Performance comparison of aerogel insulation felt

- 2022-08-12

Aerogel

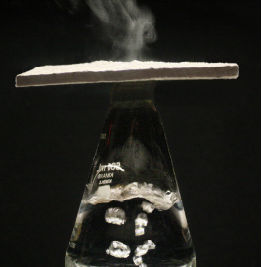

SiO2 aerogel is a highly dispersed solid three-dimensional nanomaterial, which is currently known as the solid material with the lowest thermal conductivity. Aerogel is also known as "blue smoke" because of its light and haze color. It shows many peculiar properties in the fields of heat, optics, electricity, mechanics, and acoustics, and is known as "the magical material that changes the world". It was first obtained by the American scientist Kistler in 1931 by the method of hydrolyzing water glass. With the deepening of aerogel research and the gradual improvement of supercritical drying technology, the solid particles that constitute the aerogel tend to be more refined, and the micropore distribution tends to be more uniform, so that the density of the material is lower and the porosity is higher.

Aerogel insulation felt

Aerogel thermal insulation felt is a flexible thermal insulation material that combines aerogel materials in a flexible substrate through a special process. The traditional thermal insulation materials mainly include aluminum silicate, glass wool, rock wool, rubber and plastic, polyurethane, etc. In the past few decades, traditional thermal insulation materials have played a huge role in their respective fields, providing thermal insulation for the industry. , reduce energy consumption for urban buildings. With the development of the times and the advancement of science and technology, traditional thermal insulation materials are increasingly unable to meet people's requirements for high efficiency and energy saving, such as poor thermal insulation effect, easy fire, easy aging, and short service life. So are there new insulation materials to replace these traditional insulation materials? That is nano-aerogel insulation felt. Compared with traditional insulation materials, aerogel insulation felt has the following advantages:

Low thermal conductivity

The index to measure the thermal insulation effect of thermal insulation materials is thermal conductivity. The thermal conductivity of aerogel insulation felt is 0.020W(m.K), while the thermal conductivity of traditional thermal insulation materials is 0.028W(m.K)~0.045W(m.K). Low, can achieve the same thermal insulation effect with thinner thermal insulation thickness.

The use of aerogel insulation felt can effectively reduce the thickness of the wrapping layer and reduce heat loss.

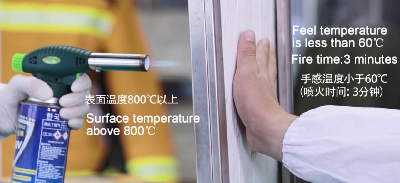

Class A non-combustible fire rating

Aerogel insulation felt is an inorganic material with completely non-combustible Class A fire resistance, while among traditional insulation materials, rubber, plastic and polyurethane are organic materials that are prone to fire.

Good waterproof effect

The aerogel insulation felt has a hydrophobicity rate of over 99%, and allows water vapor to pass through. It has unique hydrophobic air permeability. Therefore, it can effectively reduce the generation of condensation during use and avoid corrosion under the insulation layer to the greatest extent (CUI). ). However, traditional thermal insulation materials are very easy to absorb water during use, resulting in an increase in thermal conductivity, a decrease in thermal insulation effect, and corrosion of the pipeline layer.

Wide temperature range

Aerogel insulation blankets can be used in a wide range of temperatures, ranging from -200°C low temperature to 650°C high temperature. In the traditional thermal insulation materials, ordinary rubber and plastic can reach the lowest temperature of -40 °C, while the high temperature can only reach 120 °C; in the high temperature field, aluminum silicate can withstand high temperature up to 800 °C, but not low temperature, and most other thermal insulation materials. , the highest temperature is only about 100 ℃.

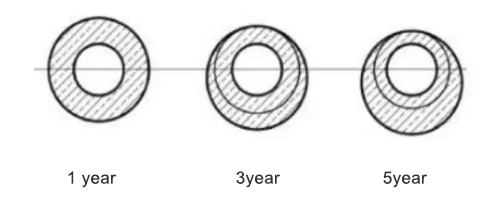

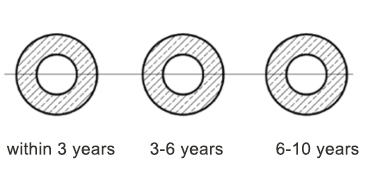

Long lasting

The service life of aerogel insulation felt is more than 15 years, which is 3-5 times that of traditional materials, which can effectively reduce the cost of replacing insulation materials and the cost of construction and operation. Aluminum silicate and rock wool in traditional thermal insulation materials will collapse in structure after 3-5 years of use, resulting in an increase in thermal conductivity, and the thermal insulation material needs to be replaced. The figure below shows the comparison of the collapse of traditional insulation materials and aerogel insulation felt structures:

traditional insulation materials

Aerogel insulation felt

Application scenarios

-

Long-distance transmission heat pipe network

Steam pipeline network, such as thermal power plants, oil exploration enterprises, etc.

Primary pipe network for urban central heating

-

Space Constrained Adiabatic Scenarios

Main equipment of power station such as gas turbine and steam turbine

Integrated pipe gallery

Buried steam pipelines

Arrange well-proportioned pipes

-

High temperature and high humidity environment

Thermal, chemical and other enterprises in the southern coastal areas

Layout pipelines in trenches (to solve the problem of CUI corrosion under the insulation layer)

-

Fire and thermal insulation dual requirements

new energy vehicles

Power battery (battery case)

Fire and smoke exhaust pipes

Applications

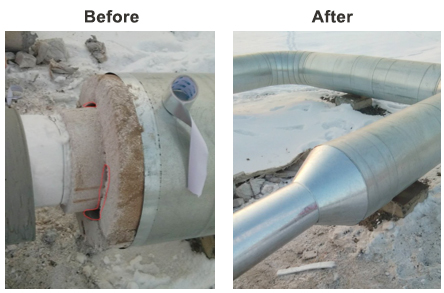

The steam boiler insulation pipeline of a petrochemical mining enterprise originally used 200mm two-layer composite silicate tiles for insulation. The diameter of the pipe is Φ130, the medium in the pipe is steam, and the normal operating temperature is about 310 °C. After years of operation, the insulation effect of the pipeline decreases, and the local heat loss is serious. The 40mm aerogel insulation felt of Zhongning Technology was used for replacement and the thermal insulation test was carried out. The test results showed that the thickness of the aerogel insulation felt was thinner than that of the original composite silicate, and the energy saving rate reached 45%.

Therefore, the use of aerogel thermal insulation materials in the heating pipe network has good thermal insulation effect, low pipeline heat dissipation loss, and obvious energy saving and emission reduction effects. At the same time, aerogel materials have the advantages of long service life, convenient construction, safety and environmental protection, etc. It is an important means to solve the difficulty of thermal insulation of steam pipelines.