reduction material. At present, the U.S. Navy has used PI foam as a thermal and sound insulation material for all surface ships and submarines. SOLIMIDE foam produced by INSPEC has been developed by more than 15 countries for thermal and sound insulation systems for naval ships. In addition, PI foam It is also widely used in civilian ships, such as luxury cruise ships, speedboats, and LNG ships.

Similar to PI foam, PMI foam is also widely used. Typical applications for PMI foam include:

(1) Structural foam core material: excellent high temperature compression resistance, making it widely used as a core material in fan blades, aviation, aerospace, ships, sports equipment, medical equipment and other fields;

(2) Broadband wave-transmitting material: low dielectric constant and loss make it widely used in radar, antenna and other fields;

(3) Thermal and sound insulation materials: high-speed locomotives, tires, speakers, etc.

Since the 21st century, the number of units participating in polyimide foam research in my country has increased significantly, and major breakthroughs have been made in industry technology. At present, the main domestic manufacturers of polyimide foam are Qingdao Ocean, Kangda New Materials, Tiansheng New Materials, Zigong Zhongtiansheng, Qingdao Ocean New Materials, etc. Among them, the Ningbo Institute of Materials, Chinese Academy of Sciences has built a pilot plant for polyimide micro-expanded particles, and the polyimide products of Qingdao Ocean and Kangda New Materials have passed the military test.

5. Polyimide coating

The use of polyimide in the preparation of coatings is one of its earliest applications, and these substances are mainly used as insulating coatings for enameled wires in coatings. The insulating coating of enameled wire mainly dips and coats the outer layer of various types of naked copper wire, alloy wire and glass wire covered wire such as round wire and flat wire, so as to improve and stabilize the outer layer of the enameled wire.

One of the important indicators of insulating coatings is the heat resistance level. According to the ICE-85 thermal stability classification standard for electrical insulation materials in use formulated by the International Electrotechnical Association in 1954, the insulating materials are divided into 7 heat resistance levels.

The characteristics of insulating materials that meet the requirements of industrial technology development are that the insulation system should be able to work for a long time at 180-200 ℃ or higher, without significant weight loss and electrical strength reduction, and maintain good elasticity, moisture resistance, Ozone resistance, arc resistance and other properties. Polyimide materials can well meet this requirement to prepare insulating coatings with heat resistance grades of F and above. Polyimide can be used as insulating paint for magnet wires, or as high temperature resistant coatings.

6. Polyimide adhesive

PI (polyimide) adhesive is a kind of organic heterocyclic adhesive containing imide cyclic structure in the main chain. It has excellent high temperature mechanical properties, dielectric properties and radiation resistance properties. Hydrolysis has been widely used in high-tech fields such as aerospace, precision electronic machinery, etc., and has solved the problems of lower upper limit heat resistance temperature of other organic adhesives.

Since the 1970s, NASA Langley Research Center, DuPont and Hughes Aircraft Company have successively developed a series of high-performance products codenamed LARC-TPI, NR-150R2PI-S02 and LARC-13. The high temperature resistant PI adhesive that is guided and has been widely used in a variety of aircraft. In the 1990s, Amoco and Cytec companies in the United States, and Mitsui Toyo Chemical Co., Ltd. in Japan have become the most famous companies in the world for the production of Pl adhesives.

7. Polyimide film

In the early morning of December 8, 2018, the Chang'e-4 probe was launched from the Xichang Satellite Launch Center, marking my country's first soft landing on the far side of the moon, a major breakthrough in lunar patrol detection and moon night survival. This time, Chang'e-4 successfully brought the national flag to the back of the moon, marking the "China logo" for space.

It is reported that the national flag of the probe is not made of common chemical fiber fabrics, silk, cotton and other textiles.

As we all know, the space environment is very special. There is no atmosphere on the surface of the moon. When it is in a vacuum state and exposed to sunlight, the maximum temperature of the surface of the moon during the daytime can reach 123 °C. At night, outside the lunar module, the temperature on the moon plummets to minus 233 degrees Celsius.

Such a temperature difference is unbearable for ordinary materials, and the ultraviolet rays generated by the sun are very strong, and there are also radiation effects of cosmic rays and high-energy particles, which have a strong destructive effect on materials.

The national flag material entrusted with the important task is polyimide organic polymer film, which is completely different from the common flag on the ground. It can withstand the harsh environment of the lunar surface, and will not fade or deform.

In addition to being used as the "coat" of spacecraft and its application in the military, polyimide film can be seen in the fields of microelectronics, nanometers, liquid crystals, separation membranes, lasers, and new energy. For example, transparent polyimide films can be used as flexible solar cell backplanes; PI can be used as next-generation lithium-ion battery separator materials, and so on.

In recent years, with the development of the electronics industry, high-performance polyimide film has become a key material for microelectronics manufacturing and packaging, and is widely used in the manufacture of ultra-large-scale integrated circuits, automatic bonding of carrier tapes, flexible packaging substrates, and flexible connecting tapes. lines, etc.

In addition, polyimide is an ideal material for high temperature resistant gas separation membranes because of its high heat resistance and good overall performance. At present, a very small amount of polyimide varieties are used in high temperature resistant gas separation membrane materials for the separation of various gas pairs (such as hydrogen/nitrogen, nitrogen/oxygen, carbon dioxide/nitrogen, carbon dioxide/methane, etc.), from air, It can also be used as pervaporation membrane and ultrafiltration membrane to remove moisture from hydrocarbon feed gas and alcohols. However, conventional polyimide resins are difficult to dissolve and melt, thus limiting the possibility of their wide industrial application.

8. Polyimide Aerogel

Polyimide aerogel (PIA) is an inter-crosslinked three-dimensional porous material composed of polymer molecular chains. It combines the excellent properties of polyimide and aerogel. It not only has the excellent characteristics of polyimide, but also Moreover, it has the outstanding characteristics of light weight and ultra-low density, high specific surface area, low thermal conductivity, low acoustic impedance, environmental durability and low dielectric constant of aerogel. These special properties make polyimide aerogel materials in It has excellent application prospects in the fields of heat, electricity, mechanics, and acoustics.

Photo 6 (Polyimide Aerogel)

In order to realize the manned Mars landing plan, the NASA research center applied polyimide aerogel materials to the research of supersonic inflatable aerodynamic reducer (HIAD) when developing heavy-load transportation technology. The payload and volume benefits of braking provide a solution, and due to the durability of polyimide aerogel materials, it also has a wide range of applications in propellant tanks, ultra-light multifunctional materials for rovers, and space habitats. application prospects.

In addition to the aerospace field, polyimide aerogel materials have good application prospects in the fields of electronic communication, heat insulation and flame retardant materials, adsorption and cleaning, sound insulation and sound absorption, catalytic carriers, and wire/cable insulation layers.

9. Polyimide Matrix Composites

Fiber-reinforced composite materials are a new generation of lightweight materials after magnesium-aluminum alloys. Polyimide-based composite materials have excellent high temperature resistance and tensile properties, and are widely used. Polyimide resin-based composite materials have the characteristics of high heat resistance of polyimide, excellent mechanical properties, dielectric properties, solvent resistance, etc., and are currently the resin-based composite materials with the highest temperature. engine), aerospace and other fields have been widely used.

After nearly 40 years of development, polyimide high temperature resin-based composite materials have developed four generations of composite materials, and the operating temperature has been continuously improved. At present, the most advanced fourth-generation polyimide resin-based composite materials can be used in 450 ℃ for long time use.

At present, the application and research and development of polyimide composite materials in my country are still catching up, and enterprises such as AVIC Composite Materials Co., Ltd. have been able to produce the third-generation resin products.

In addition, with the gradual maturity of the carbon fiber industry, the demand for carbon fiber reinforced composite materials has increased significantly. As one of the most excellent composite material combinations, the combination of polyimide and carbon fiber has obvious advantages in seizing the high-end market.

Polyimide covers almost all types of polymer materials, including high-performance films, engineering plastics, foamed plastics, chemical fibers, adhesives, resin matrix, insulating materials, functional materials, composite materials, etc.

The performance of polyimide is strongly dependent on its chemical structure. Polyimides with different structures can be selected or synthesized according to the application, and can also be modified by copolymerization, blending, filling and reinforcement. The development of new polyimide is inseparable from the development of new monomers. Diamine and dianhydride monomers with special structures are the necessary guarantee for the development of new types of polyimide. Reducing the cost of monomers is the key to reducing polyimide. .

Since polyimide-related materials have an irreplaceable role in sensitive fields such as aerospace, military, and high-end electronics, most foreign polyimide raw materials, technologies and products are strictly blocked in my country. Although domestic enterprises are already working hard to catch up, there is still a big gap between our localized and mass-produced high-end products and the advanced level of foreign countries. Therefore, it is very urgent to vigorously develop polyimide related products, and there is a long way to go!