-

-

3K Plain Carbon Fabrics - 240gsm

- kodning :TC-CF-3KC240P

- Material :100% Carbon Fabric

- vikt :240GSM

- Fungera :exterior and interior fabric for sports equipment, automobiles, furniture decoration, etc.

- Färg :Black

- Väva :Plain

- bredd :10~150CM

rådfråga

Product Properties

3K 240g carbon fiber fabric has the following features:

1. Material properties:

- High strength:

The strength of carbon fiber is about 10 times that of steel. 3K 240g carbon fiber fabric also has excellent tensile strength and can withstand large stress and tension. It can be used in occasions that require high material strength.

- Low density:

Low density is one of the distinctive features of carbon fiber. Its density is only 1/5 of steel and about 1/2 of aluminum alloy. This low density gives 3K 240g carbon fiber fabric a great advantage in terms of weight and is suitable for weight-sensitive application scenarios, such as aerospace, automotive and other fields. It can effectively reduce the overall weight and improve the performance and efficiency of equipment.

- High modulus:

Modulus reflects the material's ability to resist deformation under stress. The fabric has a high modulus, is not prone to deformation, and can maintain good dimensional stability and structural integrity.

- Good corrosion resistance:

Carbon fiber has good corrosion resistance to general organic solvents, acids, and alkali, and does not dissolve or swell. In harsh chemical environments, 3K 240g carbon fiber fabric can maintain stable performance and is not susceptible to corrosion, extending its service life.

- High temperature resistance:

Carbon fiber has high high temperature resistance and can still maintain good mechanical properties and structural stability in high temperature environments. This makes the fabric have application potential under high-temperature working conditions, such as aircraft engine peripheral parts, high-temperature stoves and other fields.

2. In terms of weaving technology:

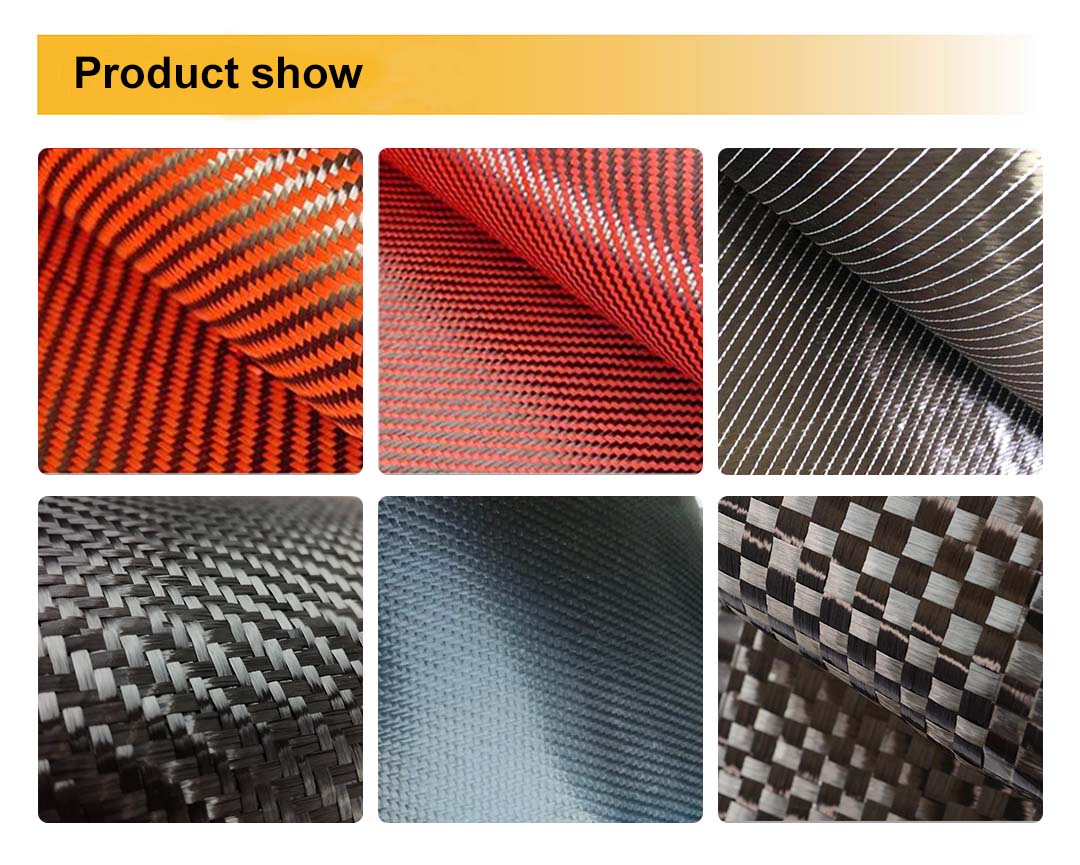

- Delicate texture: 3K represents 3,000 single-filament carbon fiber filaments in a bundle of carbon fibers. The fiber bundle is thinner, and the woven texture is more delicate and uniform. This delicate texture not only makes the appearance of the fabric more beautiful, but also improves the surface quality and smoothness of the material, making it suitable for products with higher appearance requirements.

- Good formability: Due to the thin fiber bundles, 3K 240g carbon fiber fabric is easier to fit the shape of the mold during the molding process and has good formability. Whether it is a simple plane shape or a complex curved surface structure, it can be formed well, providing greater freedom for product design and manufacturing.

3K 240g carbon fiber fabric has a wide range of application scenarios, including:

1. Aerospace field:

In aerospace equipment such as aircraft, satellites, and rockets, there are extremely high requirements for the weight, strength, and high temperature resistance of materials. 3K 240g carbon fiber fabric can be used to manufacture aircraft wings, fuselage structural parts, engine blades and other components, which can reduce the weight of the aircraft and improve flight performance and fuel efficiency; satellite structural frames, solar panel brackets, etc. can also be used This fabric is designed to meet the needs of use in space environments.

2. Automobile industry:

The automobile industry pursues lightweighting to improve fuel economy and performance. 3K 240g carbon fiber fabric can be used for automobile body structural parts, engine parts, interior parts, etc. For example, car bumpers, roofs, doors, etc. can use carbon fiber materials to replace traditional metal materials to reduce the weight of the car body and improve the collision safety of the vehicle; the use of carbon fiber fabrics for car seats, steering wheels and other interior parts not only It can reduce weight and improve the grade and texture of the interior.

3. Sporting goods:

In the field of sporting goods, 3K 240g carbon fiber fabric is often used to manufacture high-end bicycles, golf clubs, tennis rackets, fishing rods, etc. These sports equipment need to be high-strength and lightweight to improve athletes' experience and competitive performance. For example, the frame of a carbon fiber bicycle is made of this fabric, which can make the bicycle lighter and stronger, making it easier for athletes to ride; the shaft of a golf club is made of carbon fiber material, which can increase the elasticity of the club and the hitting distance.

4. Construction field:

In terms of strengthening and repairing building structures, 3K 240g carbon fiber fabric can be used as a high-performance reinforcement material. Due to its high strength and good bonding properties, it can be used to reinforce concrete structures, bridges, tunnels and other buildings to improve the load-bearing capacity and durability of the structure.

5. Electronic equipment field:

As electronic equipment continues to be miniaturized and lightweight, the requirements for materials are becoming higher and higher. 3K 240g carbon fiber fabric can be used to manufacture the casings and internal structural parts of electronic devices such as mobile phones, tablets, and laptops. It can not only provide sufficient strength and stability, but also reduce the weight of the device and make it easy to carry.

Material: |

100% carbon fiber | Yarn (warp): | 3k carbon fiber |

| Pattern: | Plain | Yarn (weft): | 3k carbon fiber |

| Weight : | 240gsm | Width: | 10-150cm |

| Density(warp): | 6/10cm | Thickness: | 0.36mm |

| Warp tensile strength | >960N/25mm | Weft tensile strength | >720N/25mm |

| Density(weft): | 6/10cm | Color: | Black |

Material: |

100% carbon fiber |

| Pattern: | Plain |

| Weight : | 240gsm |

| Density(warp): | 6/10cm |

| Density(weft): | 6/10cm |

| Yarn Count(warp): | 3k carbon fiber |

| Yarn Count(weft): | 3k carbon fiber |

| Width: | 10-150cm |

| Warp tensile strength | >960N/25mm |

| Weft tensile strength | >720N/25mm |

| Thickness: | 0.36mm |

| Color | Black |

| Content: | 100% carbon fiber |

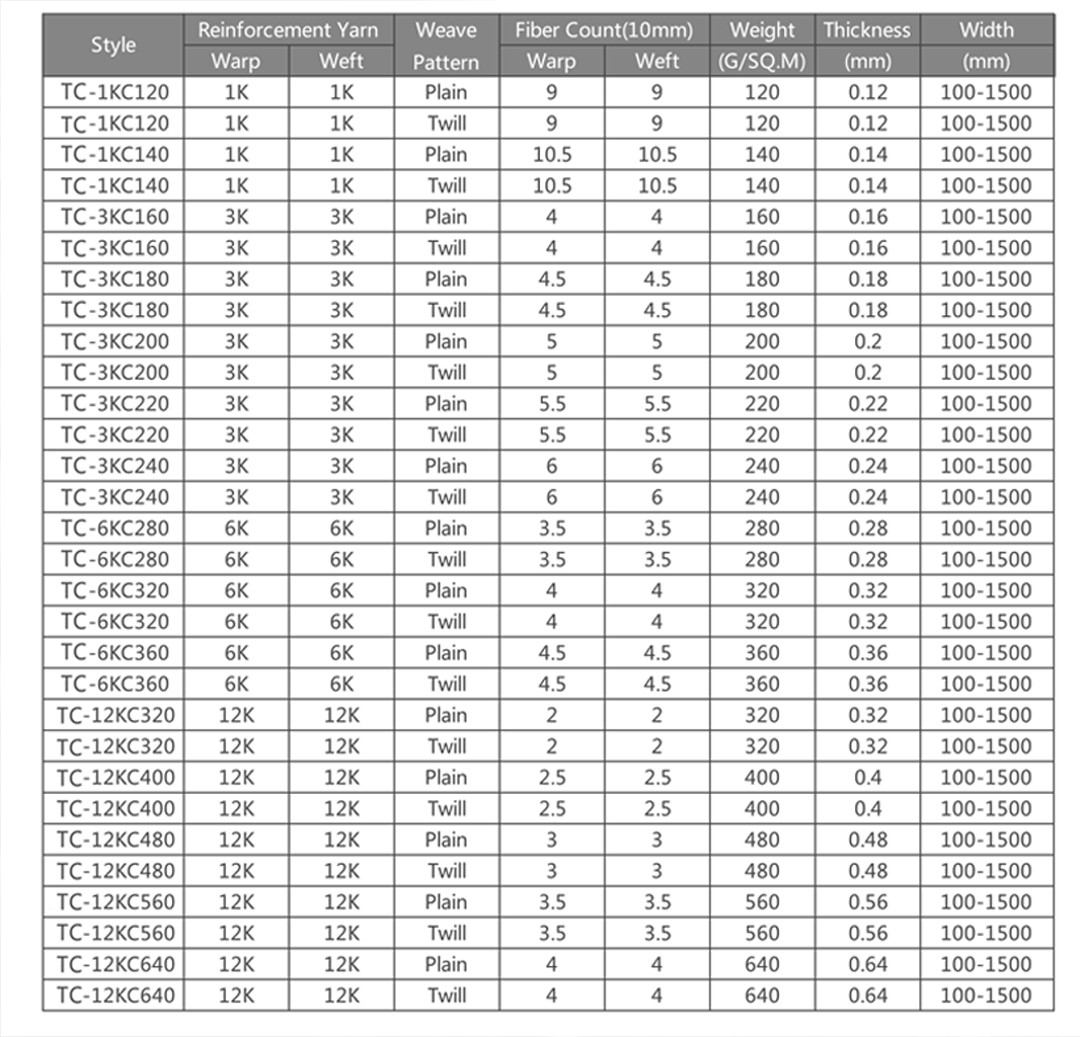

| Specification : | 1k-12k, 120-640gsm |

| Color: | Black |

| width: | 10-150cm, customized width is available |

| Feature: | High tensile strength, high modulus, strong durability and corrosion resistance, low thermal expansion, high stiffness, high impact resistance, conductivity, good shock absorption |

| MOQ: | 100m |

| Meet standard : | AATCC/ASTM, EN, ISO, GB, AS |

| Application : | Used in car, trains, transportation, building reinforcement, sports equipment, aerospace, drive shafts, Reinforcement |

Similar Series Technical Data