-

-

PAN precursor of carbon fiber - 12k

- 코딩:TC-PAN-12K

- 재료:100% Polyacrylonitrile(PAN)

- 무게:12k filaments

- 기능:The precusor of carbon fiber

- 색깔:white

찾다

There are mainly the following types of carbon fiber precursors:

- Polyacrylonitrile-based carbon fiber precursor:

It is formed by spinning, pre-oxidation, carbonization and other stages of polyacrylonitrile. It has the characteristics of high strength, high stiffness, light weight, high temperature resistance, corrosion resistance, excellent electrical properties, etc. It has strong compression and bending resistance and occupies a dominant position in reinforced composite materials. Its output accounts for more than 90% of the total output of carbon fiber.

- Asphalt-based carbon fiber precursor:

It is made of petroleum asphalt or coal asphalt as raw materials, and is made by refining, spinning, pre-oxidation, carbonization or graphitization of asphalt. The production cost of raw materials is lower than that of polyacrylonitrile-based carbon fiber.

- Viscose-based carbon fiber precursor:

It is obtained by dehydration, pyrolysis and then carbonization of viscose fiber whose main component is cellulose.

- Vapor-grown carbon fiber precursor:

It is made of benzene, methane and other raw materials, with transition metals such as iron, cobalt, nickel and their alloys and compounds as catalysts, and hydrogen as carrier gas in a reducing atmosphere.

Compared with other carbon fiber precursors, 12k polyacrylonitrile-based carbon fiber precursors have the following differences:

Tow specifications

12k means that one bundle of the carbon fiber precursor contains 12,000 filaments, which is of medium thickness in the specifications of carbon fiber precursors. Compared with small-tow carbon fiber precursors such as 3k, 12k carbon fiber precursors have more filaments and can be used to make large-scale, load-bearing structural parts.

Production process

The production process of 12k polyacrylonitrile-based carbon fiber precursors is relatively mature and stable, and the production efficiency is high, which can meet the needs of large-scale industrial production. The production process of large-tow precursors above 24k is more difficult, and there are problems such as high wire breakage rate and poor production stability during the production process.

Performance

The carbon fiber made of 12k polyacrylonitrile-based carbon fiber precursors has good comprehensive performance in terms of strength and modulus, which can meet the use requirements of most industrial and civilian fields. Although its strength and modulus are slightly lower than some high-performance small-tow carbon fibers, it has achieved a good balance between cost and performance and has a high cost-effectiveness ratio.

Appearance and texture

The fabric or composite material made of 12k polyacrylonitrile-based carbon fiber precursor has a relatively rough appearance texture, and the surface is not as smooth and delicate as the products made of 3k and other small-tow carbon fiber precursors. However, in some application scenarios where the appearance requirements are not high, the performance and cost advantages of 12k carbon fiber precursor are more prominent.

Price

In the market, the price of 12k polyacrylonitrile-based carbon fiber precursor is usually relatively low, which makes it more competitive in cost-sensitive application fields, can reduce the manufacturing cost of products, and improve the market competitiveness of products.

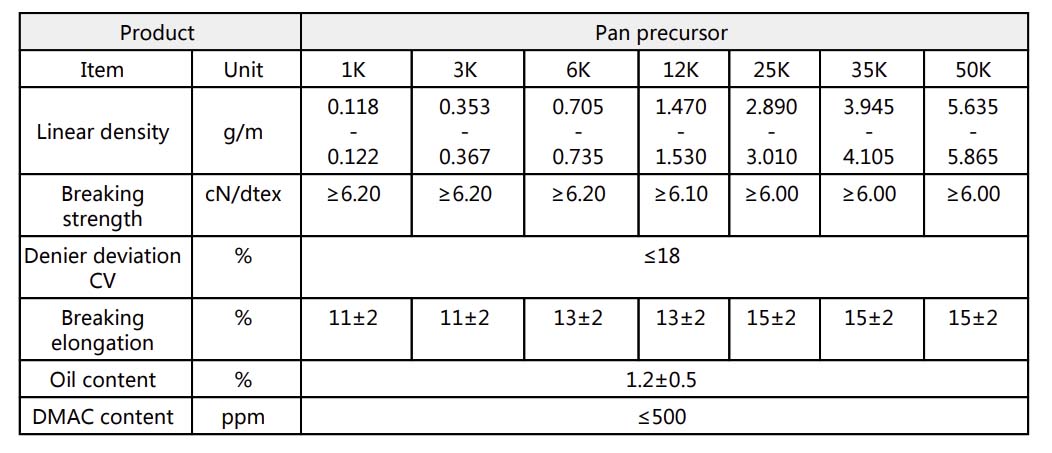

Technical Data Sheet

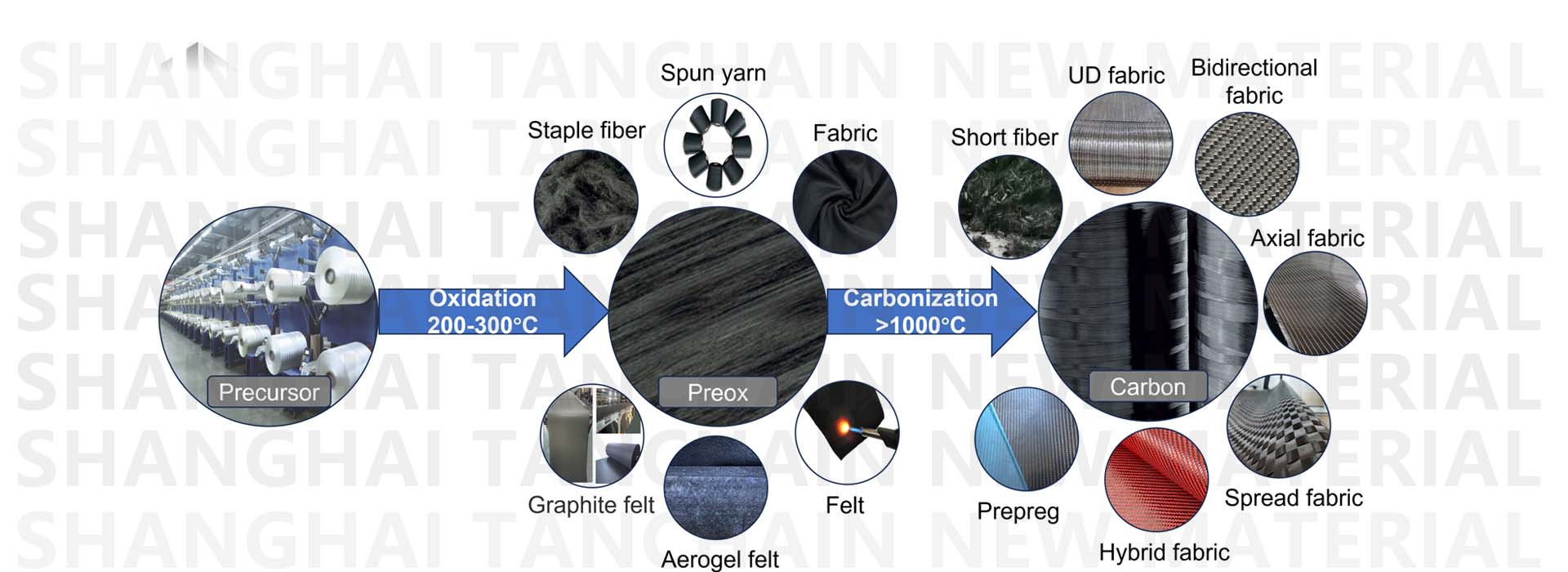

Tanchain's Production Flow

SHIPPING