-

-

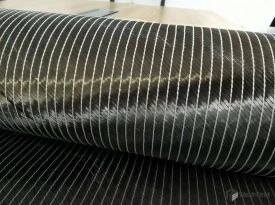

Carbon fiber filaments - 6k

- کوڈنگ :TC-CF-6K

- مواد :100% Carbon Fiber

- وزن :6k filaments

- فنکشن :High strength, Low weight.

- رنگ :Black

مشورہ

Characteristics of 6K carbon fiber filament:

1. Performance:

- High strength and high modulus: It has high tensile strength and modulus, and its strength is significantly higher than many traditional materials. Its tensile strength is about 2 to 7GPa, and its tensile modulus is about 200 to 700GPa. This makes it not easy to deform when subjected to external forces, and can be used in occasions where high material strength and stiffness are required.

- High temperature resistance: It can maintain stable performance at higher temperatures, and can generally be used normally in environments above 200℃. When the temperature is higher than 1500℃, the strength begins to decrease, and the higher the temperature, the greater the fiber strength, which is suitable for some high-temperature working environments.

- Corrosion resistance: It has good resistance to acids, alkalis, organic solvents, etc., and can still maintain stable performance in harsh chemical environments. It can be used in corrosive environments such as chemical industry and ocean.

- Good conductivity: It is a good conductive material that can effectively conduct current and heat, and can be used in fields that require conductivity or anti-static.

- Lightweight: The density is about 1.5 to 2.0 grams per cubic centimeter, which is lighter than aluminum and less than 1/4 of steel. The specific strength is 20 times that of iron, which makes the products made of 6K carbon fiber filament light, easy to transport and install, and also helps to reduce energy consumption.

- Fatigue resistance: It has good fatigue resistance and can maintain good performance under long-term cyclic loads, extending the service life of the product.

2. Processing:

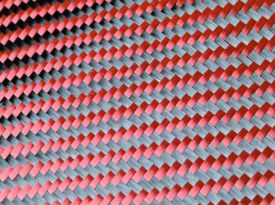

- Good weavability: It can be woven to make fabrics of various shapes and structures, such as two-dimensional plain, twill, satin fabrics, and three-dimensional stereo fabrics. The woven carbon fiber fabric has high strength and stiffness, as well as good flexibility and processability.

- Good compatibility with resin: It has good compatibility with matrix materials such as epoxy resin and polyester resin, and can be combined with resin by impregnation, coating, etc. to form carbon fiber reinforced composite materials.

Main uses of 6K carbon fiber filament:

1. Aerospace:

used to manufacture structural components of aircraft, satellites, rockets and other aircraft, such as wings, fuselages, engine blades, satellite brackets, etc. Its excellent performance can meet the strict requirements of the aerospace field for material performance, and help improve the performance and reliability of aircraft.

2. Automobile industry:

can be used to manufacture automobile body structural parts, engine parts, drive shafts, brake systems, etc. The use of carbon fiber filaments can reduce the weight of the car, reduce fuel consumption and exhaust emissions, and improve the safety and comfort of the car.

3. Sports goods:

widely used in the manufacture of sports equipment such as golf clubs, tennis rackets, bicycles, skis, etc. These equipment need to have the characteristics of light weight and high strength to improve the athletes' experience and competitive performance.

4. Construction field:

can be used for building reinforcement, such as strengthening the structure of buildings such as bridges and houses to improve their bearing capacity and seismic resistance. In addition, it can also be used to manufacture building materials, such as carbon fiber reinforced cement, etc.

5. Electrical heating field:

Due to its good electrical conductivity and high temperature resistance, it can be used to manufacture conductive paper, electric heating plates, batteries and other electric heating products.

6. Industrial manufacturing:

In the industrial fields of machinery manufacturing, electronic equipment, etc., it can be used to manufacture molds, fixtures, transmission shafts and other parts, as well as electronic equipment shells, radiators, etc.

Advantages and disadvantages of 6K carbon fiber filament:

- Advantages:

- Excellent performance: high strength, high modulus, high temperature resistance, corrosion resistance, good electrical conductivity and other excellent properties make it have irreplaceable advantages in many fields, and can meet some application scenarios with extremely high requirements for material performance.

- Significant weight reduction effect: The light weight can reduce the weight of the product, which is of great significance for weight-sensitive fields such as aerospace and automobiles, and can improve fuel efficiency and reduce energy consumption.

- High design flexibility: Good processability and weavability allow designers to process 6K carbon fiber filaments into products of various shapes and structures according to different needs to meet diverse design requirements.

- Disadvantages:

- High cost: The production process is complicated and the raw materials are expensive, resulting in a high cost of 6K carbon fiber filaments, which limits its application in some cost-sensitive fields.

- Brittleness: Although it has high strength, carbon fiber filaments are brittle and have poor impact resistance. They are prone to breakage or damage when subjected to large impact forces.

- Difficult processing: The requirements for processing technology and equipment are high, and professional processing technology and equipment are required, otherwise it is easy to affect the quality and performance of the product.

- Difficult recycling: It is difficult to recycle carbon fiber composite materials, and there is no mature recycling technology and system yet, which puts a certain pressure on the environment.

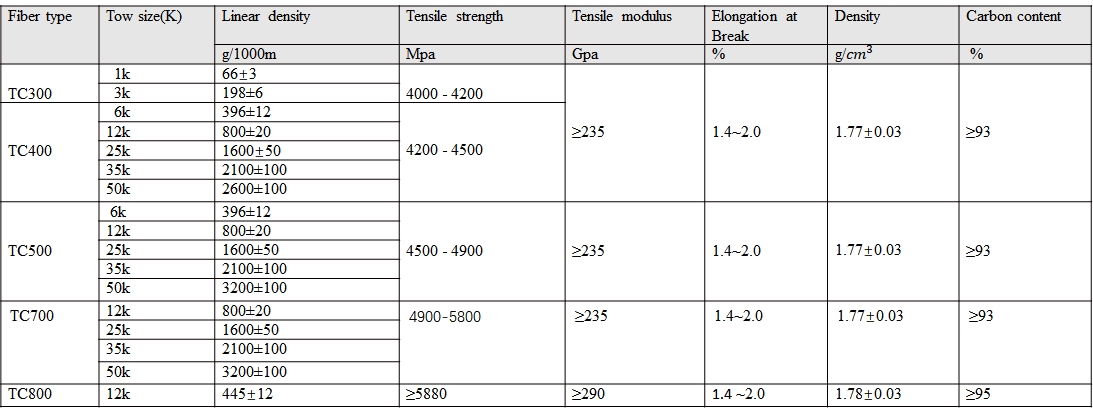

Technical Data

Production Line

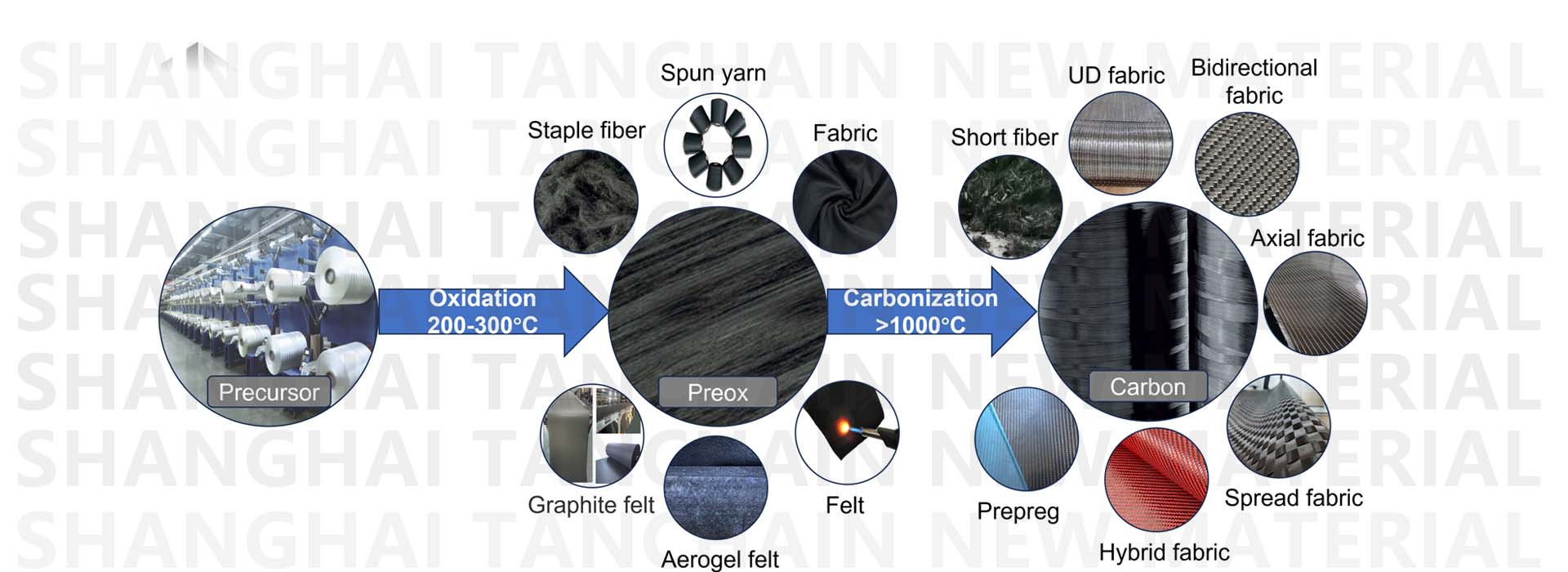

Tanchain's Production Flow

SHIPPING